NanoFrazor Scholar

- Thermal Scanning Probe Lithography System

Table-top thermal scanning probe lithography system with in-situ AFM imaging. Compact and compatible with glovebox.

Description

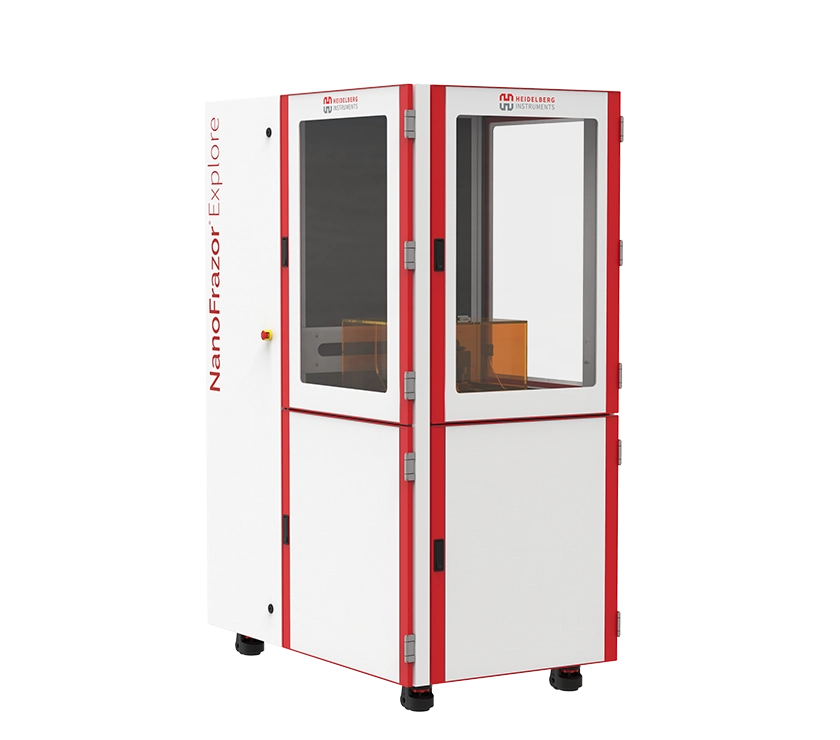

Micro- and nanostructures play a vital role in nano- and biotechnology applications, facilitating the precise handling of small liquid volumes. These applications encompass DNA sequencing, micro- and nanoparticle sorting, assembly, and manipulation of proteins, enzymes, and viruses. Micro- and nanofluidic structures exhibit features like constrictions, sloped floors, and walls and can be patterned with excellent shape control by several Heidelberg Instruments systems, for example the NanoFrazor Scholar and Explore (well suited for nanofluidics).

Materials used are not limited to conventional semiconductor materials; biocompatible polymers and epoxies are also employed.

Direct laser writers such as the DWL 66+, with its grayscale capability, can be used, for example, to form 2.5D topographies guiding neuronal outgrowth. The ability to manipulate and direct axonal pathfinding is crucial for bioengineering.

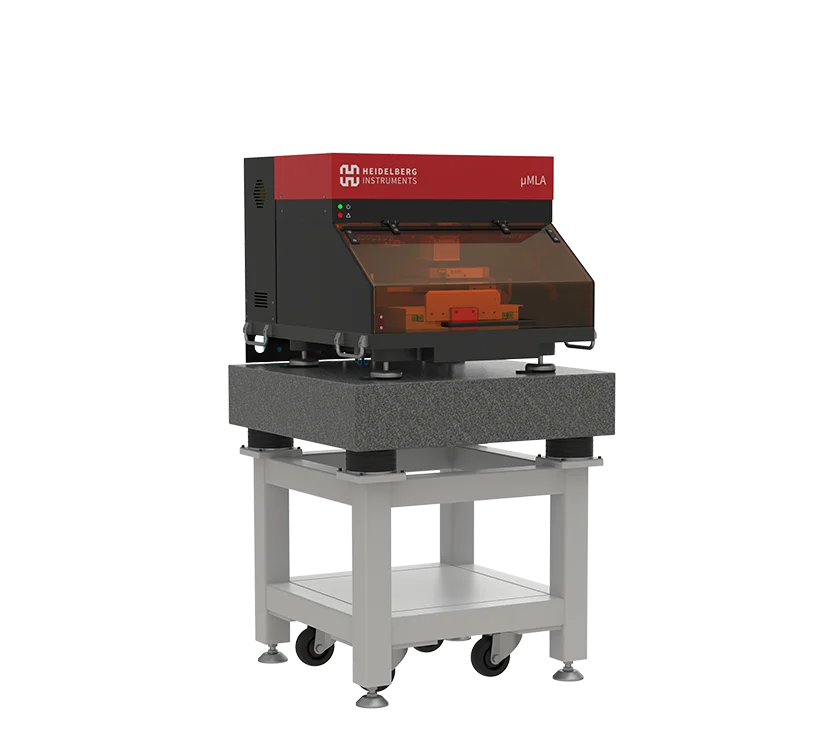

Maskless aligners like the µMLA or the MLA 150 are ideal for SU-8 and high aspect ratio structures that are needed in some biological and medical applications. Some advanced microcontainers have been fabricated with this technology. They enable precise drug delivery to the desired location within the body.

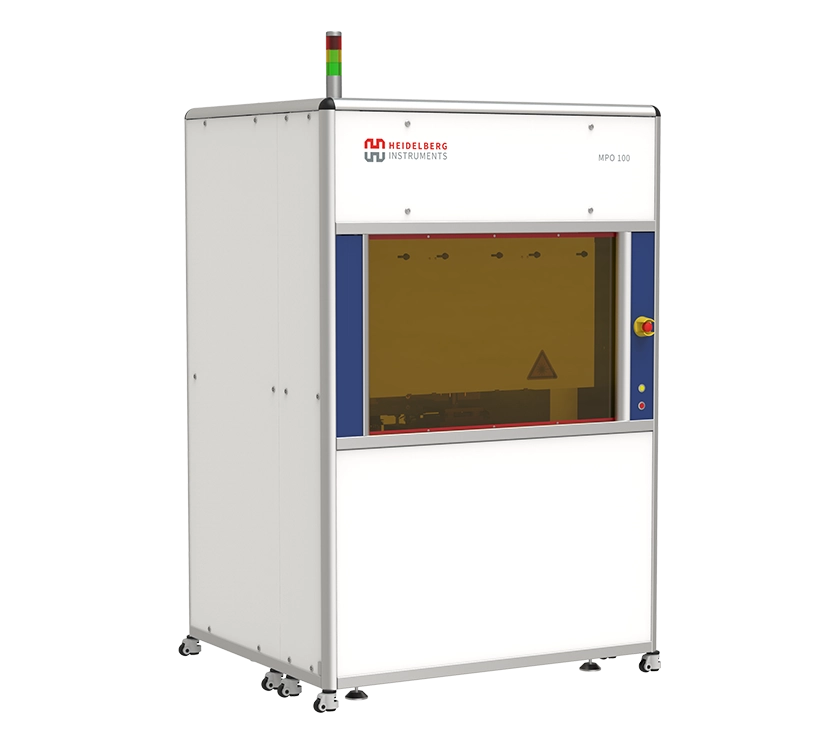

The MPO 100 enables 3D microprinting in various materials, some of which are biocompatible or biodegradable. Those can be used in tissue engineering to print scaffolds on which stem cells could grow to reconstruct organs. Advanced scaffolds like biphasic structures can be fabricated, fostering the regeneration of both cartilage and bone.

High-quality printed structures have found valuable applications in the medical field, and one such application is endoscopy. Optical fibers, with a diameter smaller than 0.5 mm, play a crucial role in endoscopy by providing quasi-noninvasive imaging of tissues. To enhance this technology, lenses can be 3D printed and attached to the end of optical fibers. Moreover, even phase delays and imperfections can be effectively addressed through phase correction techniques, particularly when employing multicore lenses.

Requirements

Solutions

Micro- and nanostructures play a vital role in nano- and biotechnology applications, facilitating the precise handling of small liquid volumes. These applications encompass DNA sequencing, micro- and nanoparticle sorting, assembly, and manipulation of proteins, enzymes, and viruses. Micro- and nanofluidic structures exhibit features like constrictions, sloped floors, and walls and can be patterned with excellent shape control by several Heidelberg Instruments systems, for example the NanoFrazor Scholar and Explore (well suited for nanofluidics).

Materials used are not limited to conventional semiconductor materials; biocompatible polymers and epoxies are also employed.

Direct laser writers such as the DWL 66+, with its grayscale capability, can be used, for example, to form 2.5D topographies guiding neuronal outgrowth. The ability to manipulate and direct axonal pathfinding is crucial for bioengineering.

Maskless aligners like the µMLA or the MLA 150 are ideal for SU-8 and high aspect ratio structures that are needed in some biological and medical applications. Some advanced microcontainers have been fabricated with this technology. They enable precise drug delivery to the desired location within the body.

The MPO 100 enables 3D microprinting in various materials, some of which are biocompatible or biodegradable. Those can be used in tissue engineering to print scaffolds on which stem cells could grow to reconstruct organs. Advanced scaffolds like biphasic structures can be fabricated, fostering the regeneration of both cartilage and bone.

High-quality printed structures have found valuable applications in the medical field, and one such application is endoscopy. Optical fibers, with a diameter smaller than 0.5 mm, play a crucial role in endoscopy by providing quasi-noninvasive imaging of tissues. To enhance this technology, lenses can be 3D printed and attached to the end of optical fibers. Moreover, even phase delays and imperfections can be effectively addressed through phase correction techniques, particularly when employing multicore lenses.

Table-top thermal scanning probe lithography system with in-situ AFM imaging. Compact and compatible with glovebox.

Thermal scanning probe lithography tool with direct laser sublimation and grayscale modules. Excellent alternative to e-beam lithography tools.

Configurable and compact tabletop maskless aligner with raster scan and vector exposure modules.

Our most versatile system for research and prototyping with variable resolution and wide selection of options.

Multi-User Tool for 3D Lithography and 3D Microprinting of microstructures with applications in micro-optics, photonics, micro-mechanics and biomedical engineering.

The fastest maskless tool for rapid prototyping, the alternative to the mask aligners. Perfect for standard binary lithography.

We are always at your disposal.

Please send us your request.

To view the form, please enable Marketing cookies.

Subscribe to our newsletter

to receive the newest information.

To view the form, please enable Marketing cookies.