Micro-optics and Photonics

Reflectors, Diffusors and Microlenses Crafted in Excellence

-

Description

-

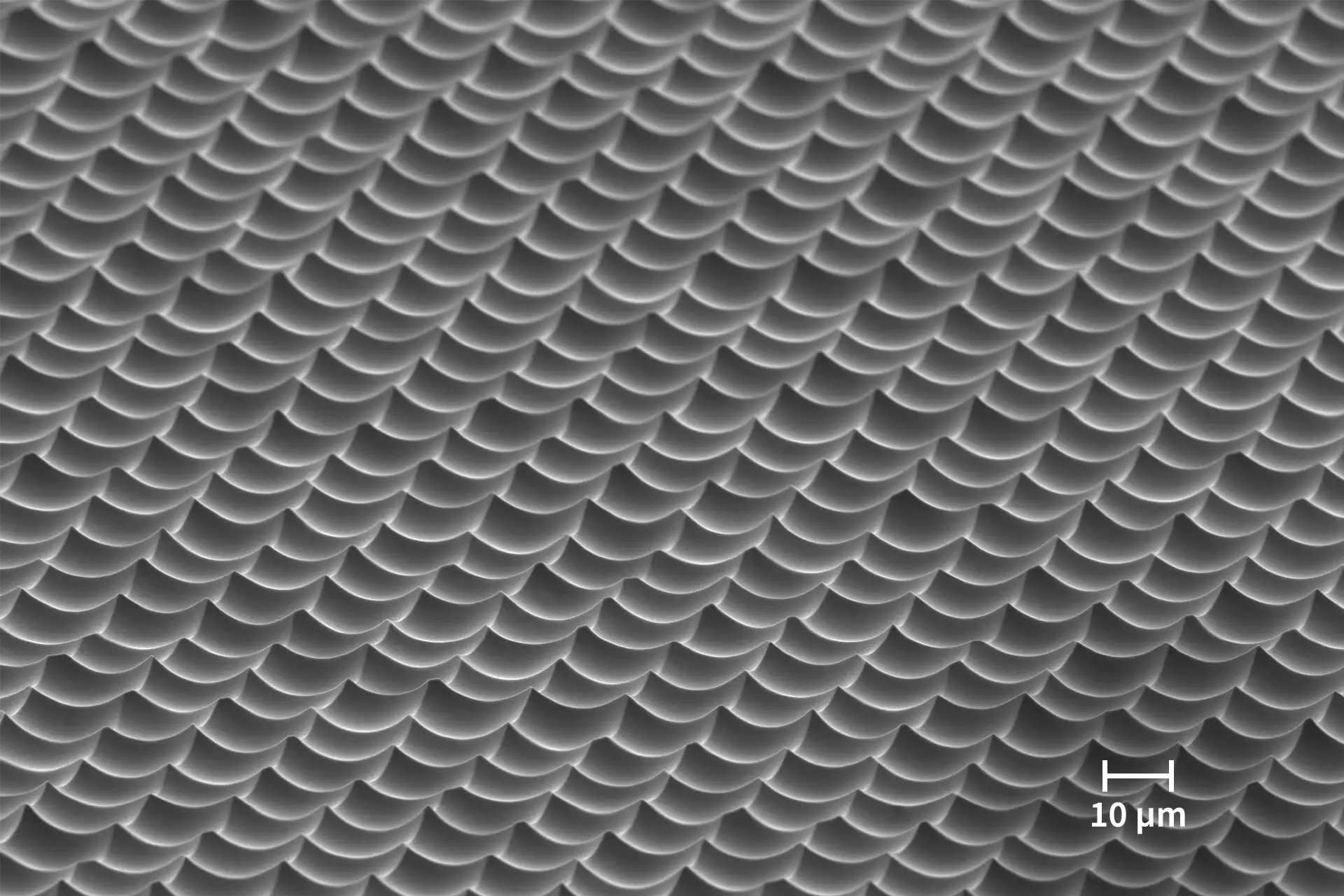

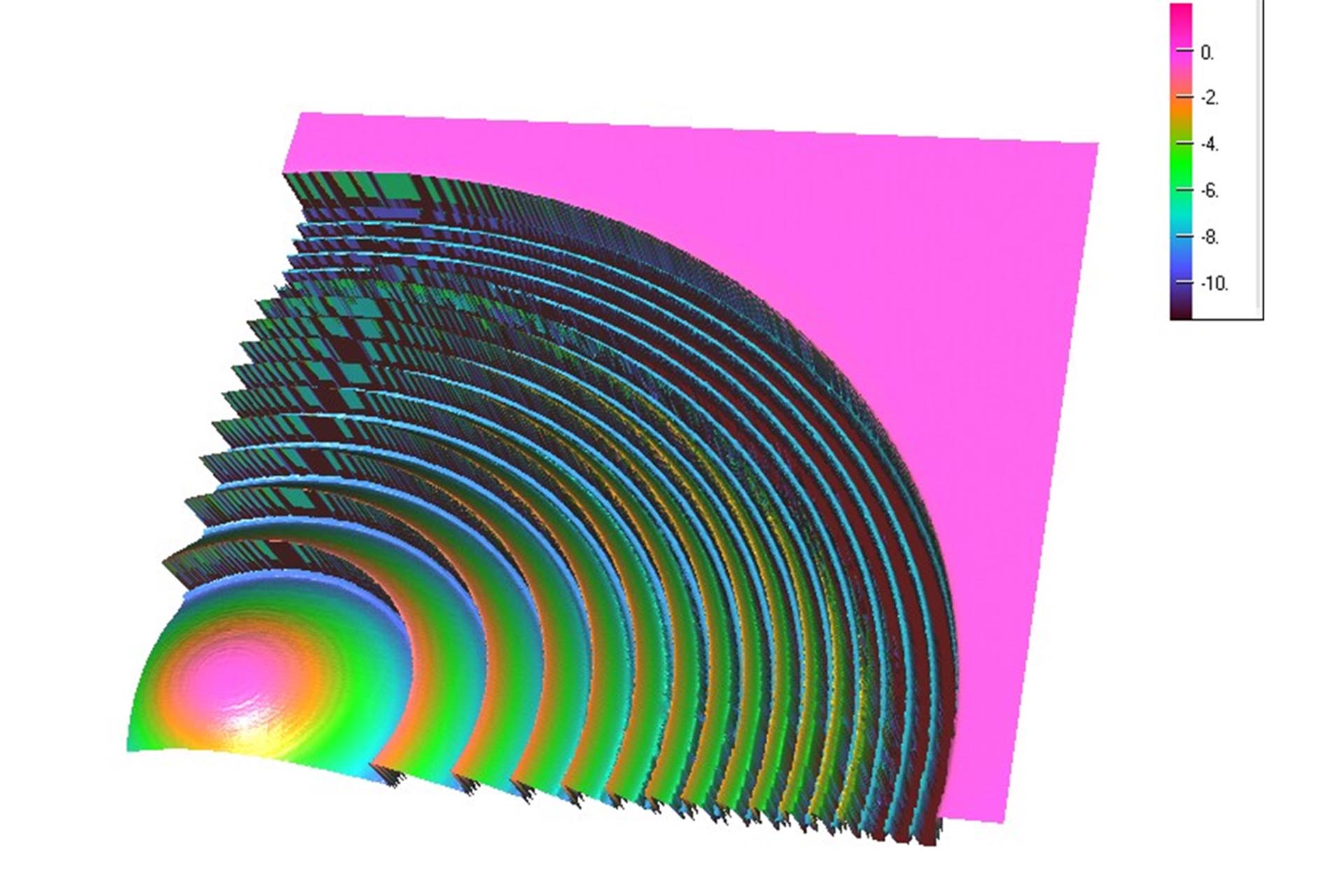

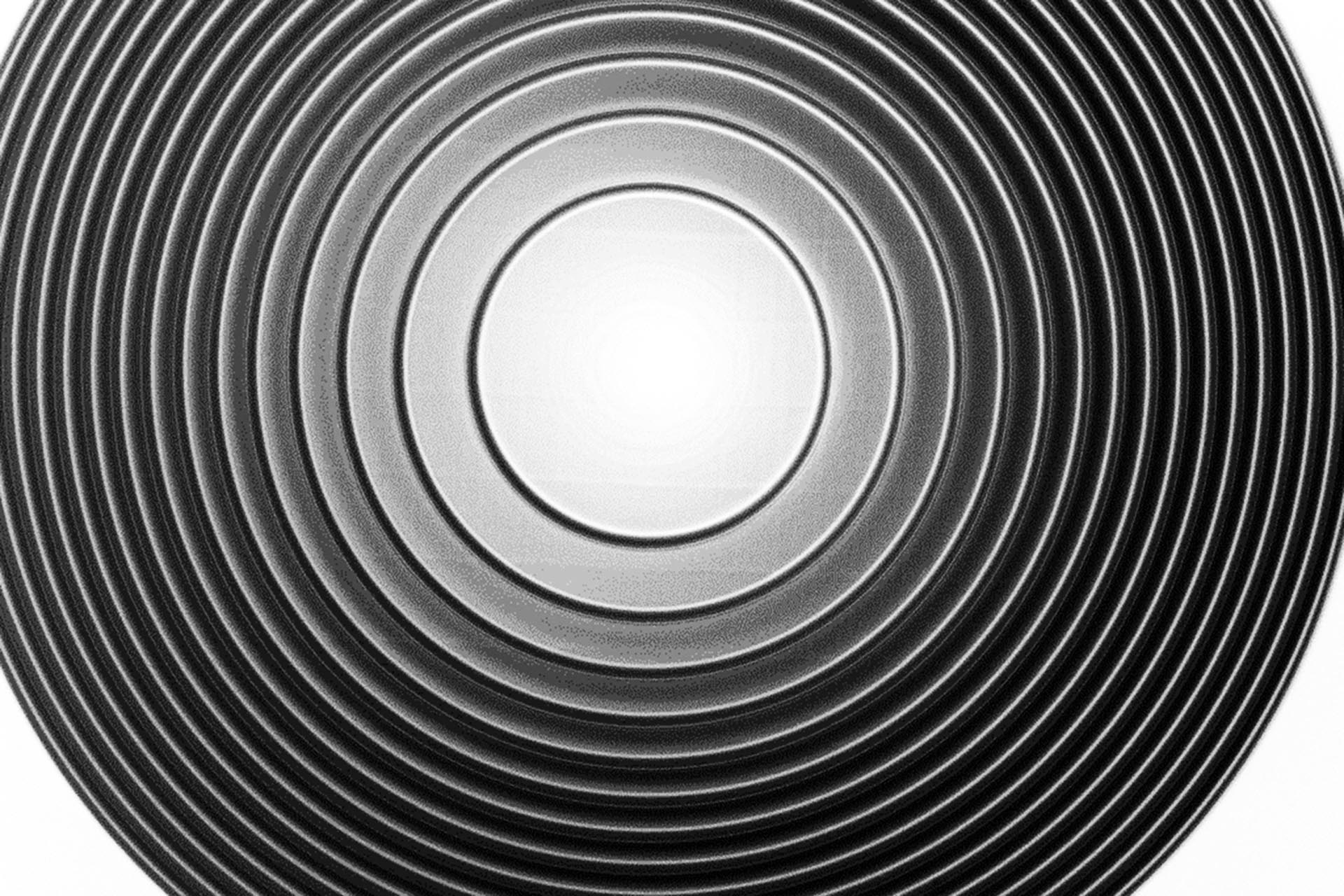

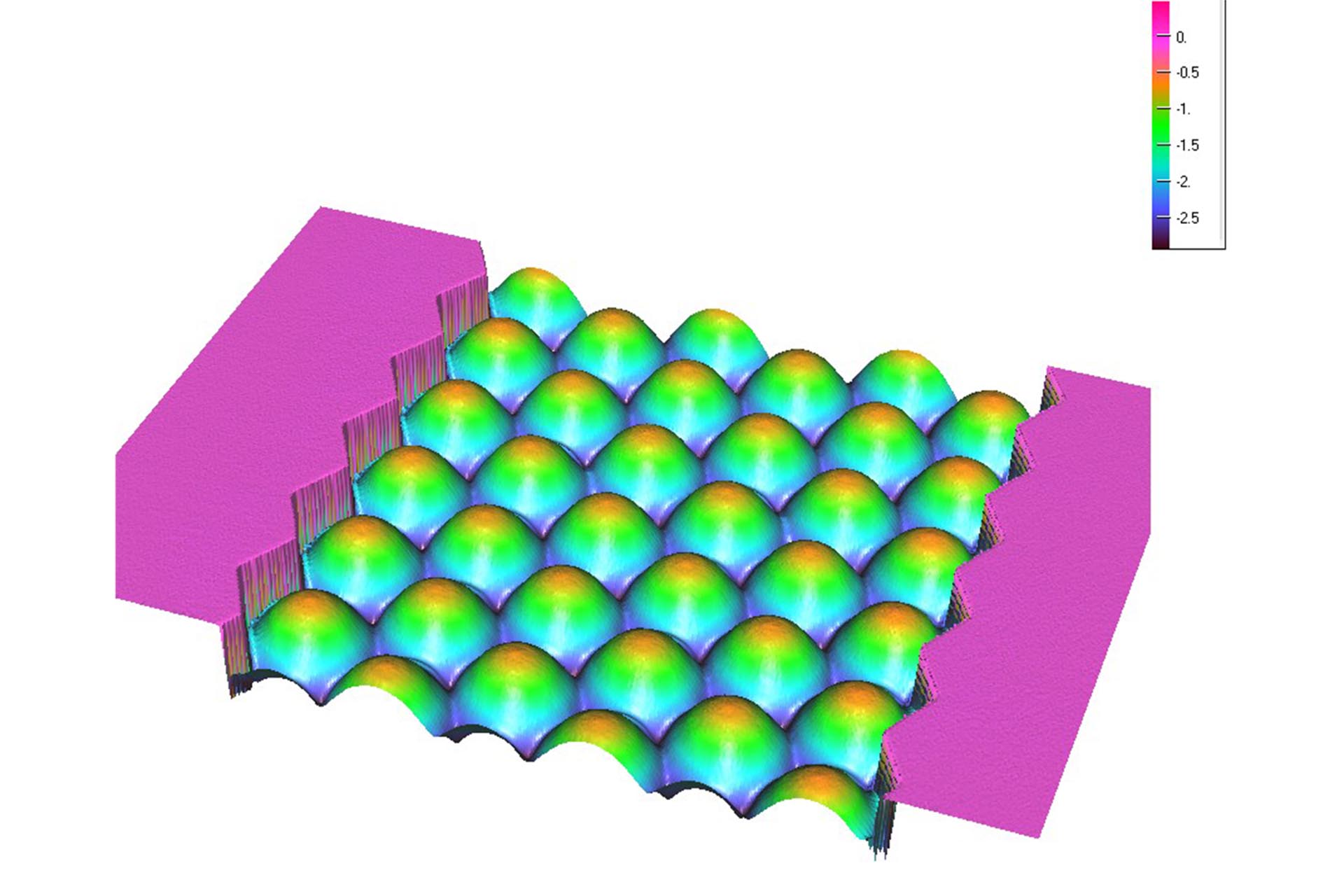

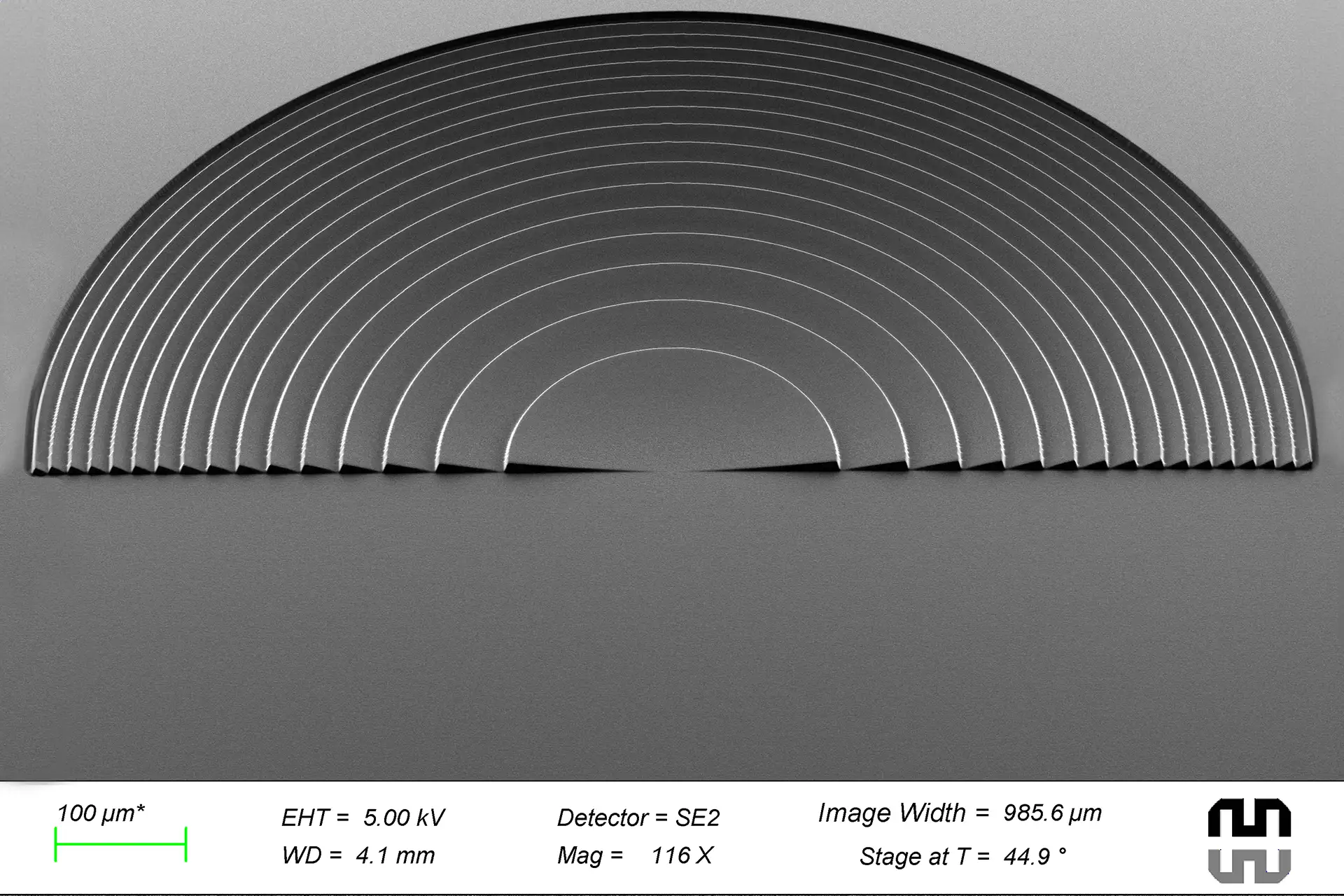

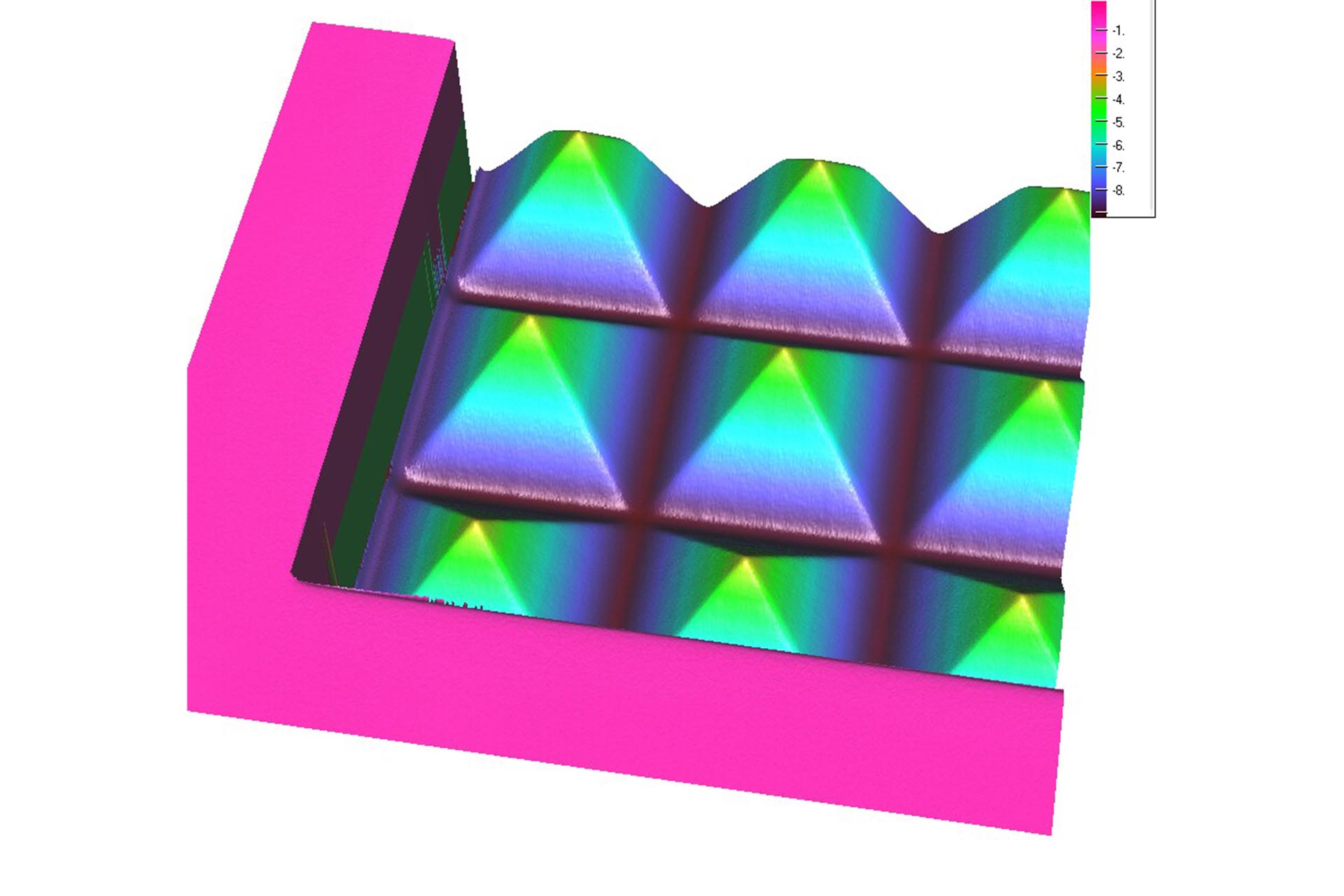

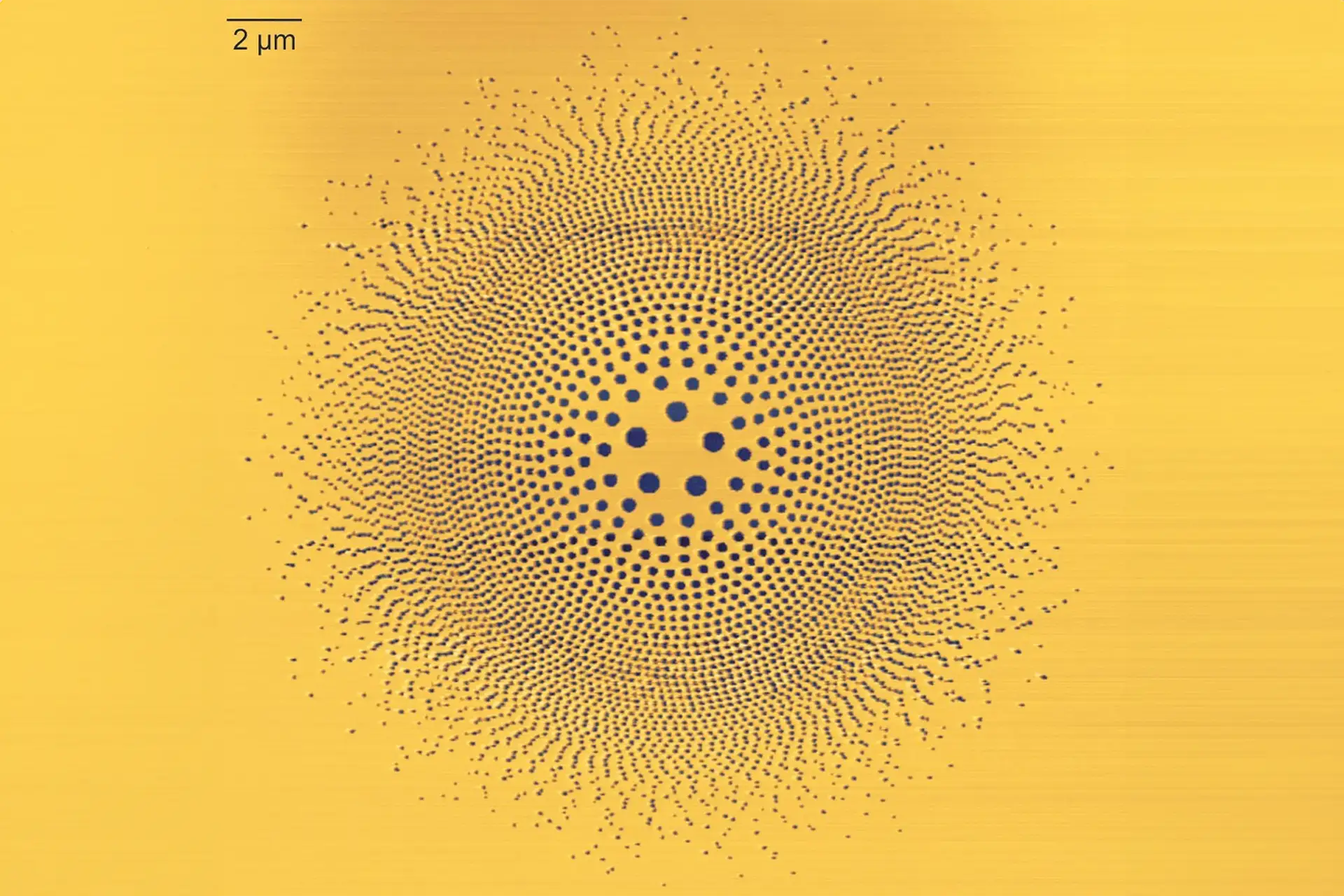

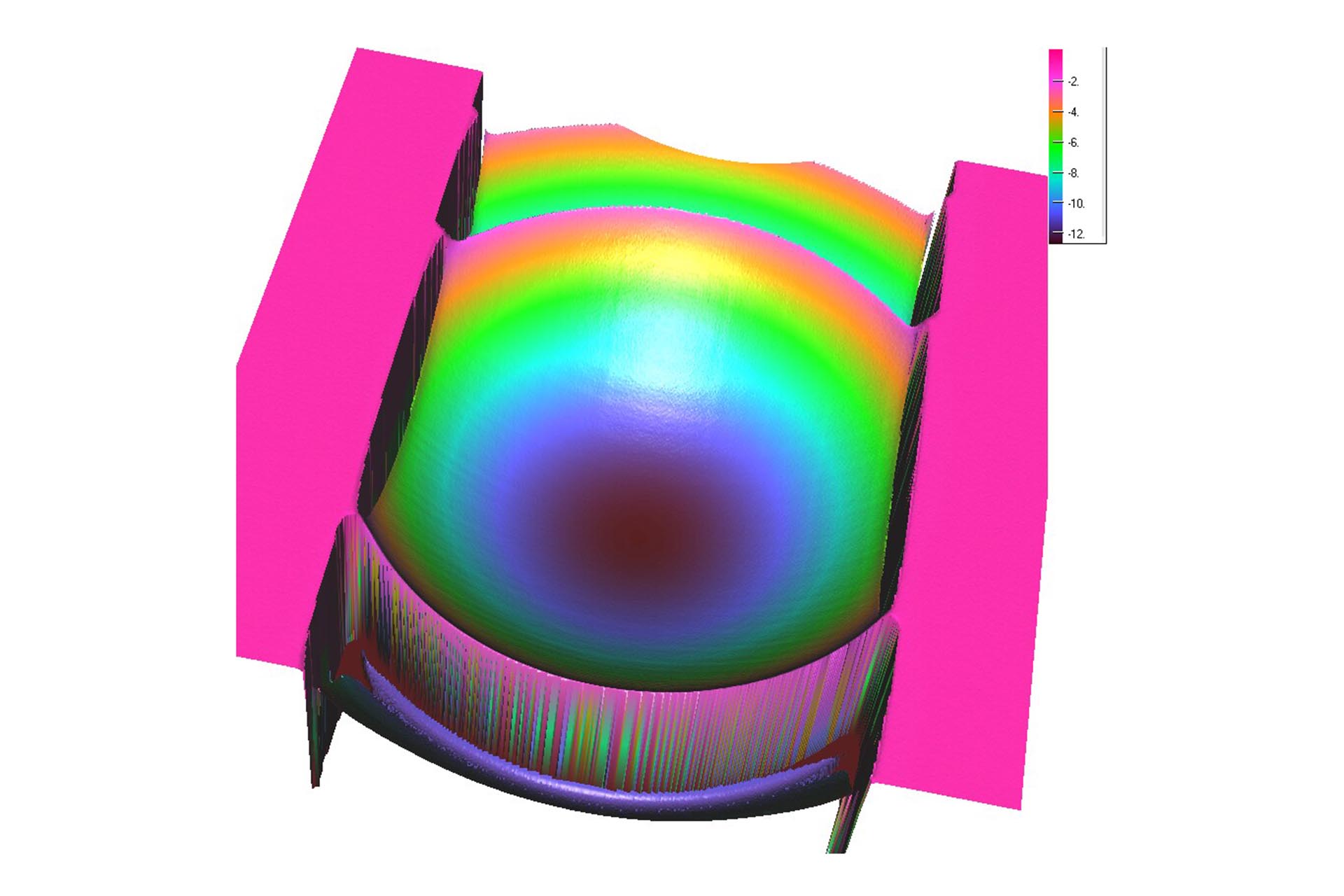

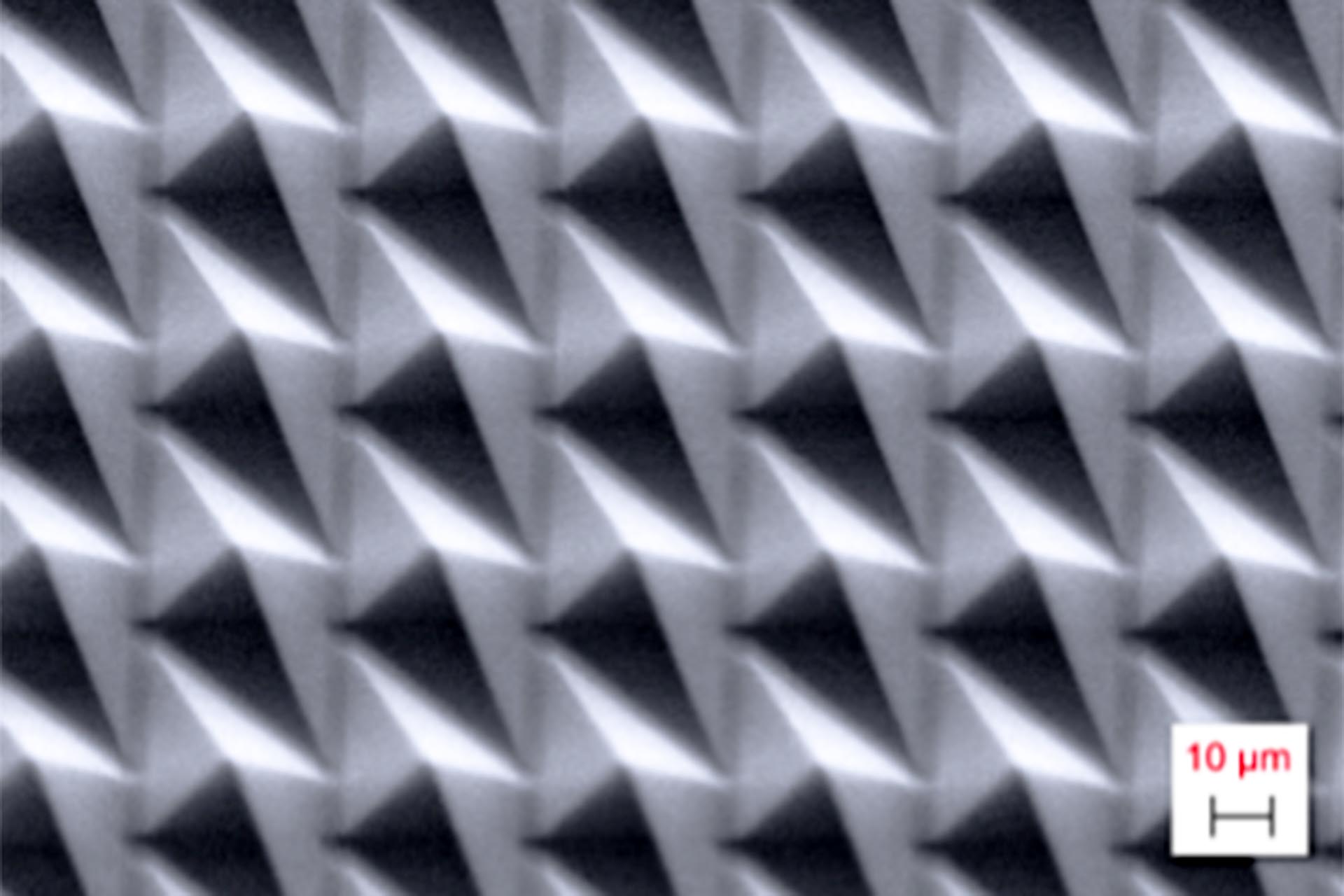

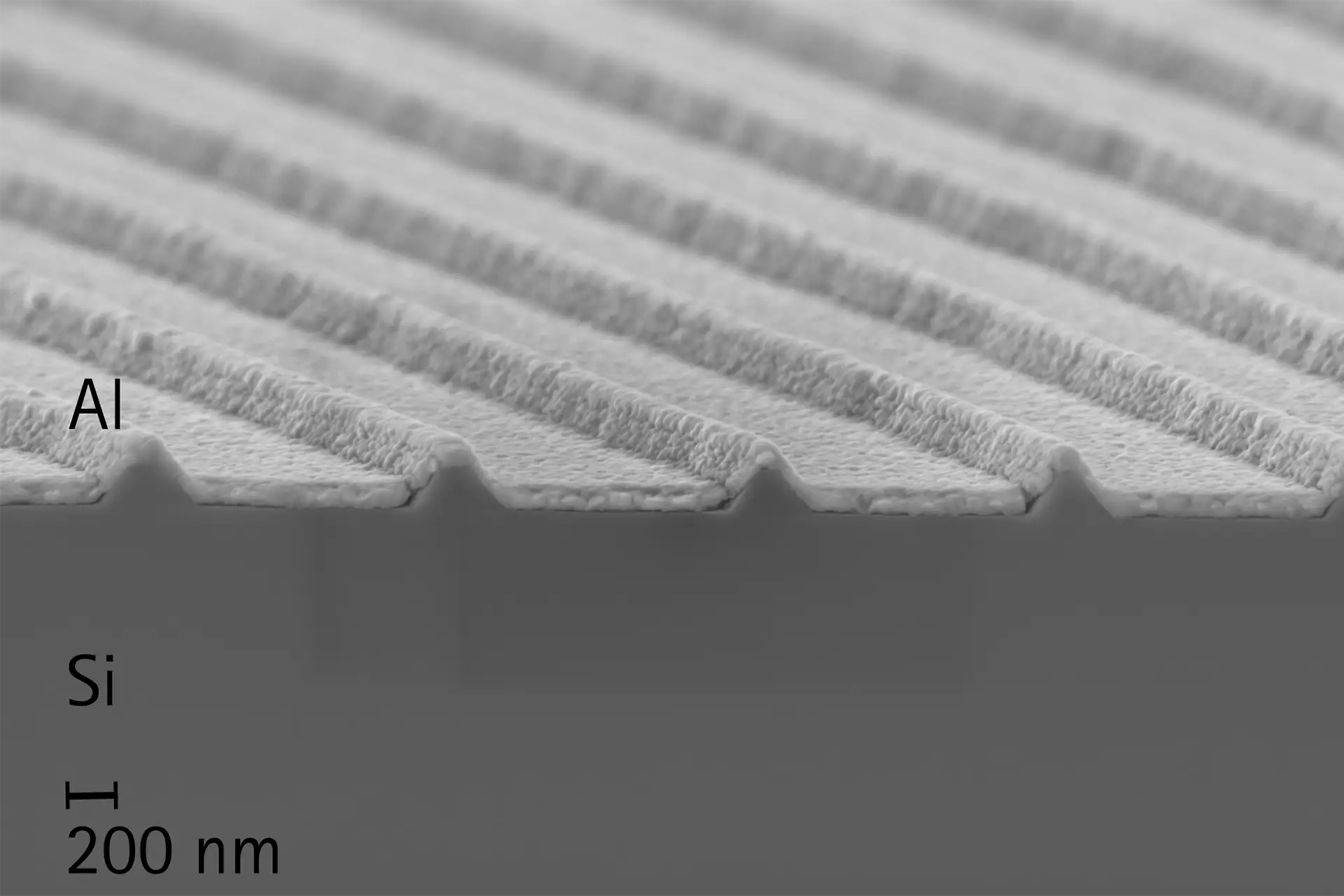

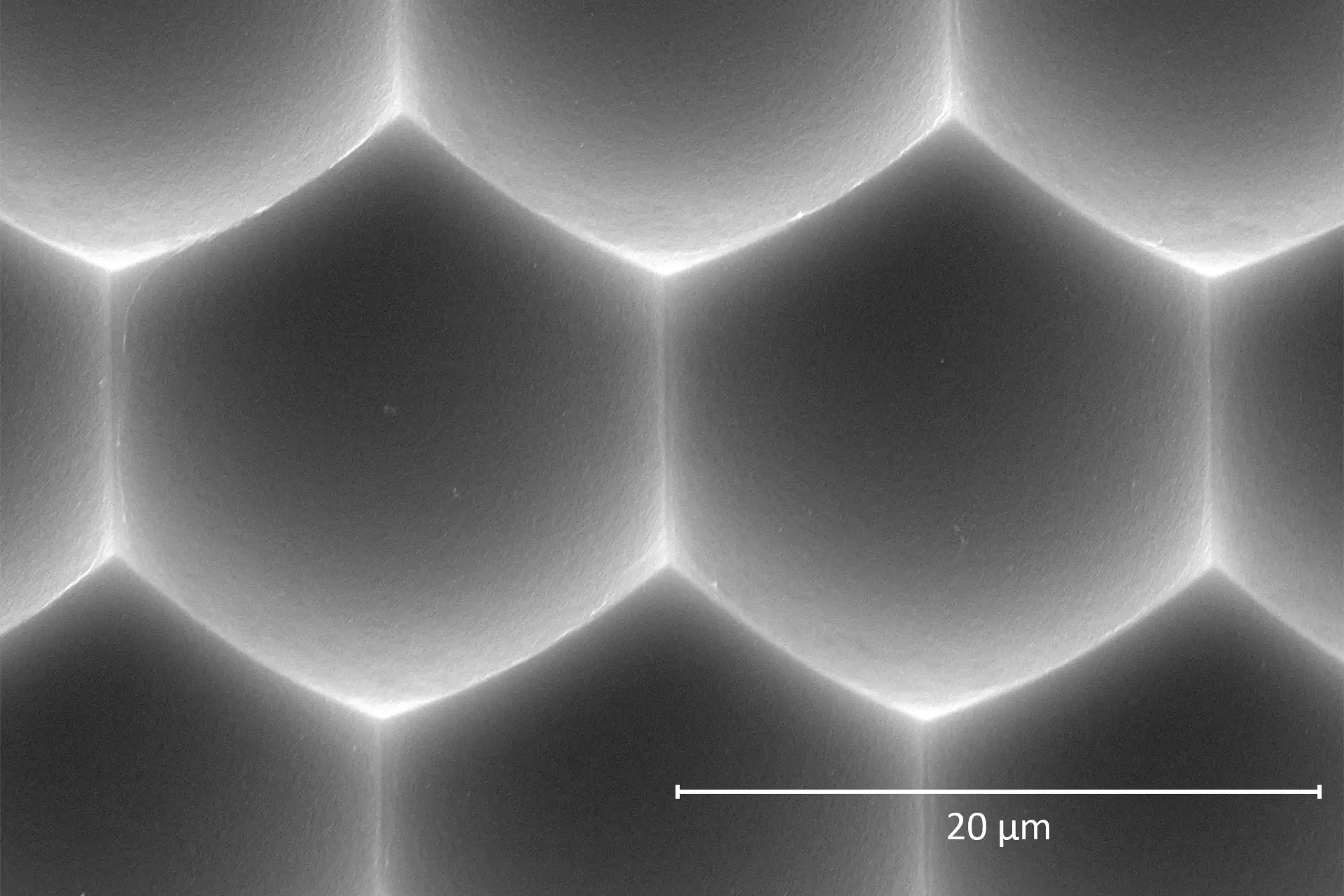

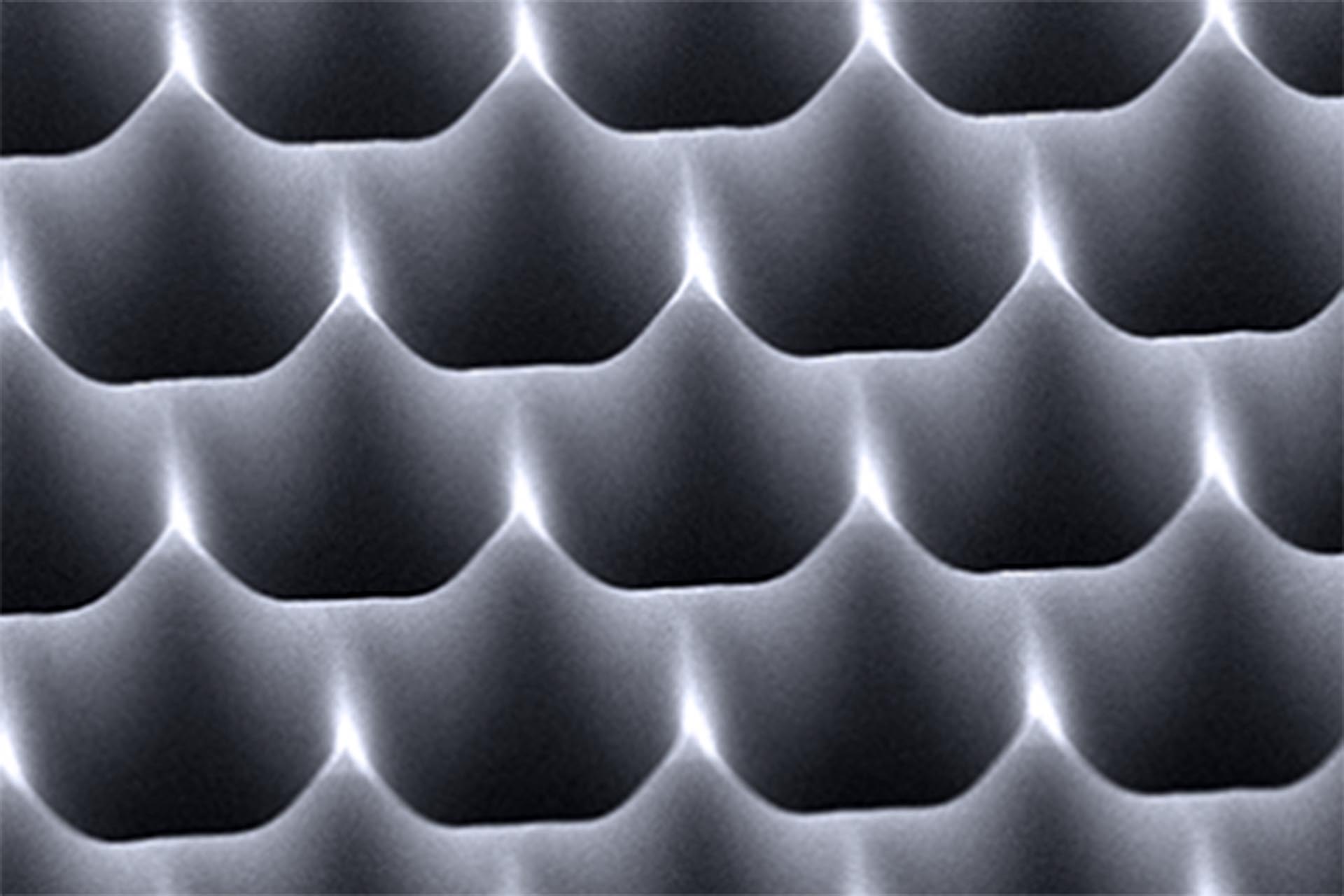

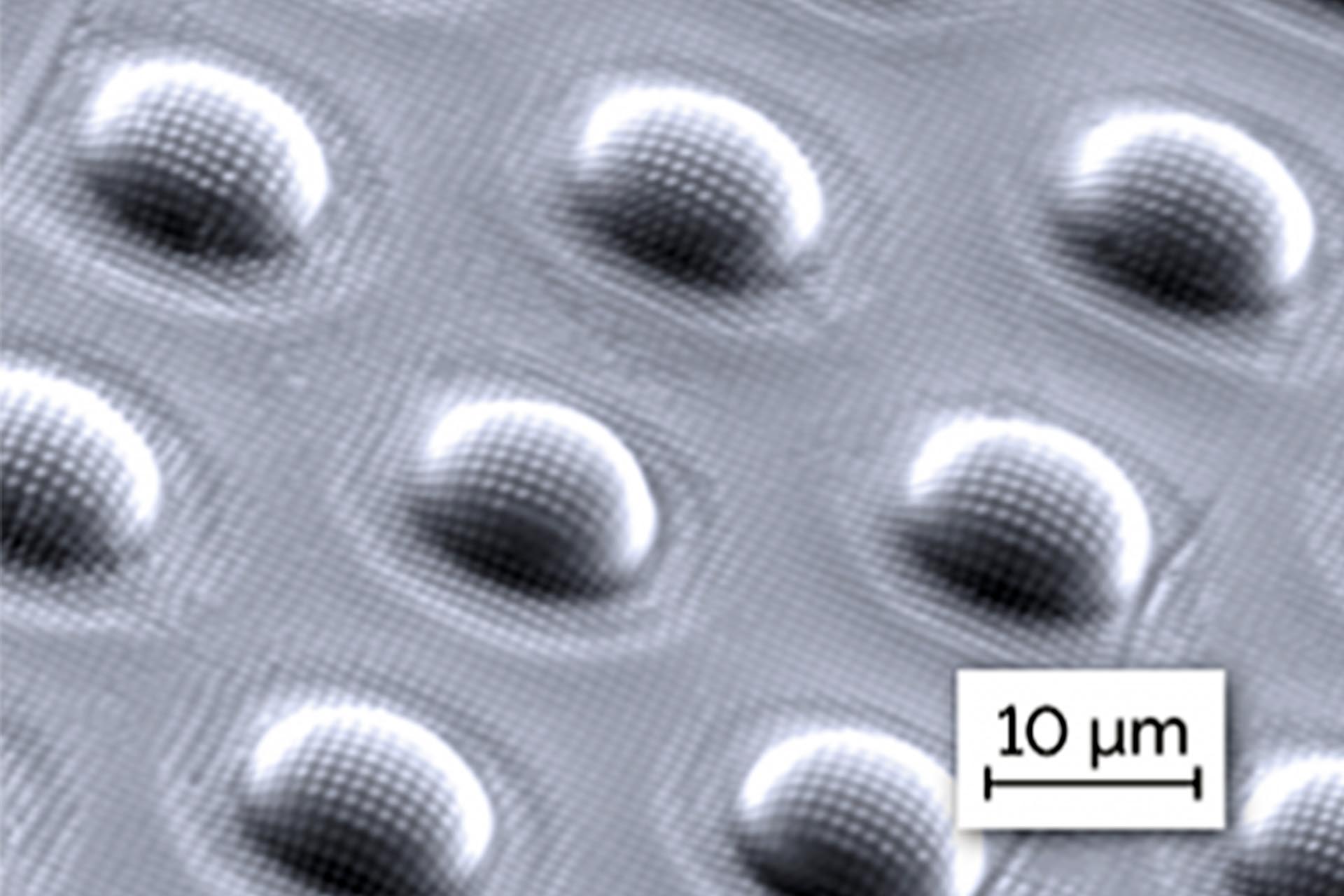

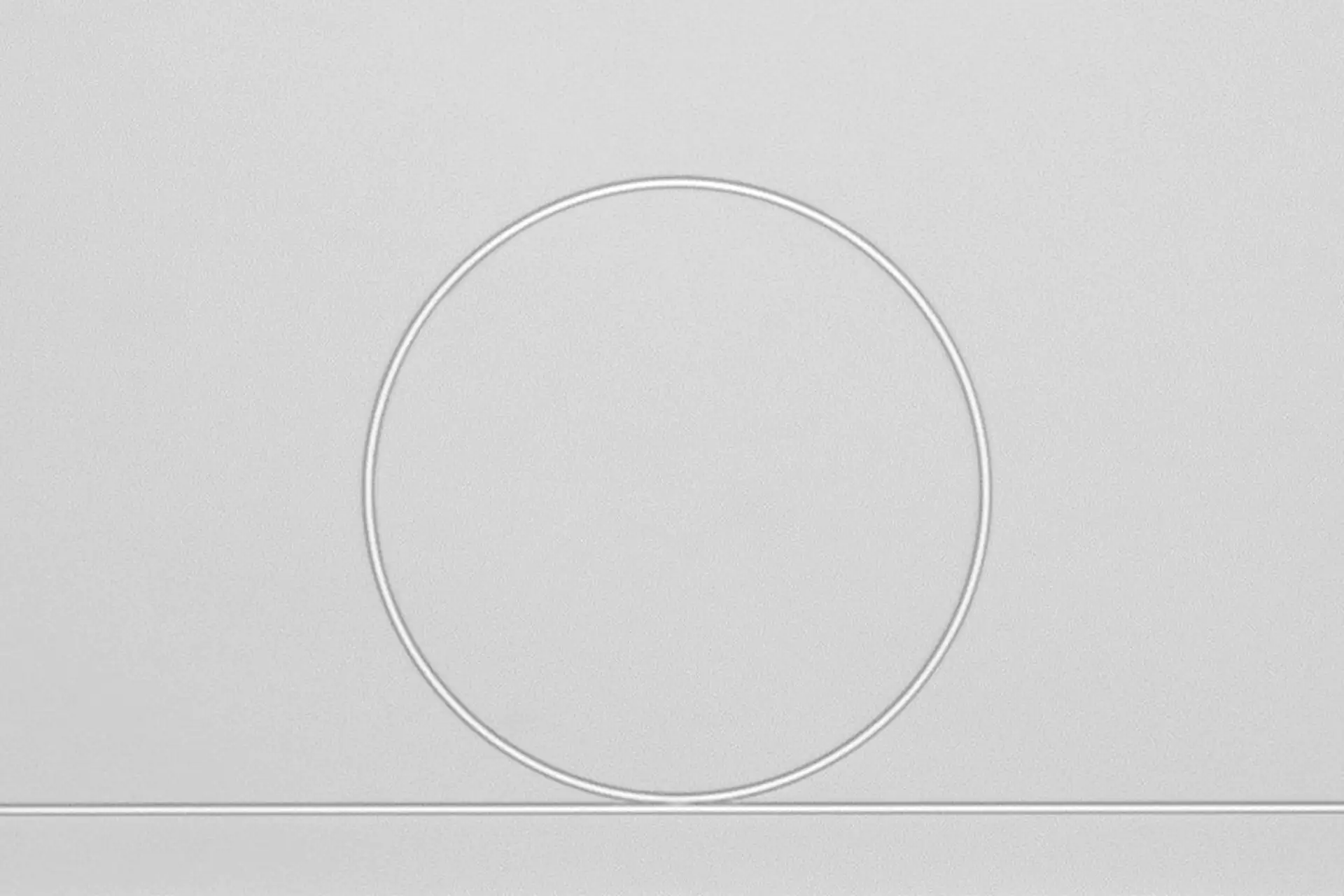

Micro-lens arrays and complex Fresnel lenses are crucial components in compact camera optics due to the increasing demand for advanced and miniaturized optics in smartphones and tablets. These micro-lenses are used in a variety of applications such as wave-front sensors, fiber coupling, or homogenizing light sources. The production of these micro-lenses begins with grayscale lithography to generate a mold, which can then be replicated via LIGA to create a metal shim, used as a master tool for molding, imprinting, or hot embossing. Grayscale lithography is also used to fabricate micro-prisms, waveguides, blazed gratings, CGH (Computer Generated Holograms) and specialty security labels, among others. Direct Write Lithography enables the precise manufacturing of VLS (Variable Line Spacing) and standard gratings. The DWL series includes various high-performance Grayscale lithography systems, such as DWL 66+ for R&D and the DWL 2000 GS/ DWL 4000 GS for high-end requirements.

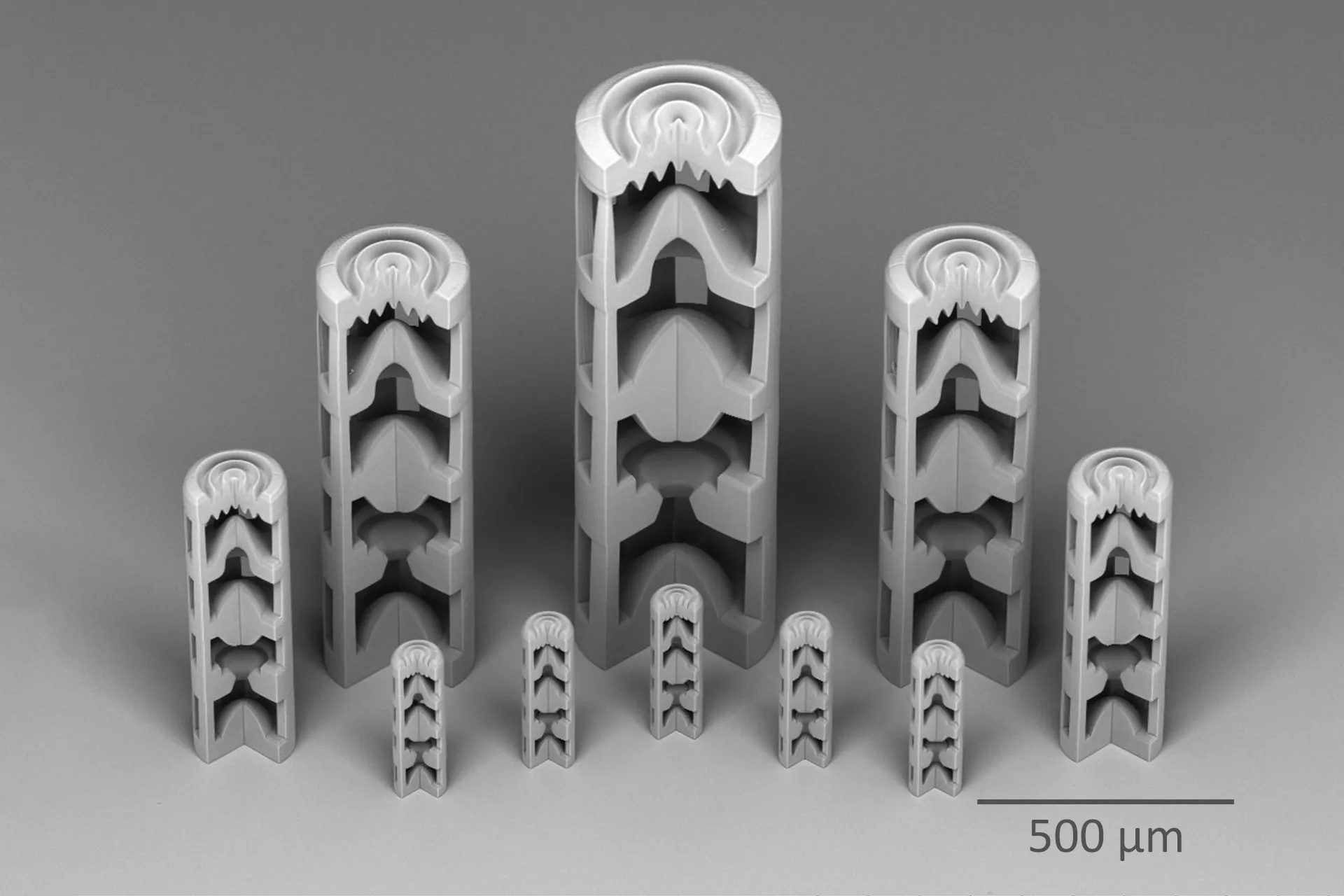

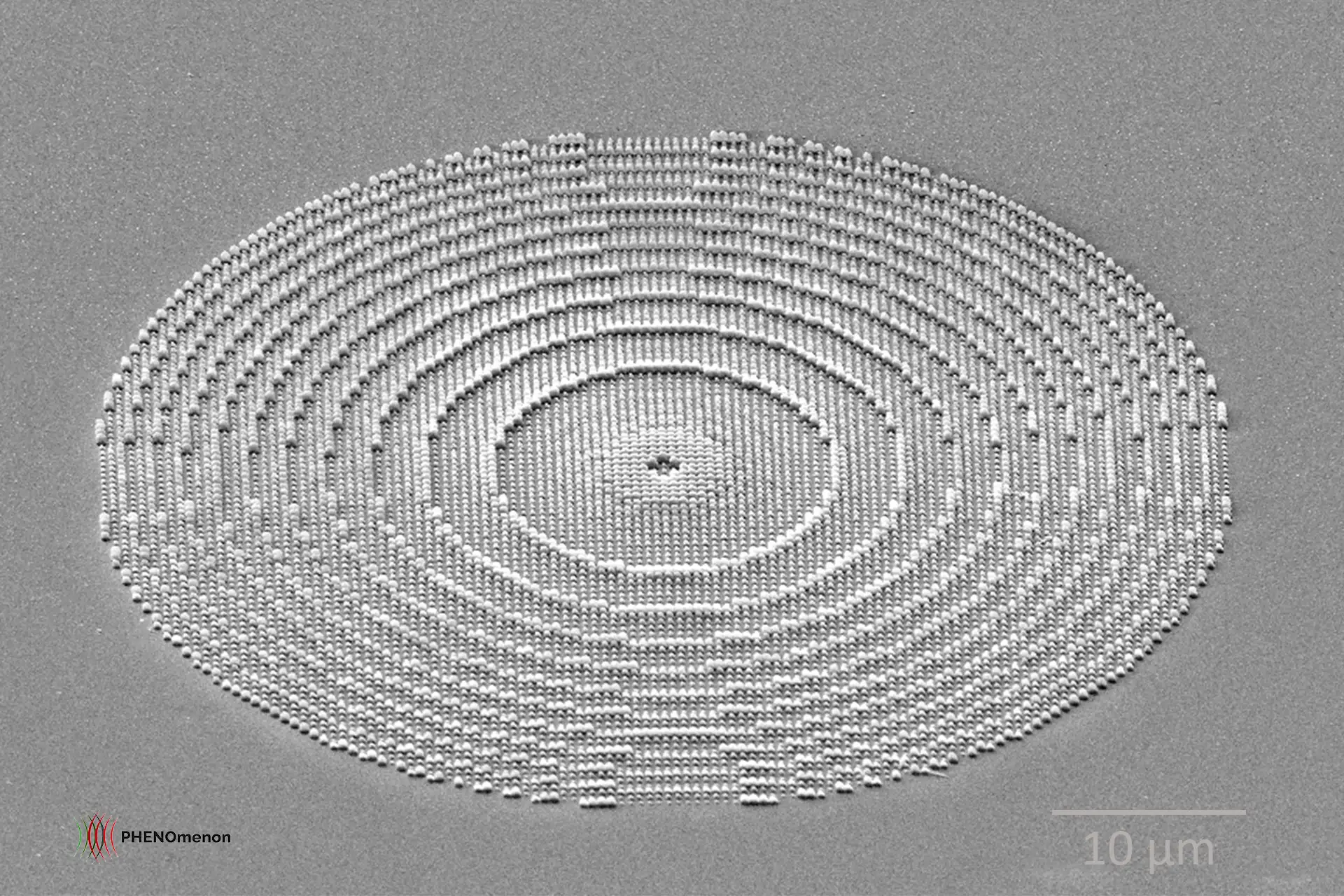

The MPO 100 utilizes Two-Photon Polymerization (TPP) to generate refractive and diffractive micro-optical elements with arbitrary shapes, providing unlimited design freedom compared to conventional techniques. This allows for the creation of miniaturized devices with multiple functions. With the MPO 100, individual micro-lenses or arrays can be fabricated directly on photonic chips, substrates, or optical fibers for endoscopic devices for in- and outcoupling purposes. Additionally, replication masters can be manufactured, providing mass production capabilities of sophisticated optical designs.

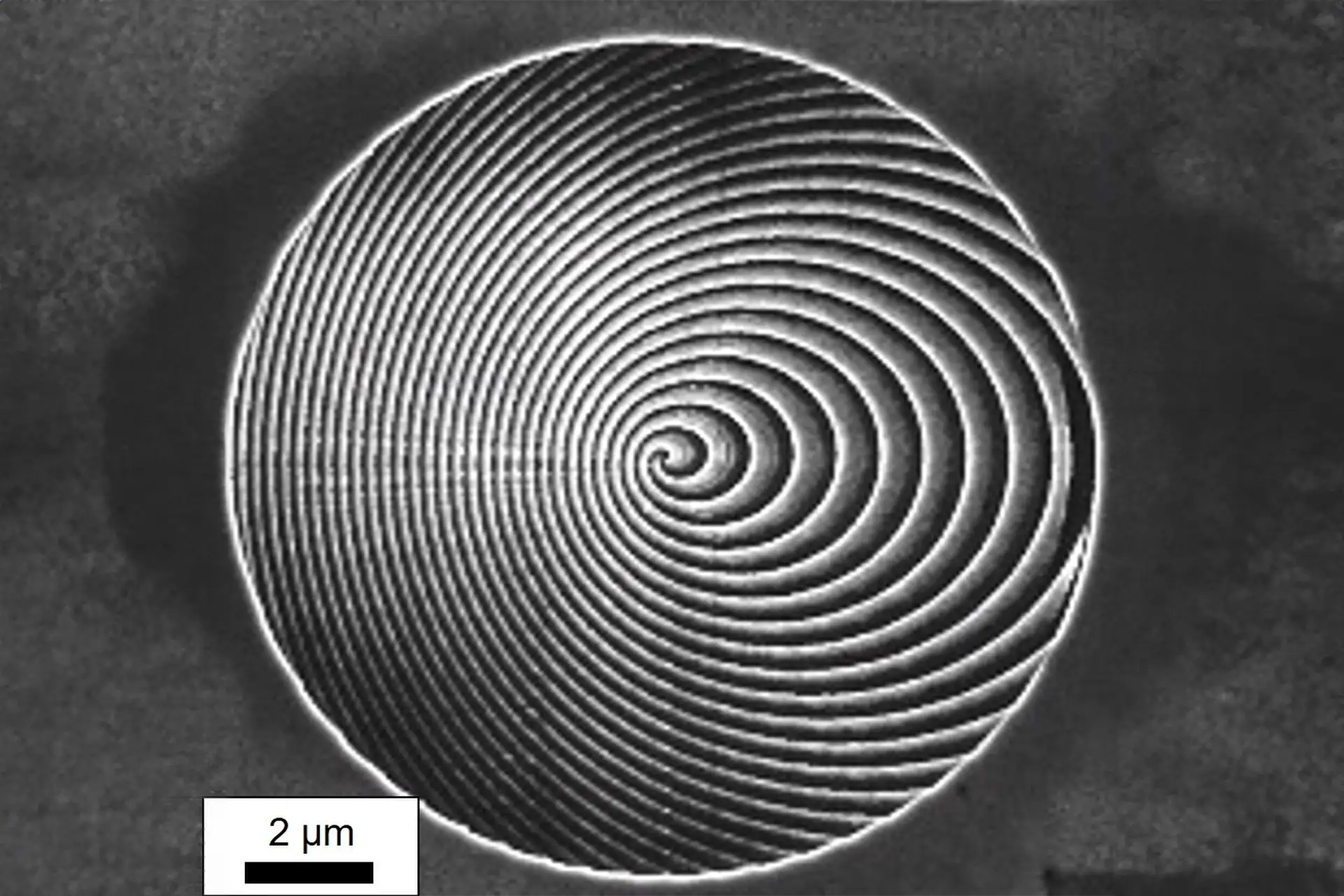

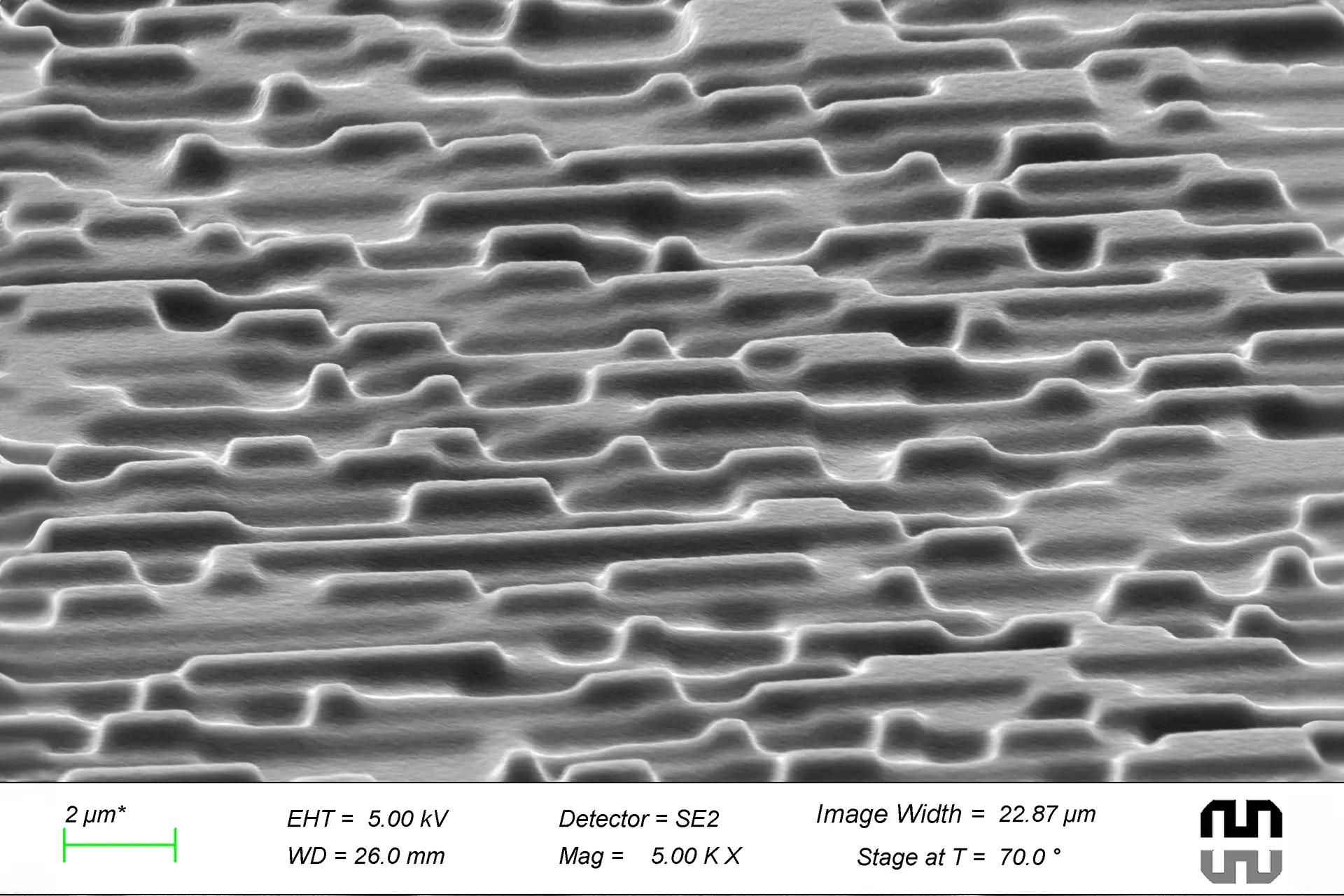

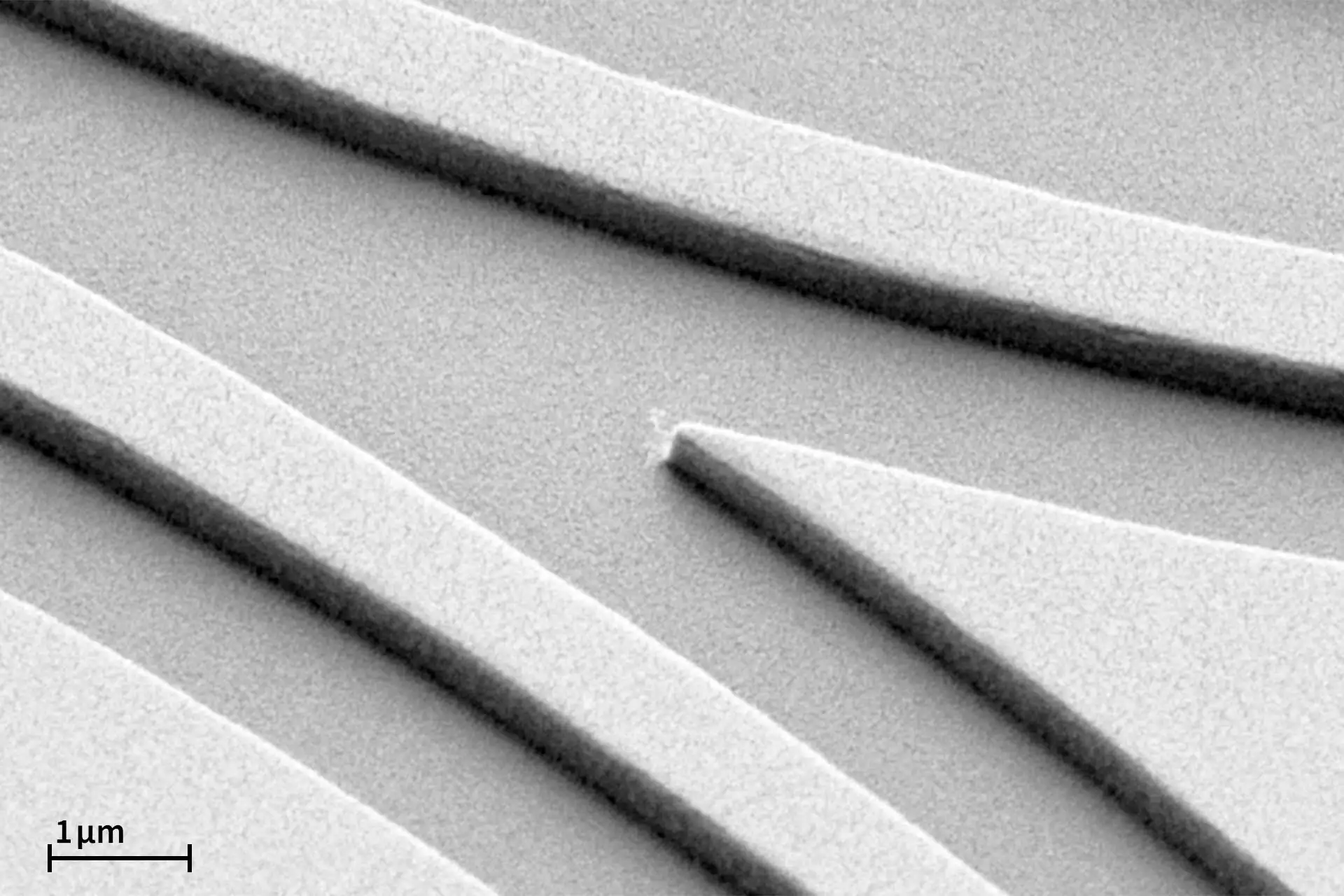

The NanoFrazor systems are powerful tools that can be used for a variety of micro-and nano-optic applications. Their high resolution associated with their grayscale lithography capabilities make them ideal for fabricating nano-optical structures such as diffraction gratings, optical Fourier surfaces, phase plates and more intricate finely tuned optical components.

-

Requirements

-

Very precise shape control

Excellent surface roughness

High throughput

No stitching artefacts

High resolution

Flexible substrate material and sizes for different applications

Diffraction gratings: Strict requirements for surface quality, groove position, and groove profile

-

Solutions

-

High and ultra-high resolution

300 nm (DWL66+), 100 nm (MPO 100), 15 nm (NanoFrazor)Stitching reduction functions

Allowing smooth surfaces of large micro-optical elements in thick photoresistSubstrates from small pieces to G8 panel sizes

Our systems offer the possibility to choose the right stage size for your applicationShape optimization

Used to simplify the compensation of the nonlinear effectsHigh precision stage system for accurate pattern placement

Used to perfectly position micro-optic devicesApplication specific write mode to optimize resolution and throughput

The choice of write modes enables to make the right compromise for your application (DWL series)

Micro-lens arrays and complex Fresnel lenses are crucial components in compact camera optics due to the increasing demand for advanced and miniaturized optics in smartphones and tablets. These micro-lenses are used in a variety of applications such as wave-front sensors, fiber coupling, or homogenizing light sources. The production of these micro-lenses begins with grayscale lithography to generate a mold, which can then be replicated via LIGA to create a metal shim, used as a master tool for molding, imprinting, or hot embossing. Grayscale lithography is also used to fabricate micro-prisms, waveguides, blazed gratings, CGH (Computer Generated Holograms) and specialty security labels, among others. Direct Write Lithography enables the precise manufacturing of VLS (Variable Line Spacing) and standard gratings. The DWL series includes various high-performance Grayscale lithography systems, such as DWL 66+ for R&D and the DWL 2000 GS/ DWL 4000 GS for high-end requirements.

The MPO 100 utilizes Two-Photon Polymerization (TPP) to generate refractive and diffractive micro-optical elements with arbitrary shapes, providing unlimited design freedom compared to conventional techniques. This allows for the creation of miniaturized devices with multiple functions. With the MPO 100, individual micro-lenses or arrays can be fabricated directly on photonic chips, substrates, or optical fibers for endoscopic devices for in- and outcoupling purposes. Additionally, replication masters can be manufactured, providing mass production capabilities of sophisticated optical designs.

The NanoFrazor systems are powerful tools that can be used for a variety of micro-and nano-optic applications. Their high resolution associated with their grayscale lithography capabilities make them ideal for fabricating nano-optical structures such as diffraction gratings, optical Fourier surfaces, phase plates and more intricate finely tuned optical components.

Very precise shape control

Excellent surface roughness

High throughput

No stitching artefacts

High resolution

Flexible substrate material and sizes for different applications

Diffraction gratings: Strict requirements for surface quality, groove position, and groove profile

High and ultra-high resolution

Stitching reduction functions

Substrates from small pieces to G8 panel sizes

Shape optimization

High precision stage system for accurate pattern placement

Application specific write mode to optimize resolution and throughput

Application images

suitable Systems

DWL 2000 GS / DWL 4000 GS

- Direct Write Laser Lithography System

The most advanced industrial grayscale lithography tool on the market.

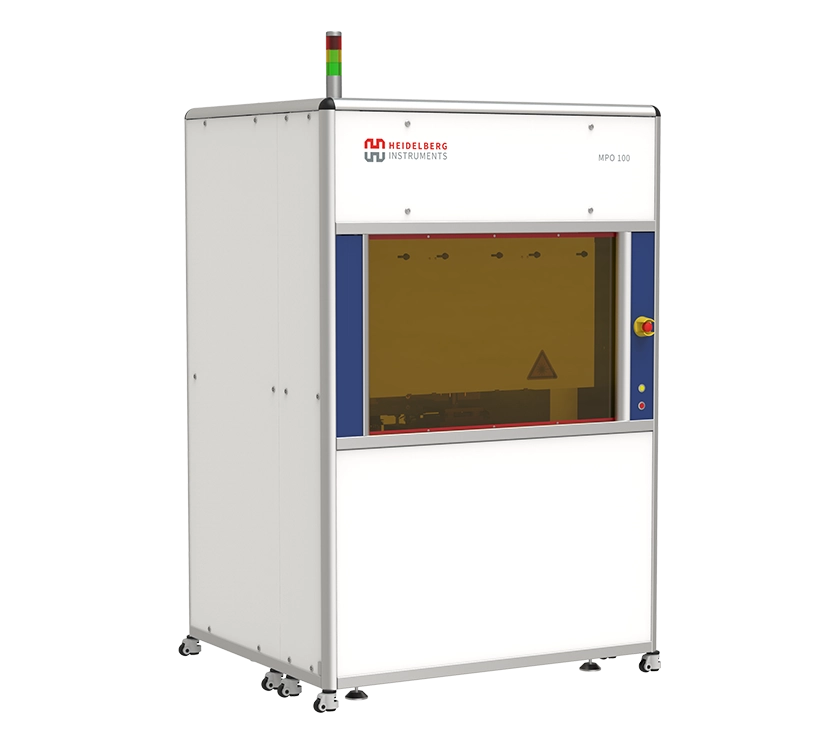

MPO 100

- Two-Photon Polymerization Multi-User Tool

Multi-User Tool for 3D Lithography and 3D Microprinting of microstructures with applications in micro-optics, photonics, micro-mechanics and biomedical engineering.

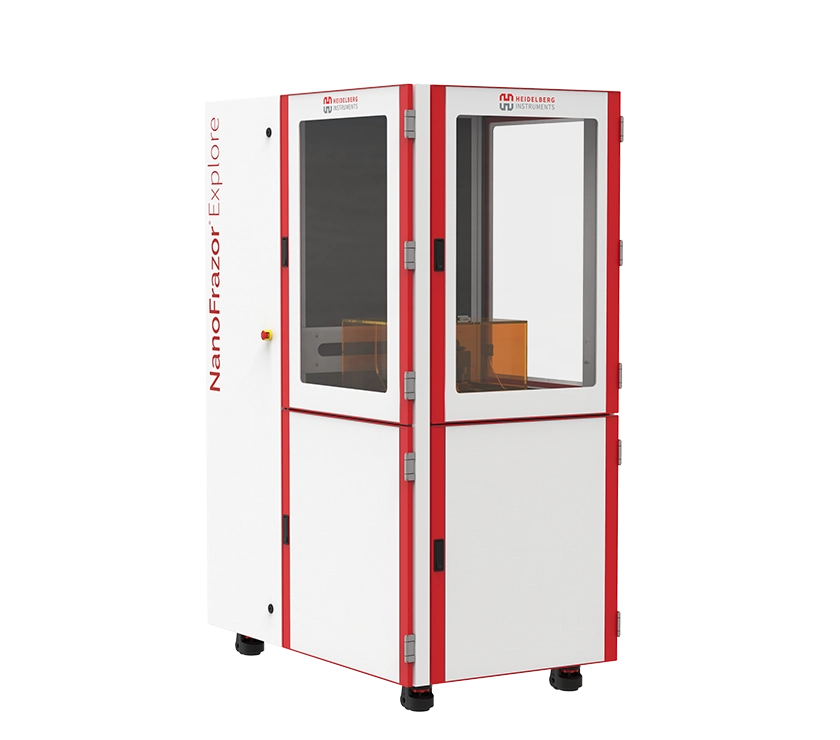

NanoFrazor Explore

- Thermal Scanning Probe Lithography System

Thermal scanning probe lithography tool with direct laser sublimation and grayscale modules. Excellent alternative to e-beam lithography tools.

NanoFrazor Scholar

- Thermal Scanning Probe Lithography System

Table-top thermal scanning probe lithography system with in-situ AFM imaging. Compact and compatible with glovebox.