Nanoimprint Templates

Down To Single-Nanometer Precision

-

Description

-

Nanoimprint lithography (NIL) is a high-throughput method used for replicating 2D or 2.5D nanostructures in photonics, optics, and nanofluidics applications. The process requires precise master templates generated through direct-write nano- or microlithography.

Although all Heidelberg Instruments are capable of producing 2D structures suitable for replication, grayscale lithography enables the production of intricate topographies. Maskless grayscale laser lithography is a fast technique that generates complex topographies in a photoresist layer on a substrate, which is then used as the master for replication. The DWL series is the ideal choice for rapidly fabricating such templates.

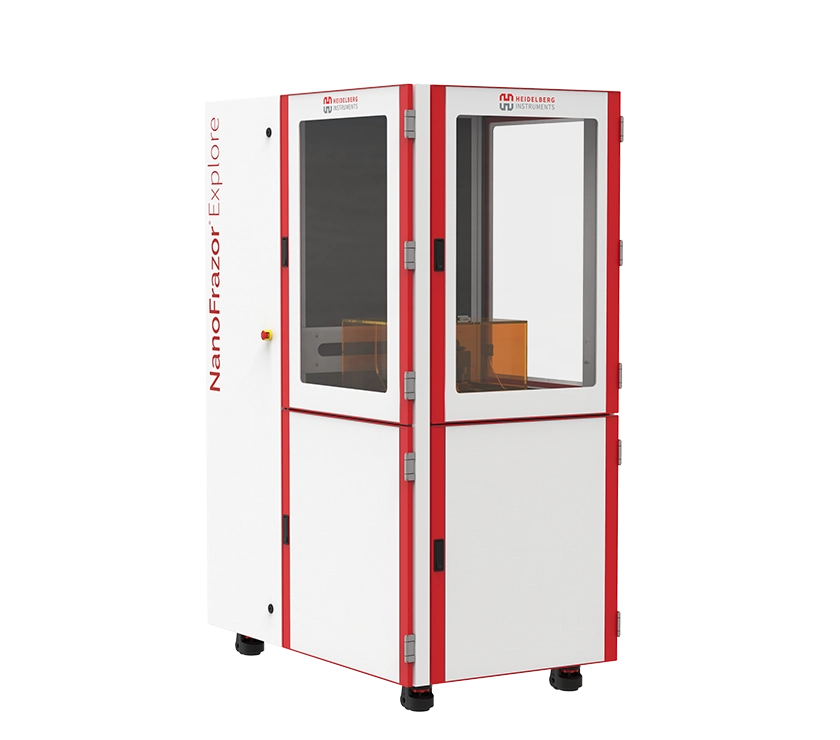

The NanoFrazor systems, which employ Thermal Scanning Probe grayscale lithography, can produce masters with higher lateral resolution and an impressive vertical resolution of 1 nm (Z-axis).

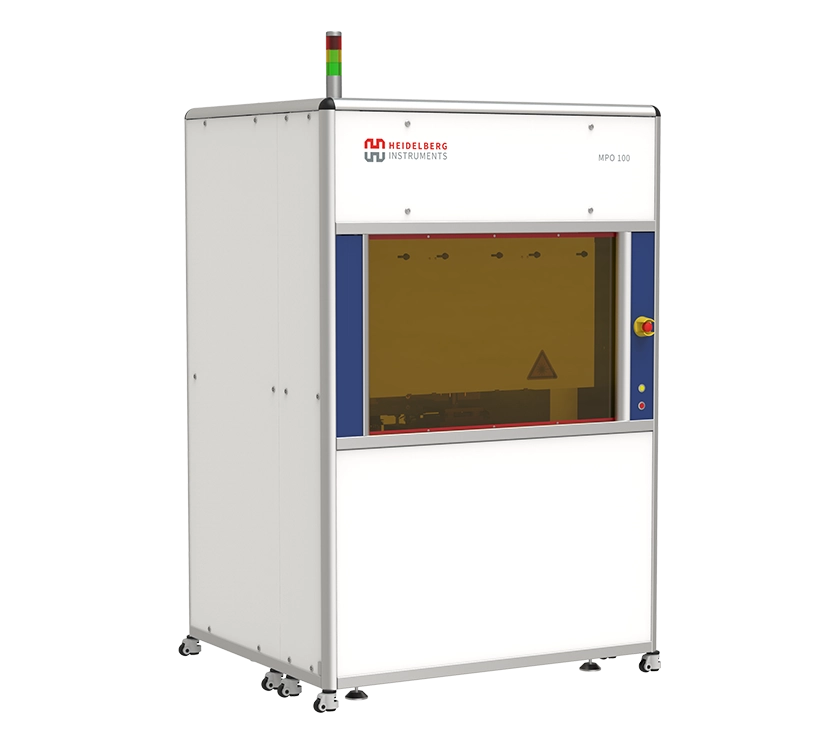

The MPO 100, which can create 3D structures using Two-Photon Polymerization, has the ability to manufacture extremely accurate 2.5D templates.

-

Requirements

-

High-resolution patterning over large areas

Accuracy of grayscale nanolithography

Additional processing steps (e.g. etching, electroforming) for the final master (NanoFrazor)

-

Solutions

-

Accurate grayscale lithography

down to single-nanometer accuracy (NanoFrazor)Ultra-high resolution

for templates and copiesCompatibility of resists

with various industrial NIL processesHigh write speed

to make grayscale masters even up to 1×1 m2

Nanoimprint lithography (NIL) is a high-throughput method used for replicating 2D or 2.5D nanostructures in photonics, optics, and nanofluidics applications. The process requires precise master templates generated through direct-write nano- or microlithography.

Although all Heidelberg Instruments are capable of producing 2D structures suitable for replication, grayscale lithography enables the production of intricate topographies. Maskless grayscale laser lithography is a fast technique that generates complex topographies in a photoresist layer on a substrate, which is then used as the master for replication. The DWL series is the ideal choice for rapidly fabricating such templates.

The NanoFrazor systems, which employ Thermal Scanning Probe grayscale lithography, can produce masters with higher lateral resolution and an impressive vertical resolution of 1 nm (Z-axis).

The MPO 100, which can create 3D structures using Two-Photon Polymerization, has the ability to manufacture extremely accurate 2.5D templates.

High-resolution patterning over large areas

Accuracy of grayscale nanolithography

Additional processing steps (e.g. etching, electroforming) for the final master (NanoFrazor)

Accurate grayscale lithography

Ultra-high resolution

Compatibility of resists

High write speed

Application images

suitable Systems

DWL 2000 GS / DWL 4000 GS

- Direct Write Laser Lithography System

The most advanced industrial grayscale lithography tool on the market.

MPO 100

- Two-Photon Polymerization Multi-User Tool

Multi-User Tool for 3D Lithography and 3D Microprinting of microstructures with applications in micro-optics, photonics, micro-mechanics and biomedical engineering.

NanoFrazor Explore

- Thermal Scanning Probe Lithography System

Thermal scanning probe lithography tool with direct laser sublimation and grayscale modules. Excellent alternative to e-beam lithography tools.

NanoFrazor Scholar

- Thermal Scanning Probe Lithography System

Table-top thermal scanning probe lithography system with in-situ AFM imaging. Compact and compatible with glovebox.

VPG 300 DI

- Maskless Stepper

Maskless direct imager for high-accuracy and high-resolution microstructures.