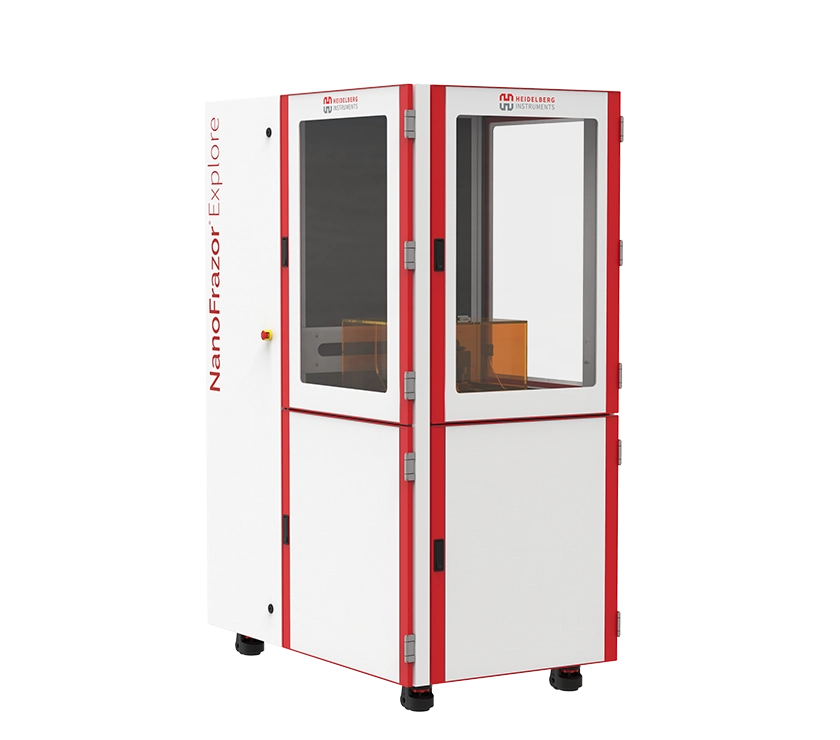

NanoFrazor Explore

- Thermal Scanning Probe Lithography System

Thermal scanning probe lithography tool with direct laser sublimation and grayscale modules. Excellent alternative to e-beam lithography tools.

Description

Conventional lithography processes require wet development of the resist before the written features can be inspected and measured.

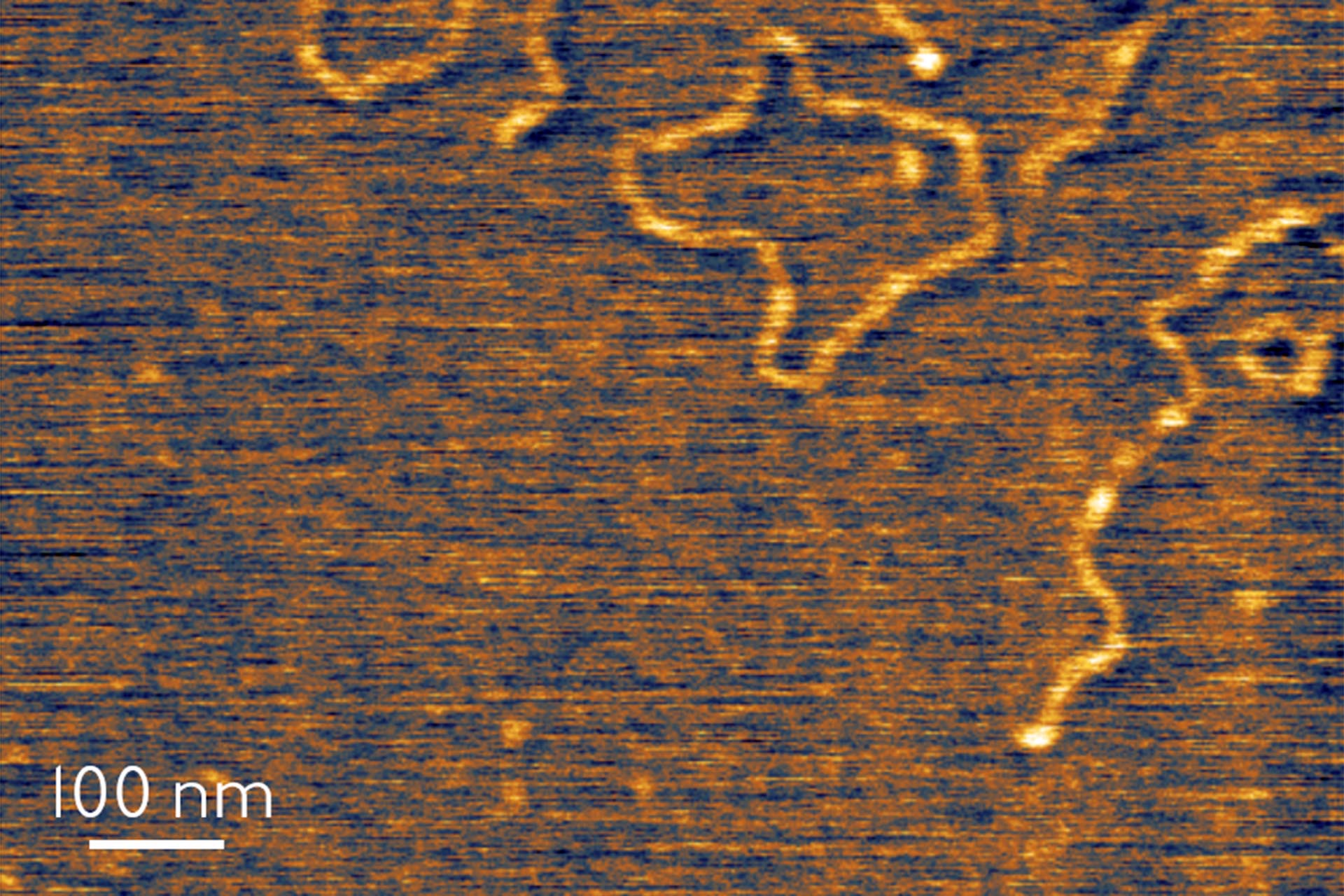

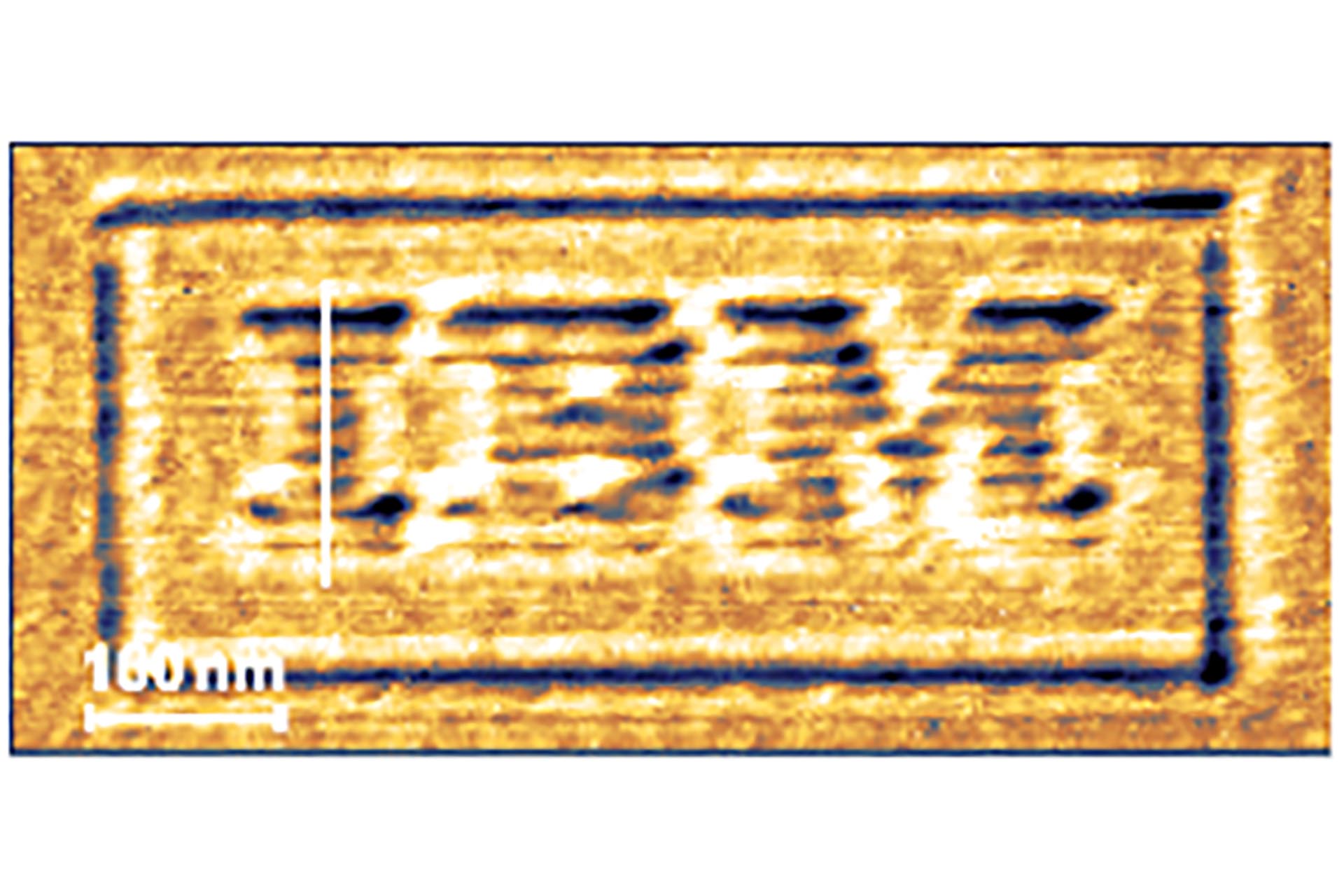

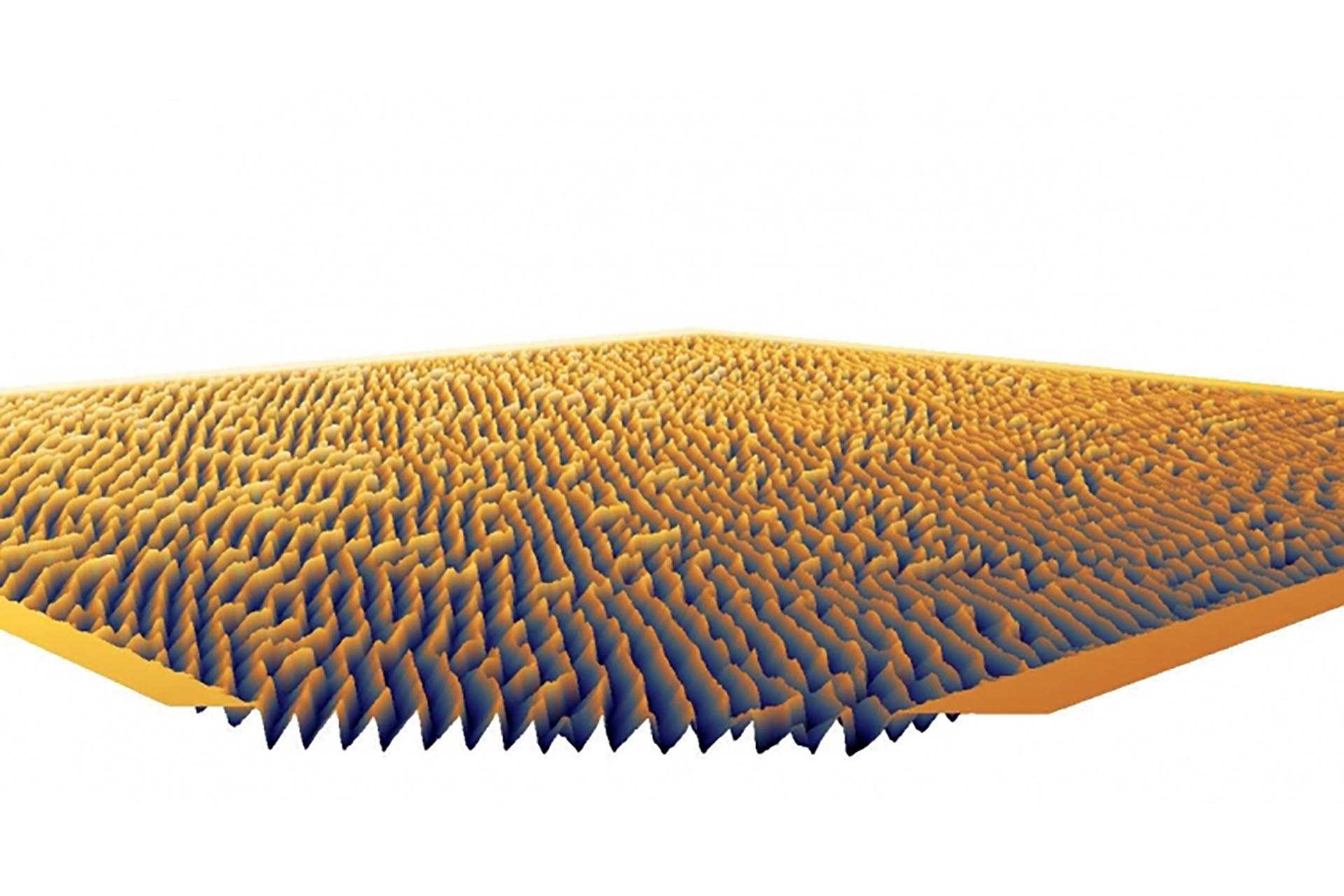

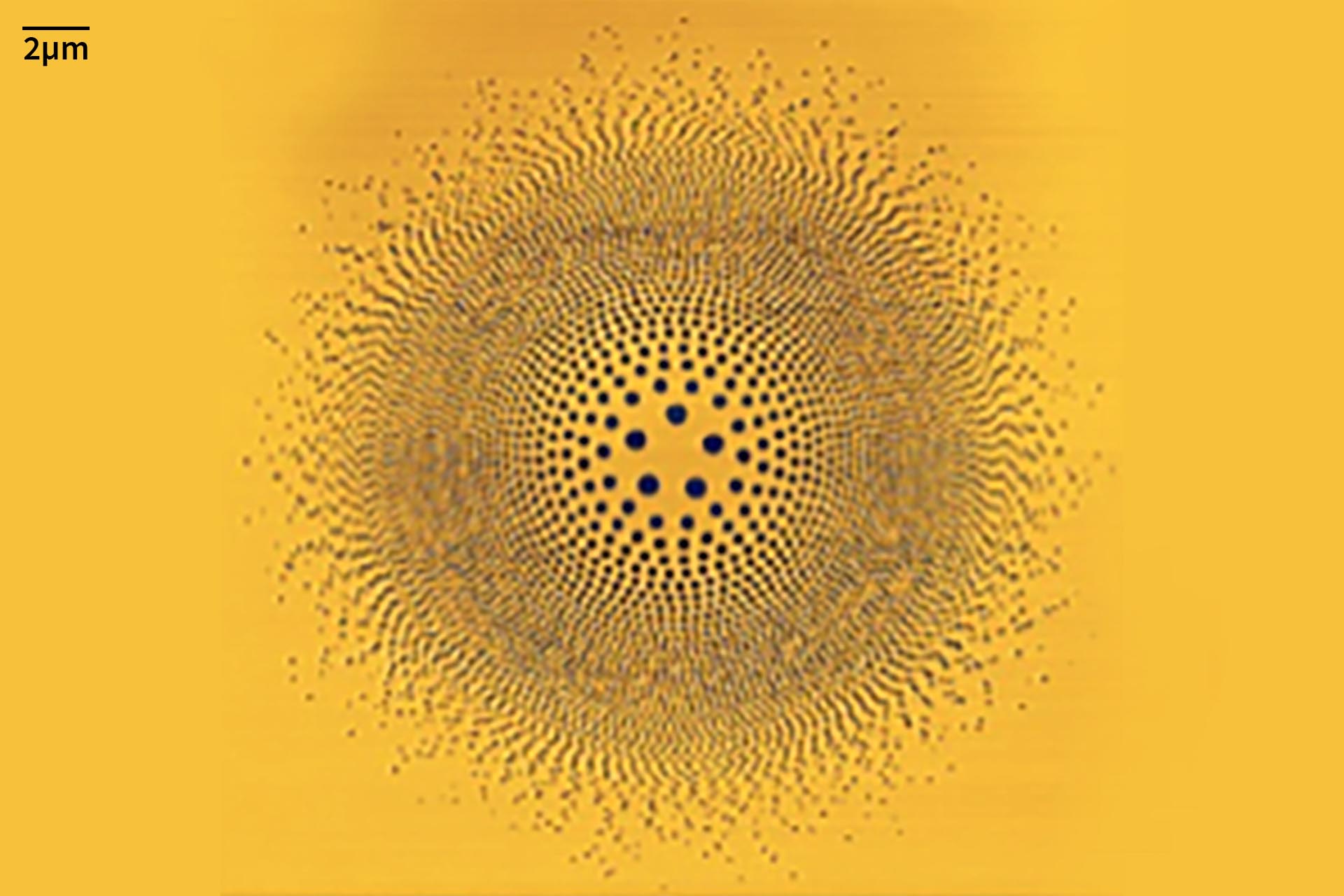

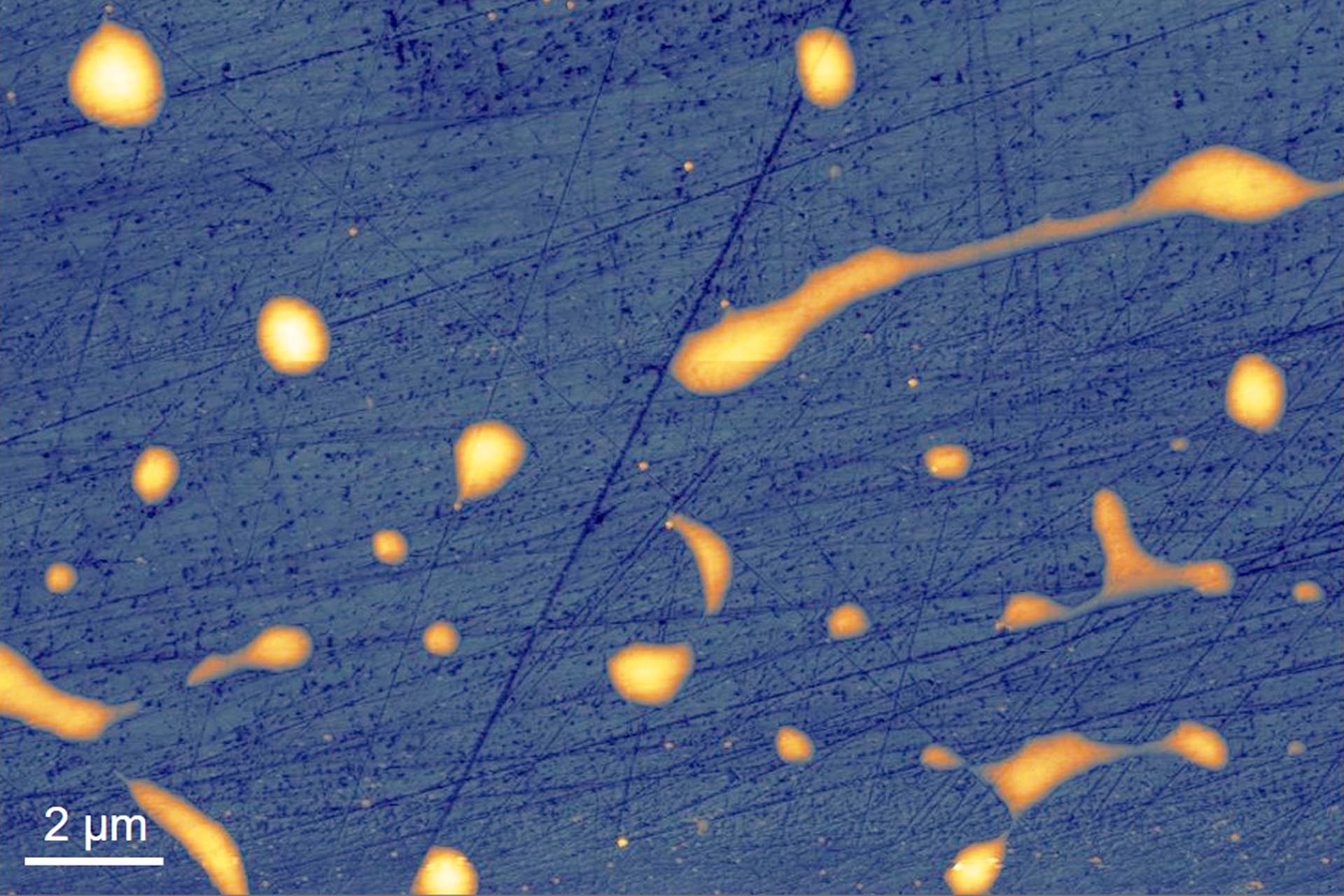

Direct-write lithography processes such as NanoFrazor lithography and low-throughput laser writing directly sublimate thermal resists like PPA. This direct removal of resist enables immediate inspection and metrology of the written features, which is beneficial for process development and rapid turnaround fabrication. Furthermore, it allows the NanoFrazor tools to achieve and maintain extremely high patterning quality by the patented “Closed-Loop Lithography” approach.

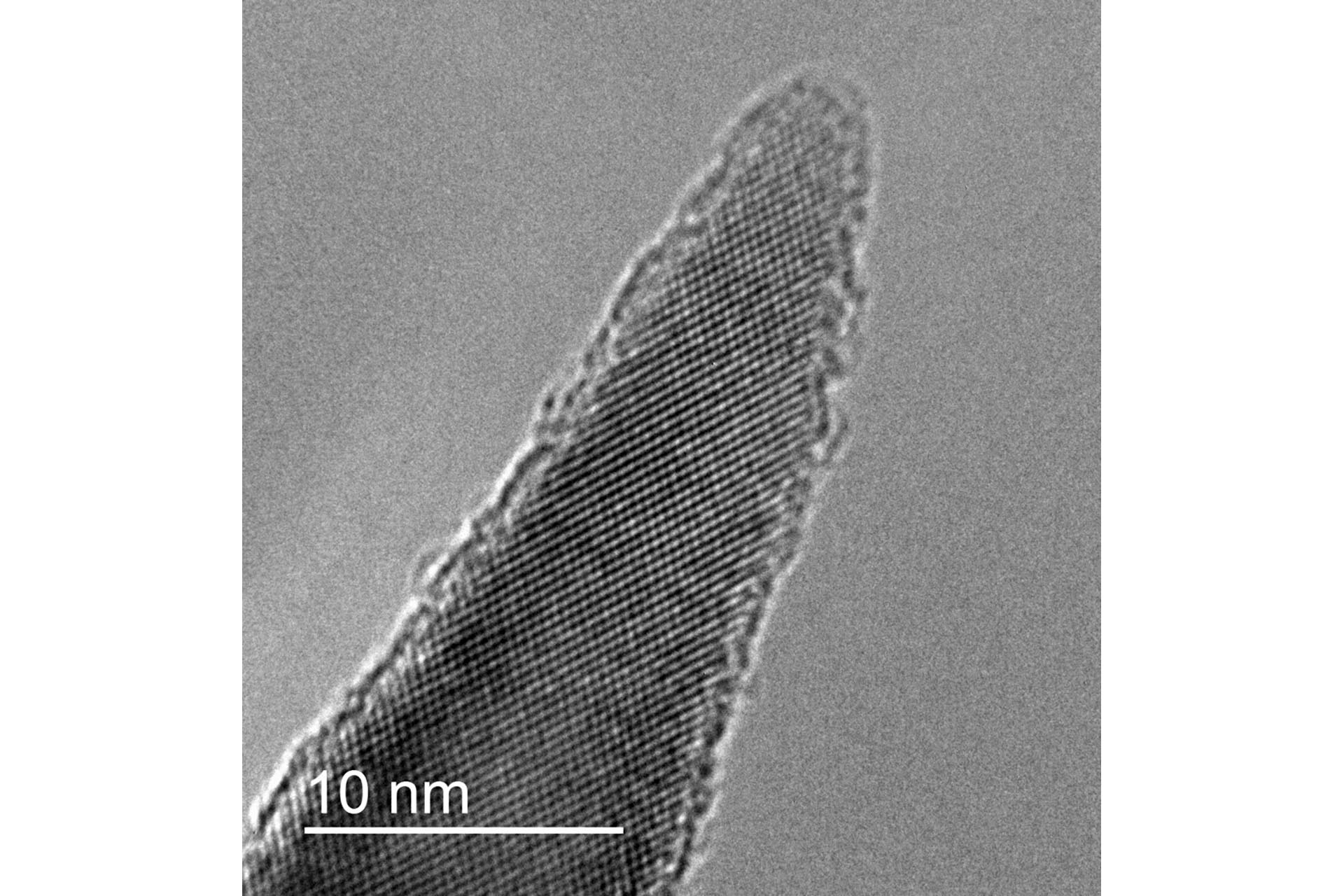

The NanoFrazor systems use the same tip that is used for patterning for in-situ inspection of the written structures. Topography is imaged by means of a special metrology technique, which originates from the discovery of the Nobel Prize winner Gerd Binnig that the electrical resistance of the IBM Millipede cantilevers was strongly distance-dependent. This discovery enabled the easy-to-use and reliable NanoFrazor distance sensing method, enabling fast imaging and accurate metrology of high-resolution, shallow topographies in soft surfaces (like resist coatings).

Conventional lithography processes require wet development of the resist before the written features can be inspected and measured.

Direct-write lithography processes such as NanoFrazor lithography and low-throughput laser writing directly sublimate thermal resists like PPA. This direct removal of resist enables immediate inspection and metrology of the written features, which is beneficial for process development and rapid turnaround fabrication. Furthermore, it allows the NanoFrazor tools to achieve and maintain extremely high patterning quality by the patented “Closed-Loop Lithography” approach.

The NanoFrazor systems use the same tip that is used for patterning for in-situ inspection of the written structures. Topography is imaged by means of a special metrology technique, which originates from the discovery of the Nobel Prize winner Gerd Binnig that the electrical resistance of the IBM Millipede cantilevers was strongly distance-dependent. This discovery enabled the easy-to-use and reliable NanoFrazor distance sensing method, enabling fast imaging and accurate metrology of high-resolution, shallow topographies in soft surfaces (like resist coatings).

Thermal scanning probe lithography tool with direct laser sublimation and grayscale modules. Excellent alternative to e-beam lithography tools.

Table-top thermal scanning probe lithography system with in-situ AFM imaging. Compact and compatible with glovebox.

We are always at your disposal.

Please send us your request.

To view the form, please enable Marketing cookies.

Subscribe to our newsletter

to receive the newest information.

To view the form, please enable Marketing cookies.