Displays

Revolutionizing Display Production: Heidelberg Instruments' Tools at the Forefront of Precision in Pixel Arrangement and Optical Innovation

-

Description

-

Displays represent a fundamental component in modern electronics, providing visual interfaces for a wide range of devices, from smartphones to large-scale flat-panel displays (FPD). Display technologies depend on materials with diverse electrical conductivity, like ITO. These materials are layered onto substrates, forming the basis for pixelated displays. Utilizing photolithography, intricate patterns are transferred into these materials using masks or direct writing techniques.

Heidelberg Instruments tools are utilized in multiple stages of display production, including the precise and uniform patterning of large photomasks, up to 1400 x 1400 mm² (VPG+ 1400), used for insulating and conducting layers prior to integrating liquid crystals or organic compounds (in LCDs and OLEDs). They succeed in generating highly uniform color-filtering arrays. They also find application in the fabrication of backlight illumination panels, in 2.5D micro-structures like diffusers or micro-lens arrays (DWL 2000 GS / DWL 4000 GS), and in the packaging process for integration into electronic devices (MLA 300).

-

Requirements

-

Minimized Mura

High uniformity and consistency

High throughput

Large area

-

Solutions

-

Laser with excellent TEM00

qualified for typical semiconductor resists (ULTRA & VPG+)Interferometric position measurement

Real time stage map correction, with a resolution down to 1.2 nm (ULTRA & VPG+)Fast large-area patterning

1400 x 1400 mm² in less than four hours (VPG+ 1400)Mura minimized

through multiple control functions: Pitch optimization, dual exposure mode, soft-stitching

Displays represent a fundamental component in modern electronics, providing visual interfaces for a wide range of devices, from smartphones to large-scale flat-panel displays (FPD). Display technologies depend on materials with diverse electrical conductivity, like ITO. These materials are layered onto substrates, forming the basis for pixelated displays. Utilizing photolithography, intricate patterns are transferred into these materials using masks or direct writing techniques.

Heidelberg Instruments tools are utilized in multiple stages of display production, including the precise and uniform patterning of large photomasks, up to 1400 x 1400 mm² (VPG+ 1400), used for insulating and conducting layers prior to integrating liquid crystals or organic compounds (in LCDs and OLEDs). They succeed in generating highly uniform color-filtering arrays. They also find application in the fabrication of backlight illumination panels, in 2.5D micro-structures like diffusers or micro-lens arrays (DWL 2000 GS / DWL 4000 GS), and in the packaging process for integration into electronic devices (MLA 300).

Minimized Mura

High uniformity and consistency

High throughput

Large area

Laser with excellent TEM00

Interferometric position measurement

Fast large-area patterning

Mura minimized

Application images

suitable Systems

VPG+ 200 / VPG+ 400

- Volume Pattern Generator

A production tool for standard photomasks and microstructures in i-line resists.

VPG 300 DI

- Maskless Stepper

Maskless direct imager for high-accuracy and high-resolution microstructures.

ULTRA

- Laser Mask Writer

A tool specifically designed to produce mature semiconductor photomasks.

DWL 2000 GS / DWL 4000 GS

- Direct Write Laser Lithography System

The most advanced industrial grayscale lithography tool on the market.

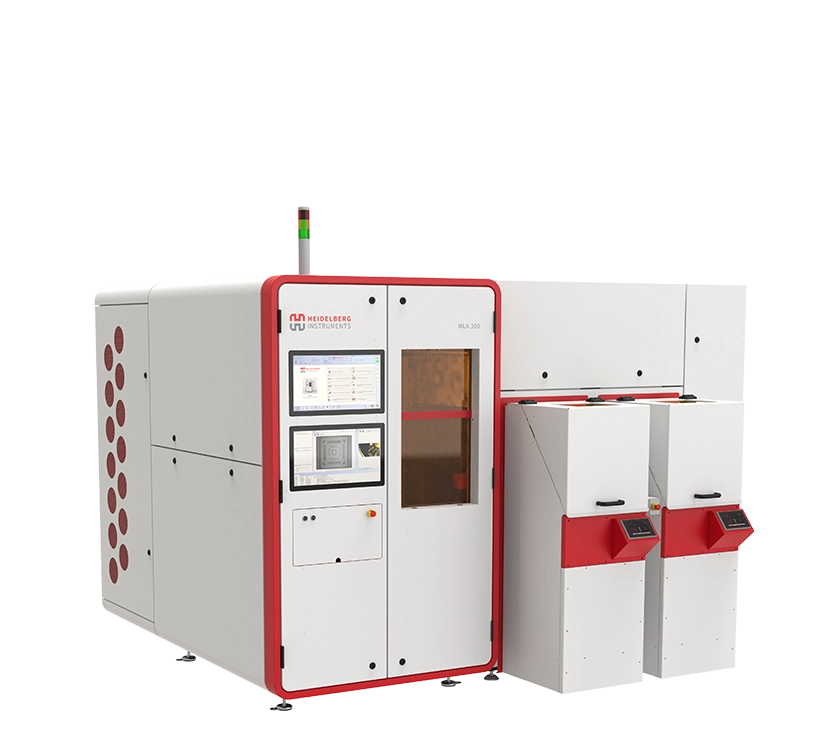

MLA 300

- Maskless Aligner

Optimized for industrial production with highest throughput and seamless integration into industrial production lines.