Semiconductors

Unlocking the future: Empowering Semiconductor innovations with Heidelberg Instruments' precision lithography tools

-

Description

-

Semiconductors are characterized by their ability to vary their electrical conductivity when exposed to external factors like voltage, heat, or light. They serve as a foundation for electronic devices in modern technology. Semiconductor devices are constructed on wafers composed of a variety of materials. Some wafers consist of a single element, such as silicon, while others incorporate a blend of elements, forming complex crystalline structures with unique electronic properties, as seen in compound semiconductors.

Photolithography is a pivotal process in semiconductor manufacturing that utilizes masks or direct writing techniques to transfer precise patterns onto wafers. It plays a crucial role in defining the intricate structures that form the basis of integrated circuits and other semiconductor devices.

Heidelberg Instruments offers tools that are suited to several critical processes during the fabrication of semiconductor-based devices, from reticles demanding high precision and high uniformity to high-throughput maskless exposures with adaptive patterning. These laser lithography tools offer versatility by enabling direct writing on photoresist-coated surfaces, facilitating rapid prototyping and customization. Their precision in alignment supports multi-layer device production and can correct for individual die misalignment and deformation. This also makes them suitable for semiconductor packaging.

-

Requirements

-

High-quality resists

High uniformity and consistency

High throughput

Compatibility with existing processes

Alignment and overlay accuracy

-

Solutions

-

Laser with excellent TEM00 qualified

for typical semiconductors resists (ULTRA & VPG+)Environmental control:

metrology system with self-calibrationInterferometric position measurement:

real-time stage map correction2nd layer alignment < 100 nm

(ULTRA)Warped substrate handling

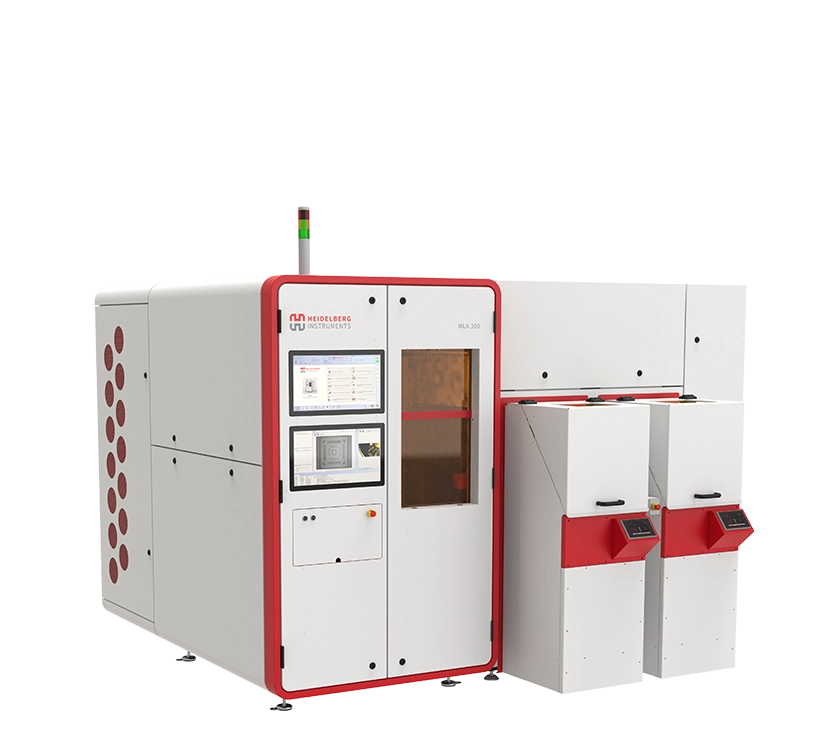

(MLA 300)

Semiconductors are characterized by their ability to vary their electrical conductivity when exposed to external factors like voltage, heat, or light. They serve as a foundation for electronic devices in modern technology. Semiconductor devices are constructed on wafers composed of a variety of materials. Some wafers consist of a single element, such as silicon, while others incorporate a blend of elements, forming complex crystalline structures with unique electronic properties, as seen in compound semiconductors.

Photolithography is a pivotal process in semiconductor manufacturing that utilizes masks or direct writing techniques to transfer precise patterns onto wafers. It plays a crucial role in defining the intricate structures that form the basis of integrated circuits and other semiconductor devices.

Heidelberg Instruments offers tools that are suited to several critical processes during the fabrication of semiconductor-based devices, from reticles demanding high precision and high uniformity to high-throughput maskless exposures with adaptive patterning. These laser lithography tools offer versatility by enabling direct writing on photoresist-coated surfaces, facilitating rapid prototyping and customization. Their precision in alignment supports multi-layer device production and can correct for individual die misalignment and deformation. This also makes them suitable for semiconductor packaging.

High-quality resists

High uniformity and consistency

High throughput

Compatibility with existing processes

Alignment and overlay accuracy

Laser with excellent TEM00 qualified

Environmental control:

Interferometric position measurement:

2nd layer alignment < 100 nm

Warped substrate handling

Application images

suitable Systems

VPG+ 200 / VPG+ 400

- Volume Pattern Generator

A production tool for standard photomasks and microstructures in i-line resists.

VPG+ 800 / VPG+ 1400

- Volume Pattern Generator

Photomask production on large substrates, perfect for display applications.

VPG 300 DI

- Maskless Stepper

Maskless direct imager for high-accuracy and high-resolution microstructures.

ULTRA

- Laser Mask Writer

A tool specifically designed to produce mature semiconductor photomasks.