Materials Science

Lithography for New Materials

-

Description

-

Working with materials at the nano- and micro-scale requires attention to the impact of pattern and device dimensions on material properties.

Direct-Write Lithography offers a flexible method for modifying and shaping materials at these scales, enabling control of a range of physical properties. Heidelberg Instruments’ DWL and MLA series use Direct-Write Laser Lithography to create micro-scale patterns, structures, and textures, as well as contacts for electronic devices and measurements.Additionally, Thermal Scanning Probe-Lithography (t-SPL) can be used to initiate material modifications on the nanoscale, with the added ability to apply local heating. The NanoFrazor provides a highly precise and versatile tool for lithography, allowing ultra-fast heating, cooling, and high local pressure to be applied to materials at the nanoscale, opening up access to states of matter that may not be accessible macroscopically.

These Direct-Write Lithography techniques can be used to study and control the physical properties of materials, with potential applications in fields such as high-performance electronics, energy storage, and water purification. As pattern and device dimensions continue to shrink, direct write lithography offers a promising path towards continued advancement in nanotechnology.

Listed below are some images related to Materials Science and the systems suited for this application.

-

Requirements

-

Patterning on arbitrary materials

Non-invasive lithography

Localized heating

Precise temperature control

-

Solutions

-

Thermal conversion

Used to generate modifications and new materials locally on the nanoscale (NanoFrazor)Accurate overlay

Used to align electrodes onto nanoscale materials without alignment marks (NanoFrazor)No clean room required

High-resolution lithography using novel materialsNon-invasive lithography

Used to preserve physical properties of sensitive materials that would otherwise be damaged or destroyed by irradiation with charged particles or contact with air (glovebox solutions)

Working with materials at the nano- and micro-scale requires attention to the impact of pattern and device dimensions on material properties.

Direct-Write Lithography offers a flexible method for modifying and shaping materials at these scales, enabling control of a range of physical properties. Heidelberg Instruments’ DWL and MLA series use Direct-Write Laser Lithography to create micro-scale patterns, structures, and textures, as well as contacts for electronic devices and measurements.

Additionally, Thermal Scanning Probe-Lithography (t-SPL) can be used to initiate material modifications on the nanoscale, with the added ability to apply local heating. The NanoFrazor provides a highly precise and versatile tool for lithography, allowing ultra-fast heating, cooling, and high local pressure to be applied to materials at the nanoscale, opening up access to states of matter that may not be accessible macroscopically.

These Direct-Write Lithography techniques can be used to study and control the physical properties of materials, with potential applications in fields such as high-performance electronics, energy storage, and water purification. As pattern and device dimensions continue to shrink, direct write lithography offers a promising path towards continued advancement in nanotechnology.

Listed below are some images related to Materials Science and the systems suited for this application.

Patterning on arbitrary materials

Non-invasive lithography

Localized heating

Precise temperature control

Thermal conversion

Accurate overlay

No clean room required

Non-invasive lithography

Application images

suitable Systems

DWL 66+

- Direct Write Laser Lithography System

Our most versatile system for research and prototyping with variable resolution and wide selection of options.

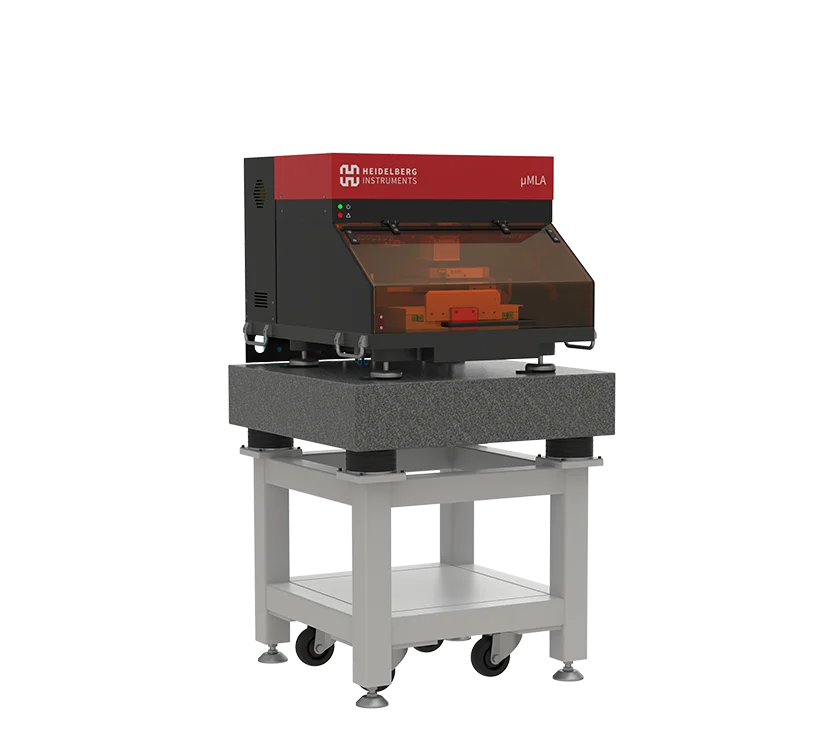

MLA 150

- Maskless Aligner

The fastest maskless tool for rapid prototyping, the alternative to the mask aligners. Perfect for standard binary lithography.

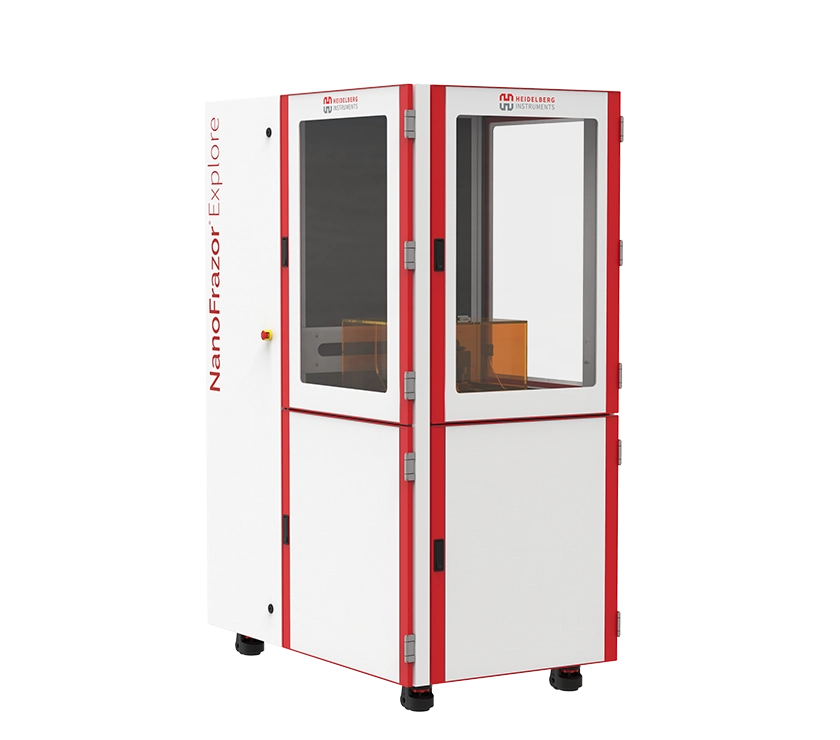

NanoFrazor Explore

- Thermal Scanning Probe Lithography System

Thermal scanning probe lithography tool with direct laser sublimation and grayscale modules. Excellent alternative to e-beam lithography tools.

NanoFrazor Scholar

- Thermal Scanning Probe Lithography System

Table-top thermal scanning probe lithography system with in-situ AFM imaging. Compact and compatible with glovebox.