Microelectronics and Nanoelectronics

Rapid Prototyping of Microelectronic and Nanoelectronic Devices

-

Description

-

Advancements in microelectronics continuously rely on shrinking electronic devices and incorporating novel materials in active regions to achieve ever-higher speeds and new functionalities in device structures. This exploration of device architectures and use of new materials necessitates a rapid prototyping approach, enabling efficient testing and implementation of design changes.

Maskless lithography tools like the MLA, DWL and VPG+ series of Heidelberg Instruments, have emerged as a transformative technology in microelectronics lithography, offering numerous advantages compared to traditional photolithography. Their high resolution and maskless operation enable precise patterning of intricate microscale features, driving the limits of miniaturization. By eliminating physical masks, production costs are reduced, and rapid prototyping becomes feasible, accelerating development cycles. The technology’s flexibility allows for on-the-fly customization, tailoring each device on the wafer according to specific requirements.

The NanoFrazor facilitates nanoelectronics by combining Thermal Scanning Probe Lithography (t-SPL) with Direct Laser Sublimation. This thermal nanolithography technique enables the creation of nanostructures in the most critical regions of devices with the highest resolutions. The incorporation of laser direct sublimation of the same thermal resists allows for efficient writing of electrical traces and contacts. As a result, the NanoFrazor has become an ideal choice for nanoelectronic device fabrication, particularly in applications such as quantum electronics and molecular sensing.

-

Requirements

-

Dense patterns with high resolution features and low line edge roughness

Precise overlay of several layers

Compatibility with existing pattern transfer processes

Fast turnaround time with high flexibility

-

Solutions

-

Fast prototyping

No mask requiredNo charge accumulation

Critical insulating layers not impacted by charged particlesAccurate overlay

using alignment marks or none. The functional structured layer can be used as reference (NanoFrazor and Draw Mode)Ultra-high resolution (15 nm)

without the need for proximity effect corrections (NanoFrazor)High resolution

Minimum feature size 300 nm (DWL 66+)

Advancements in microelectronics continuously rely on shrinking electronic devices and incorporating novel materials in active regions to achieve ever-higher speeds and new functionalities in device structures. This exploration of device architectures and use of new materials necessitates a rapid prototyping approach, enabling efficient testing and implementation of design changes.

Maskless lithography tools like the MLA, DWL and VPG+ series of Heidelberg Instruments, have emerged as a transformative technology in microelectronics lithography, offering numerous advantages compared to traditional photolithography. Their high resolution and maskless operation enable precise patterning of intricate microscale features, driving the limits of miniaturization. By eliminating physical masks, production costs are reduced, and rapid prototyping becomes feasible, accelerating development cycles. The technology’s flexibility allows for on-the-fly customization, tailoring each device on the wafer according to specific requirements.

The NanoFrazor facilitates nanoelectronics by combining Thermal Scanning Probe Lithography (t-SPL) with Direct Laser Sublimation. This thermal nanolithography technique enables the creation of nanostructures in the most critical regions of devices with the highest resolutions. The incorporation of laser direct sublimation of the same thermal resists allows for efficient writing of electrical traces and contacts. As a result, the NanoFrazor has become an ideal choice for nanoelectronic device fabrication, particularly in applications such as quantum electronics and molecular sensing.

Dense patterns with high resolution features and low line edge roughness

Precise overlay of several layers

Compatibility with existing pattern transfer processes

Fast turnaround time with high flexibility

Fast prototyping

No charge accumulation

Accurate overlay

Ultra-high resolution (15 nm)

High resolution

Application images

suitable Systems

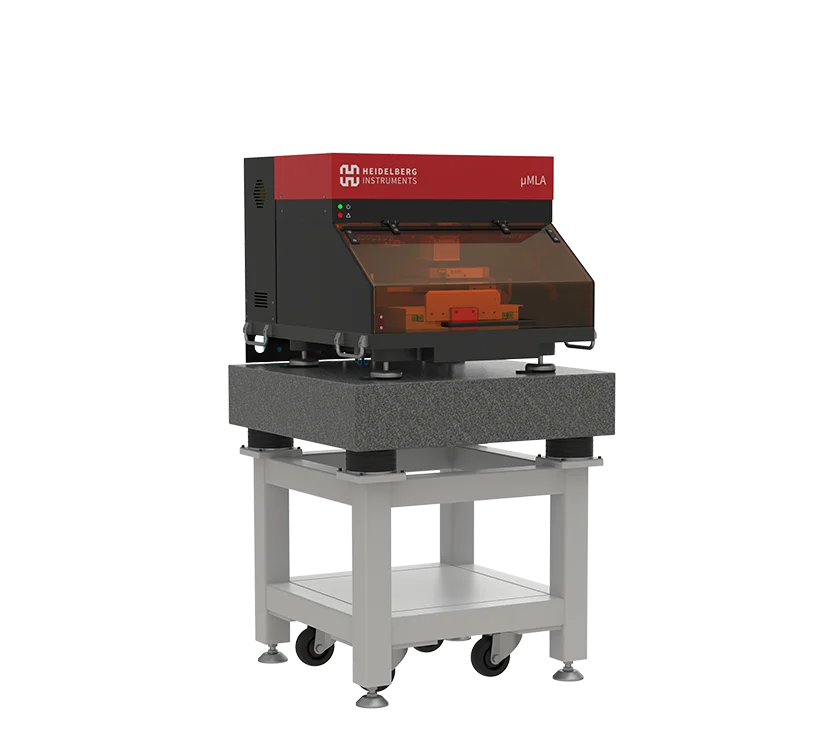

MLA 150

- Maskless Aligner

The fastest maskless tool for rapid prototyping, the alternative to the mask aligners. Perfect for standard binary lithography.

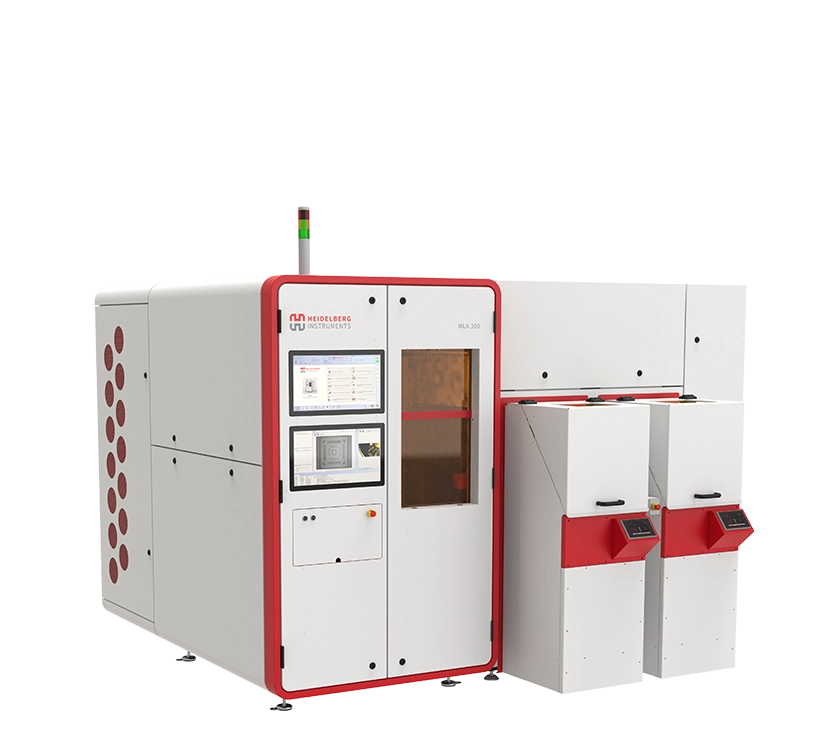

MLA 300

- Maskless Aligner

Optimized for industrial production with highest throughput and seamless integration into industrial production lines.

DWL 66+

- Direct Write Laser Lithography System

Our most versatile system for research and prototyping with variable resolution and wide selection of options.

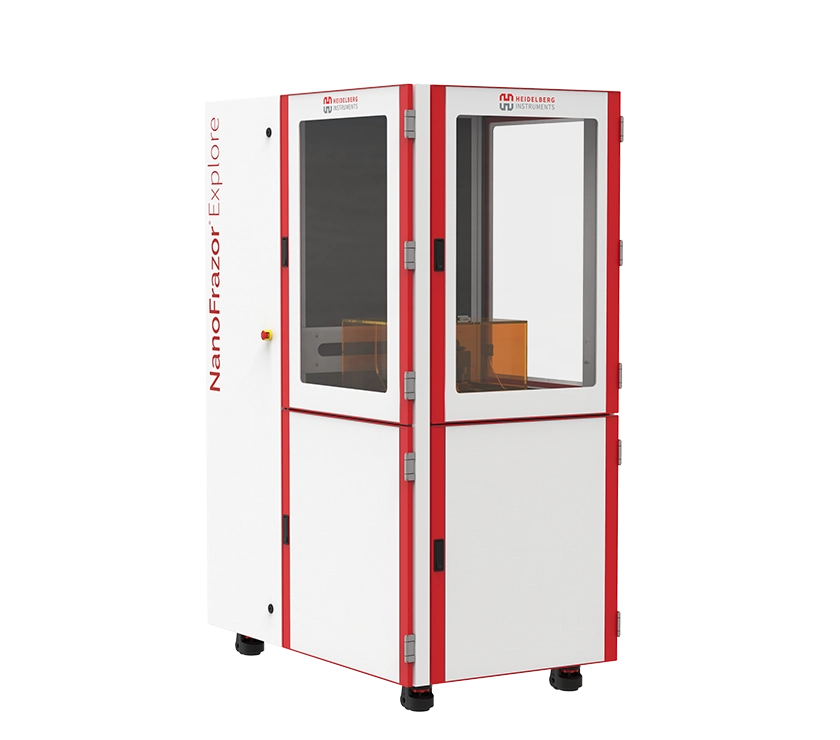

NanoFrazor Explore

- Thermal Scanning Probe Lithography System

Thermal scanning probe lithography tool with direct laser sublimation and grayscale modules. Excellent alternative to e-beam lithography tools.

NanoFrazor Scholar

- Thermal Scanning Probe Lithography System

Table-top thermal scanning probe lithography system with in-situ AFM imaging. Compact and compatible with glovebox.

VPG+ 200 / VPG+ 400

- Volume Pattern Generator

A production tool for standard photomasks and microstructures in i-line resists.

VPG 300 DI

- Maskless Stepper

Maskless direct imager for high-accuracy and high-resolution microstructures.

ULTRA

- Laser Mask Writer

A tool specifically designed to produce mature semiconductor photomasks.