Research in many fields of modern physics requires micro- or nanoscale devices. Nanofabrication has achieved a truly amazing level of sophistication: physicists routinely deal with atomic-scale materials and devices. Typically, such feats require stringent cleanroom environment: many chemicals used for device fabrication are toxic, while even the tiniest speck of dust can ruin the performance of a field-effect transistor made from 2D materials or a sensor.

Setting up and running a cleanroom is a very hard and expensive undertaking, which makes frontiers of research almost inaccessible to the labs with tight funding and far from established facilities. Prof. Kenneth Burch from Boston College is convinced that this does not need to be the case. His cleanroom-in-a-glovebox proves his point: “The future of cleanrooms is not a cleanroom, it is this”, he says.

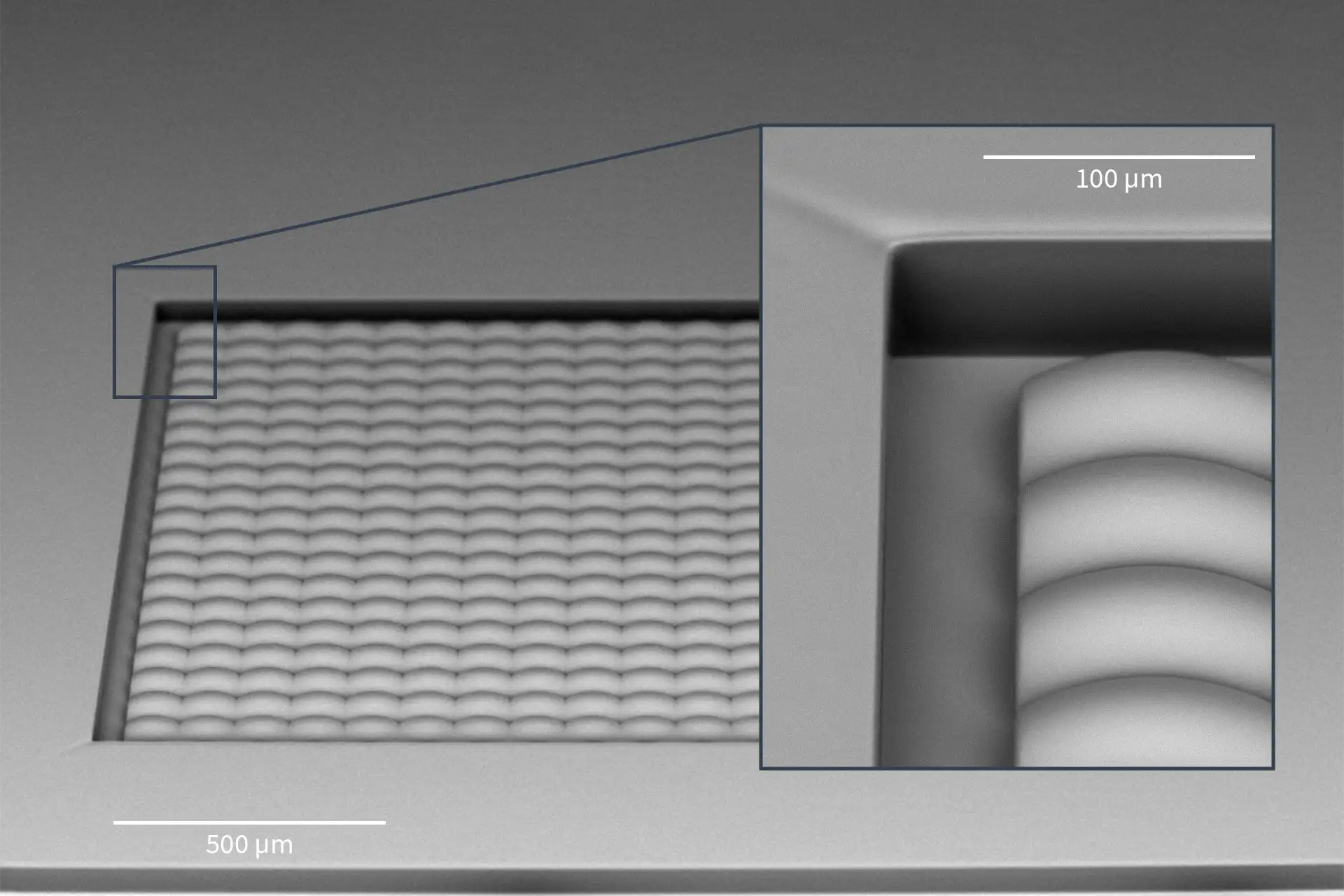

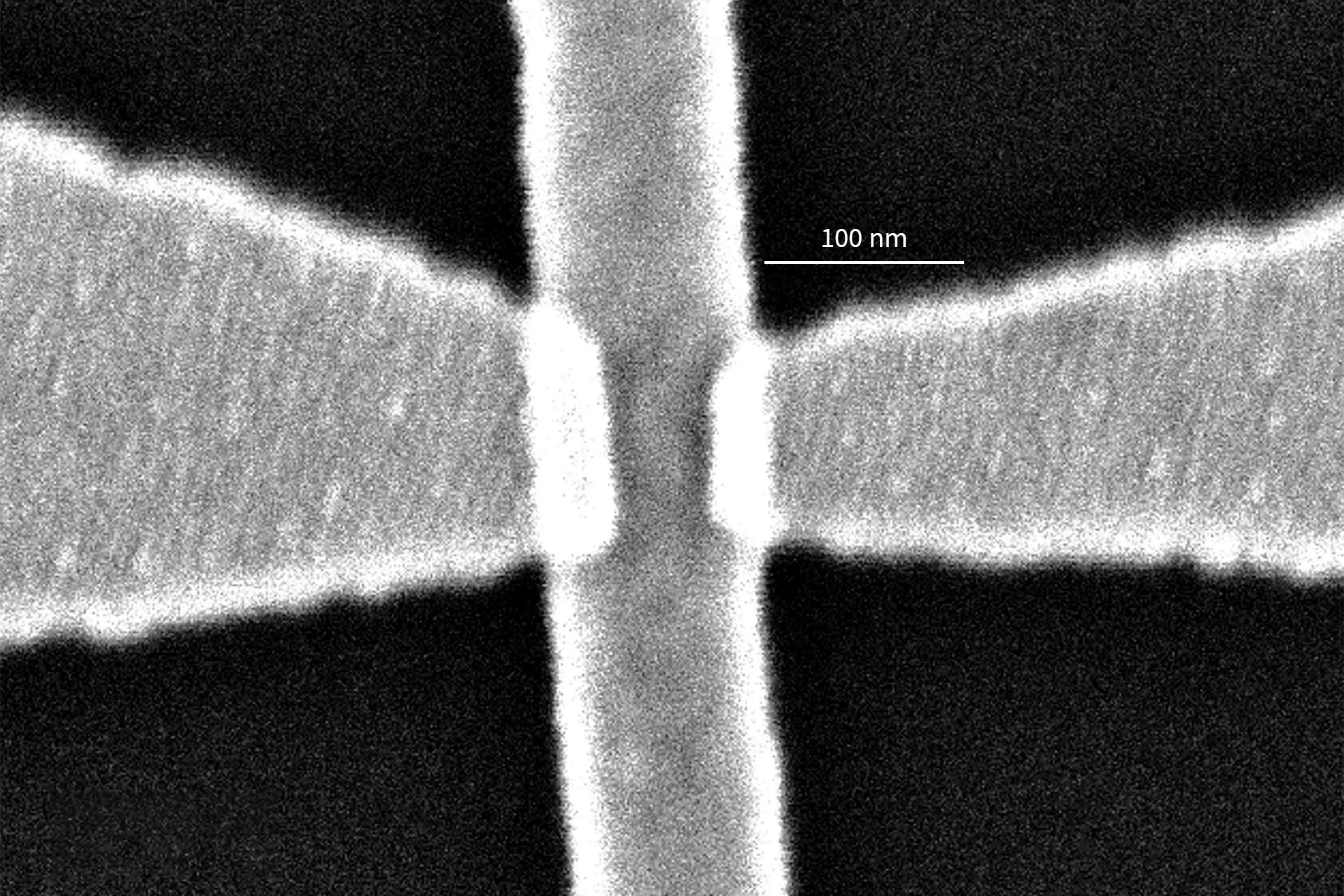

Prof. Burch and his team from the Laboratory of Assembly & Spectroscopy of Emergence have set up a nanofabrication and characterization facility inside a series of interconnected gloveboxes with controlled inert atmosphere. This cleanroom-in-a-glovebox is also equipped with a vacuum suitcase for safely transporting the samples into ultra-high vacuum chambers such as electron beam systems, scanning tunnelling microscopes, molecular beam epitaxy or angle-resolved photoemission spectroscopy tools.

In his interview to The Lithographer, Kenneth Burch talks about how this facility was built and about the research it enables. His team works on 2D topological magnets and superconductors, and on using CVD-grown graphene for biosensing applications. Download the magazine to read the interview in the Quantum issue of The Lithographer, p. 18

Read this edition in our libray:

Select “The Lithographer” in the Category filter.