Accurate Pattern Placement

High Position and Overlay Accuracy

-

Description

-

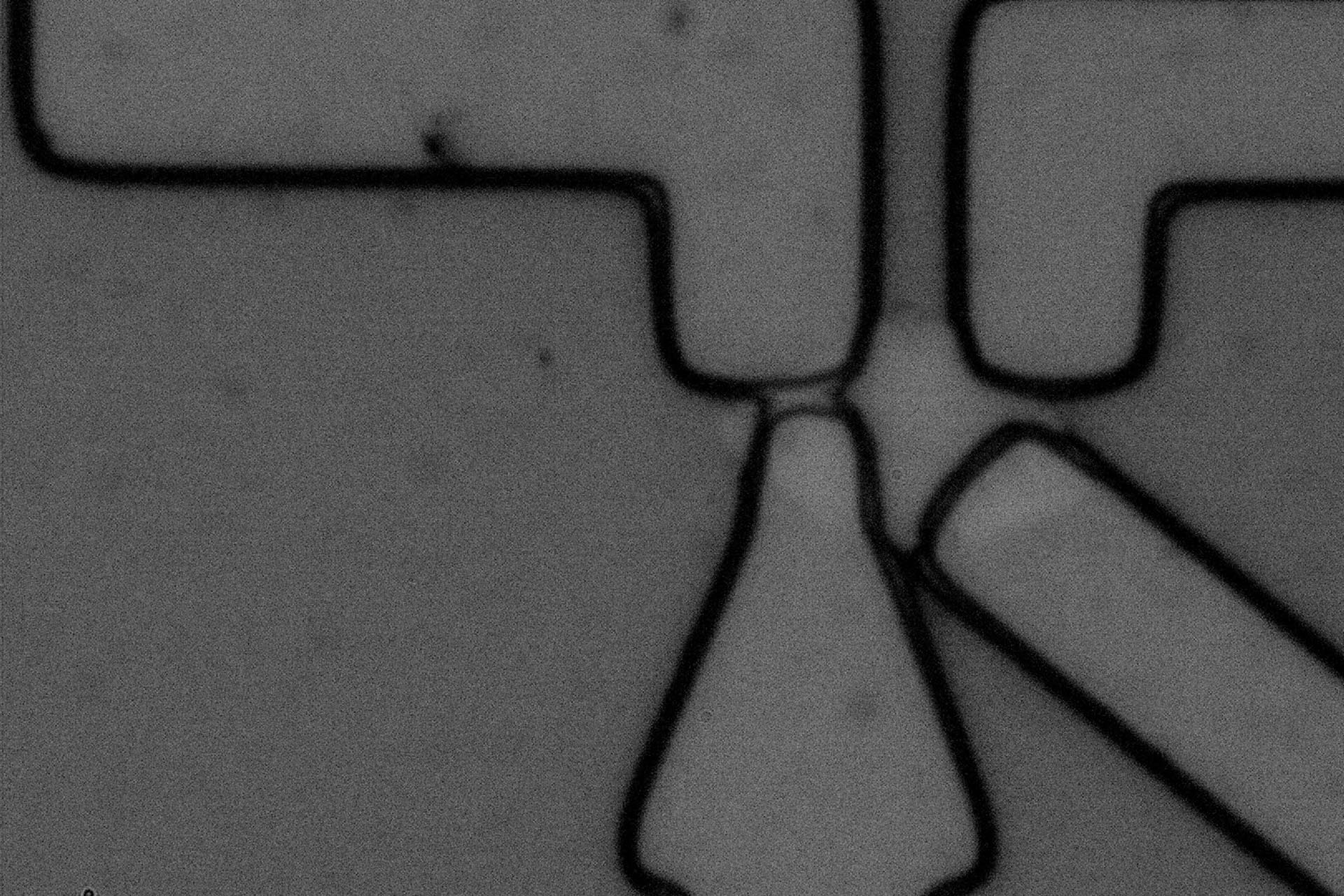

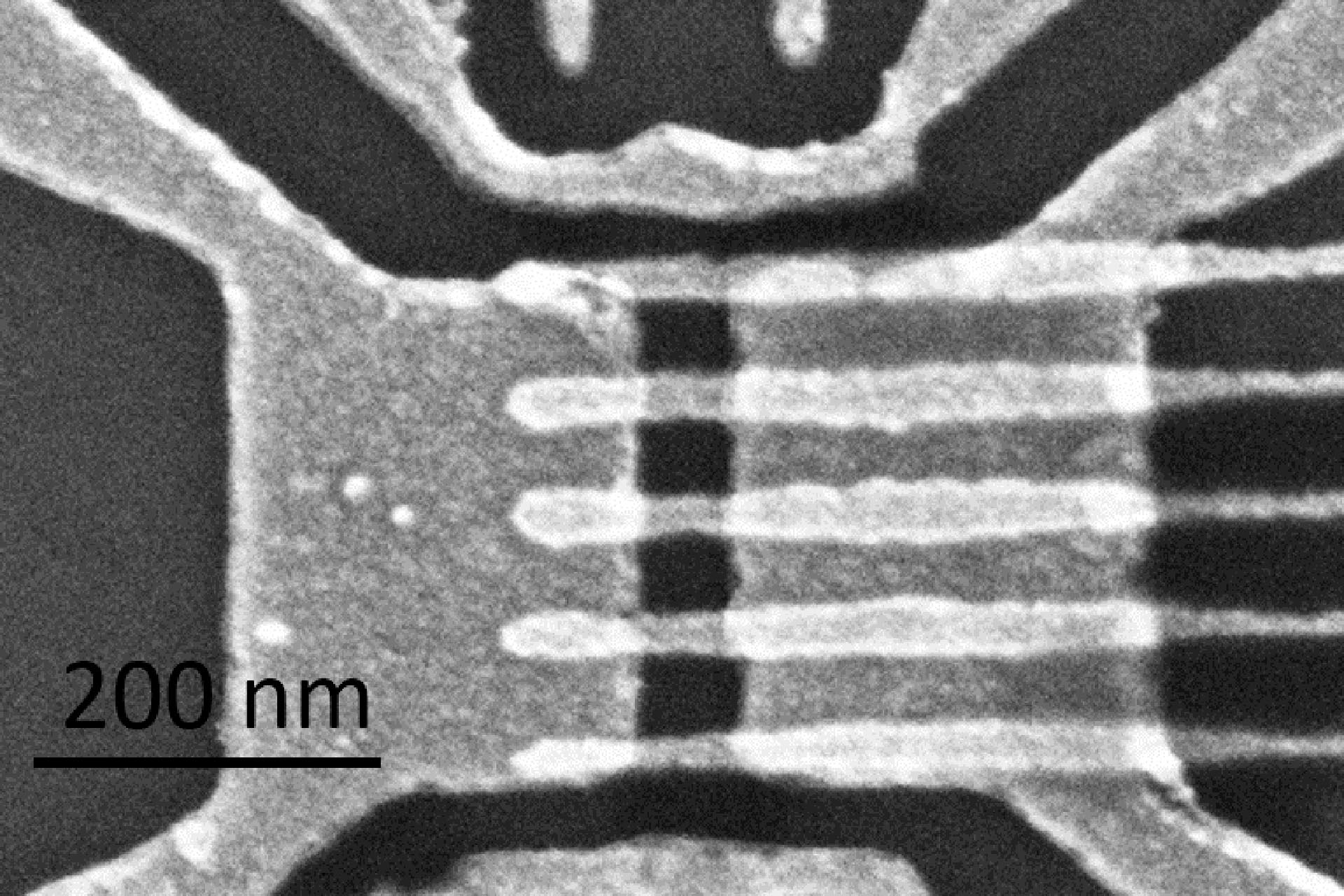

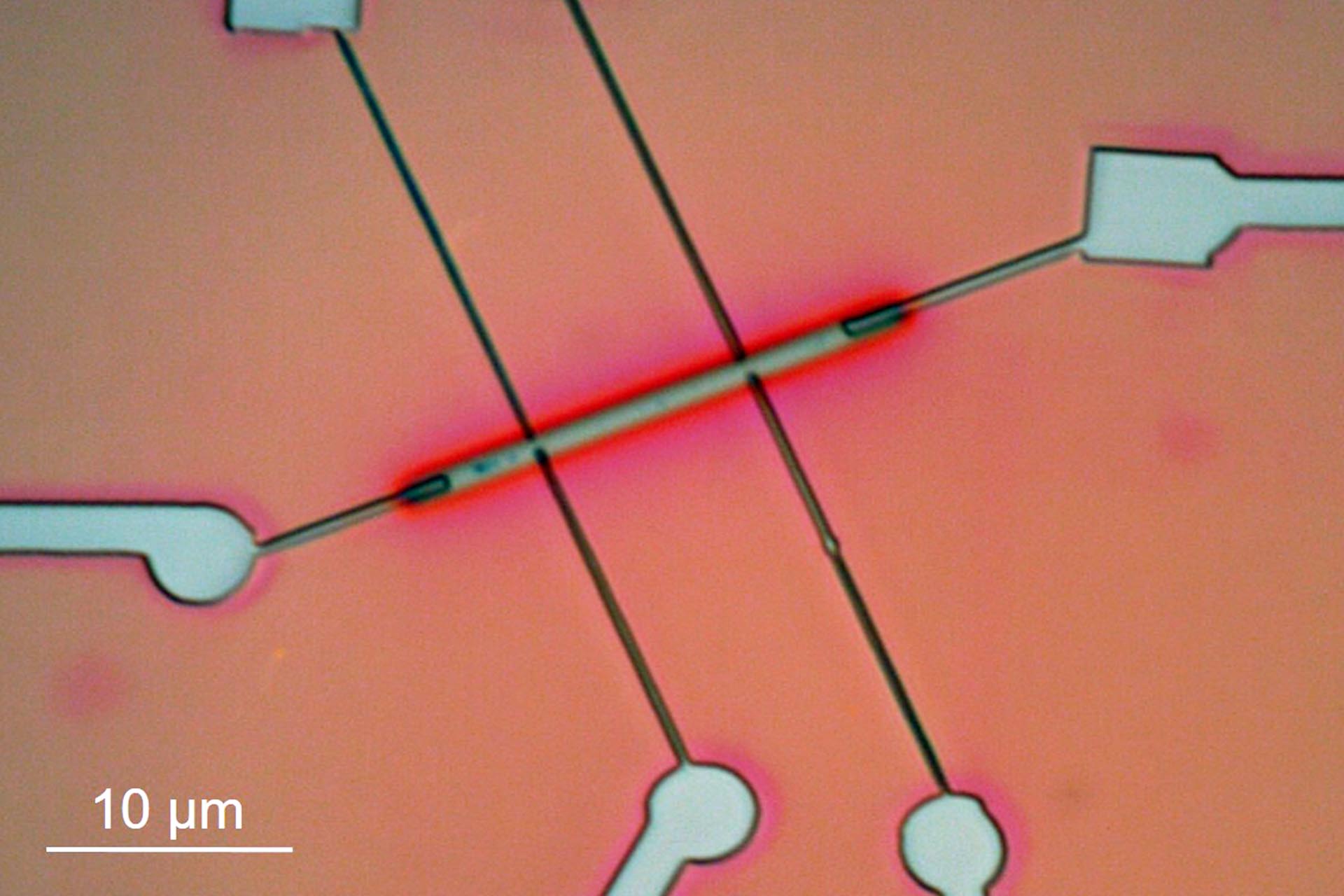

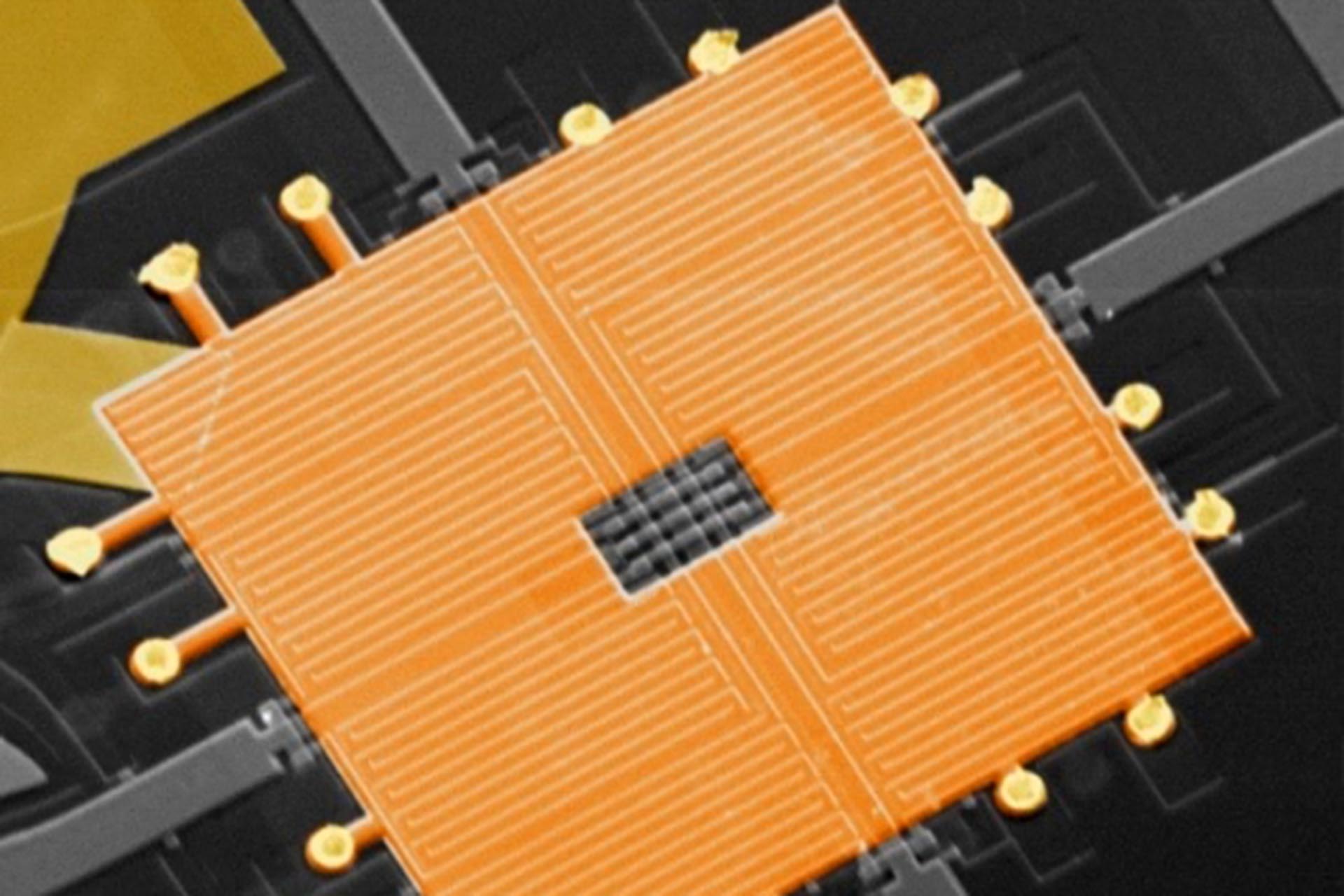

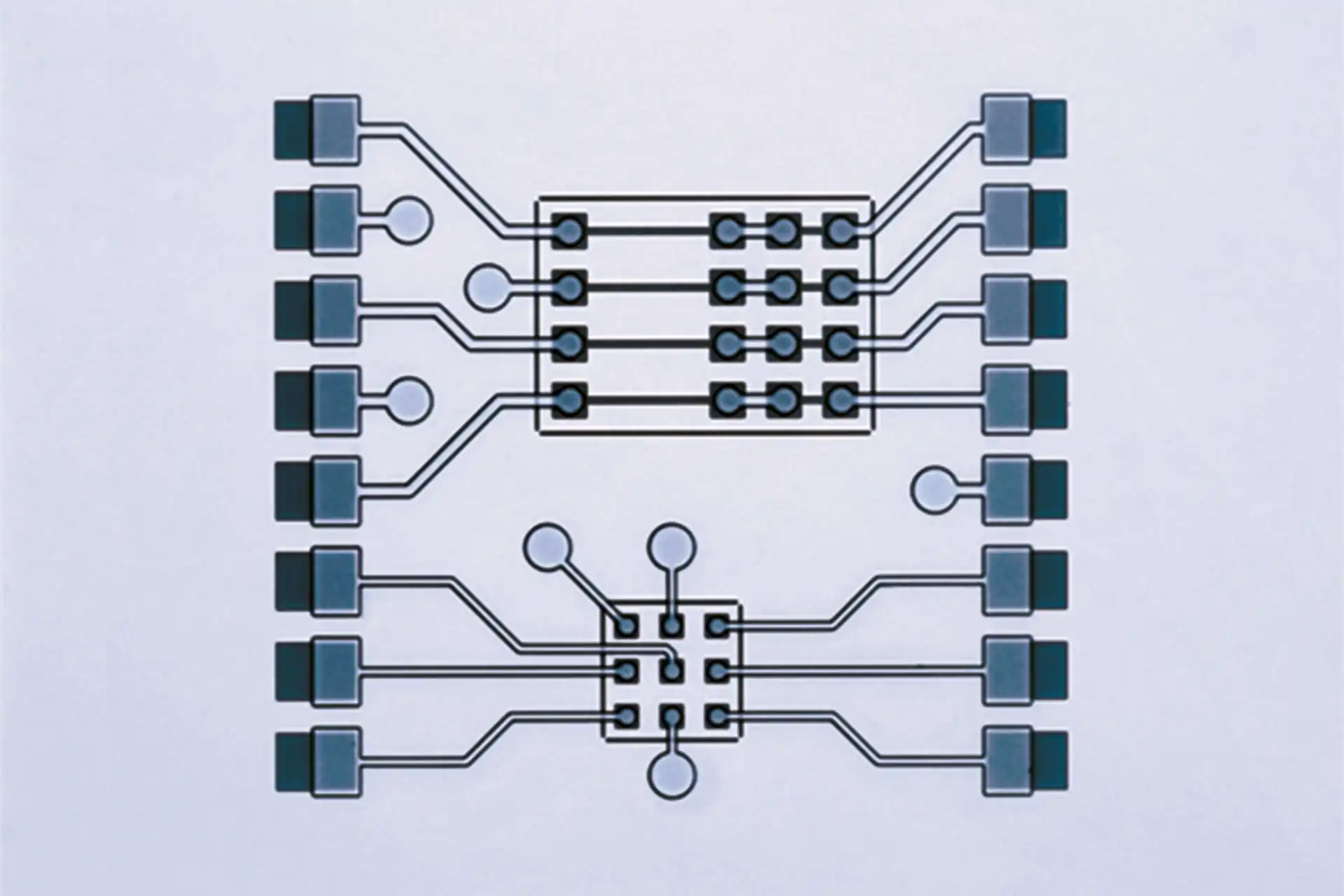

For some applications, local or global pattern placement accuracy is the most crucial requirement for lithography.

Our direct write lithography systems use differential laser interferometers, optical front- and/or backside alignment or in-situ imaging to measure various parameters for accurate positioning on the samples. Climate-controlled chambers and Zerodur sample chucks minimize thermal drifts that cannot be easily measured and compensated actively.

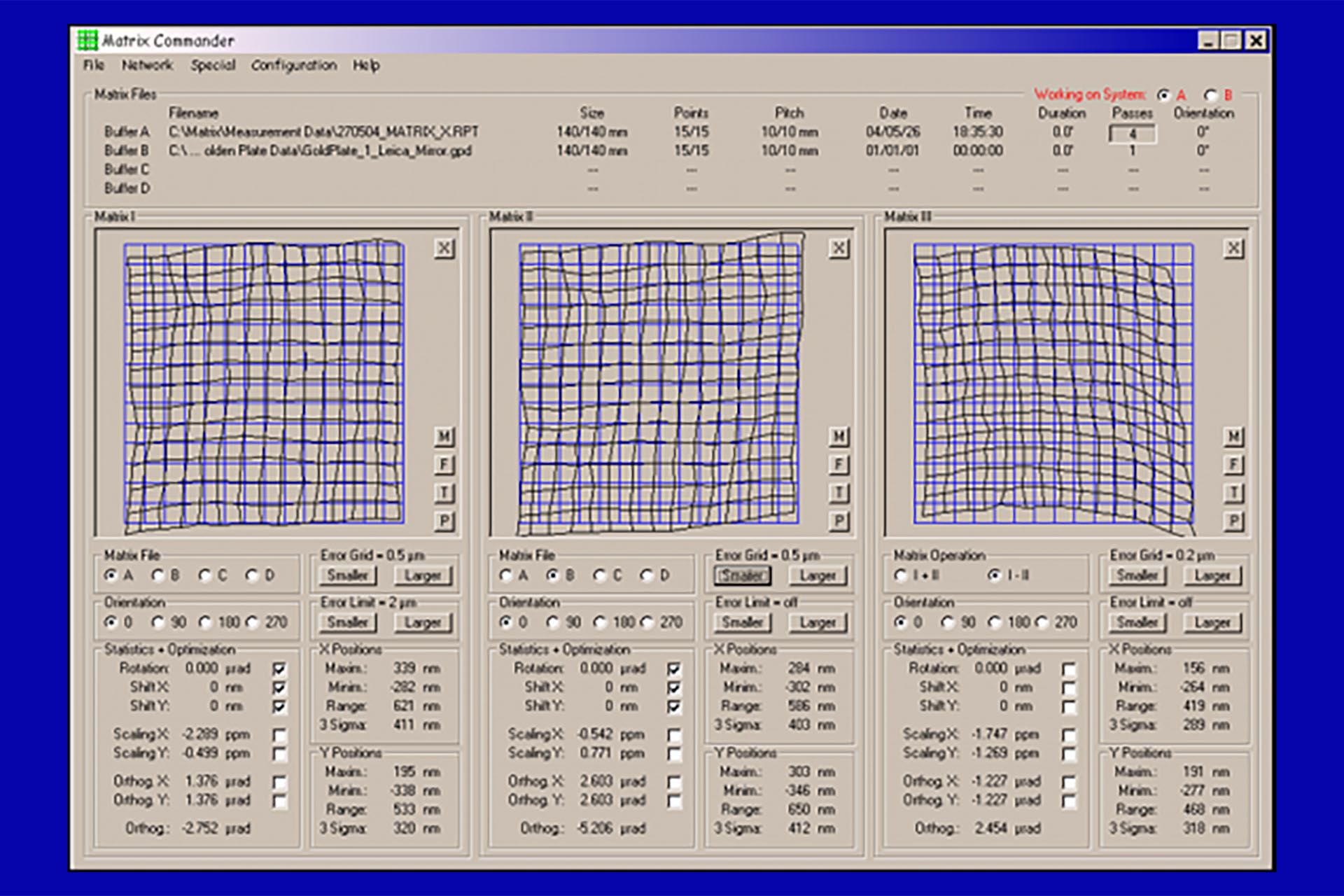

Direct-write lithography has key advantages for pattern placement accuracy as compared to mask aligners, steppers or imprint lithography tools that are bound to masks or stamps. Such tools cannot compensate for local or global imperfections from previous fabrication steps, from thermal effects or from bowing. In case of direct write lithography, the layout data can be individually adapted by local and global position matrix corrections (x-scale-errors, y-scale-errors, rotation, translation, orthogonality errors) to compensate for deviations from the desired pattern caused by sample or tool imperfections

For some applications, local or global pattern placement accuracy is the most crucial requirement for lithography.

Our direct write lithography systems use differential laser interferometers, optical front- and/or backside alignment or in-situ imaging to measure various parameters for accurate positioning on the samples. Climate-controlled chambers and Zerodur sample chucks minimize thermal drifts that cannot be easily measured and compensated actively.

Direct-write lithography has key advantages for pattern placement accuracy as compared to mask aligners, steppers or imprint lithography tools that are bound to masks or stamps. Such tools cannot compensate for local or global imperfections from previous fabrication steps, from thermal effects or from bowing. In case of direct write lithography, the layout data can be individually adapted by local and global position matrix corrections (x-scale-errors, y-scale-errors, rotation, translation, orthogonality errors) to compensate for deviations from the desired pattern caused by sample or tool imperfections

Related images

Suitable Systems

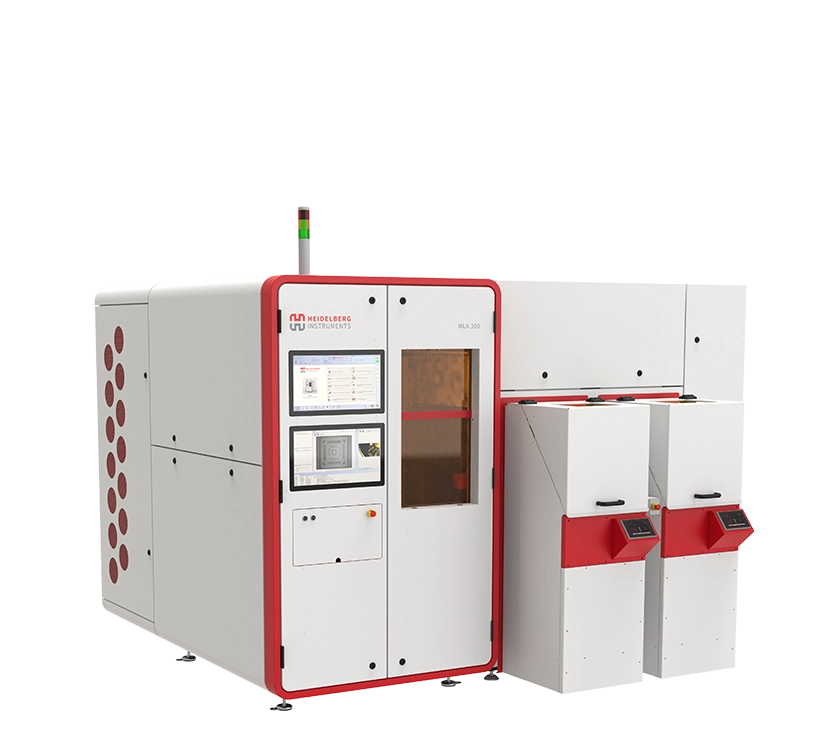

MLA 300

- Maskless Aligner

Optimized for industrial production with highest throughput and seamless integration into industrial production lines.

VPG+ 200 / VPG+ 400

- Volume Pattern Generator

A production tool for standard photomasks and microstructures in i-line resists.

DWL 66+

- Direct Write Laser Lithography System

Our most versatile system for research and prototyping with variable resolution and wide selection of options.

DWL 2000 GS / DWL 4000 GS

- Direct Write Laser Lithography System

The most advanced industrial grayscale lithography tool on the market.

VPG+ 800 / VPG+ 1400

- Volume Pattern Generator

Photomask production on large substrates, perfect for display applications.

ULTRA

- Laser Mask Writer

A tool specifically designed to produce mature semiconductor photomasks.

NanoFrazor Scholar

- Thermal Scanning Probe Lithography System

Table-top thermal scanning probe lithography system with in-situ AFM imaging. Compact and compatible with glovebox.

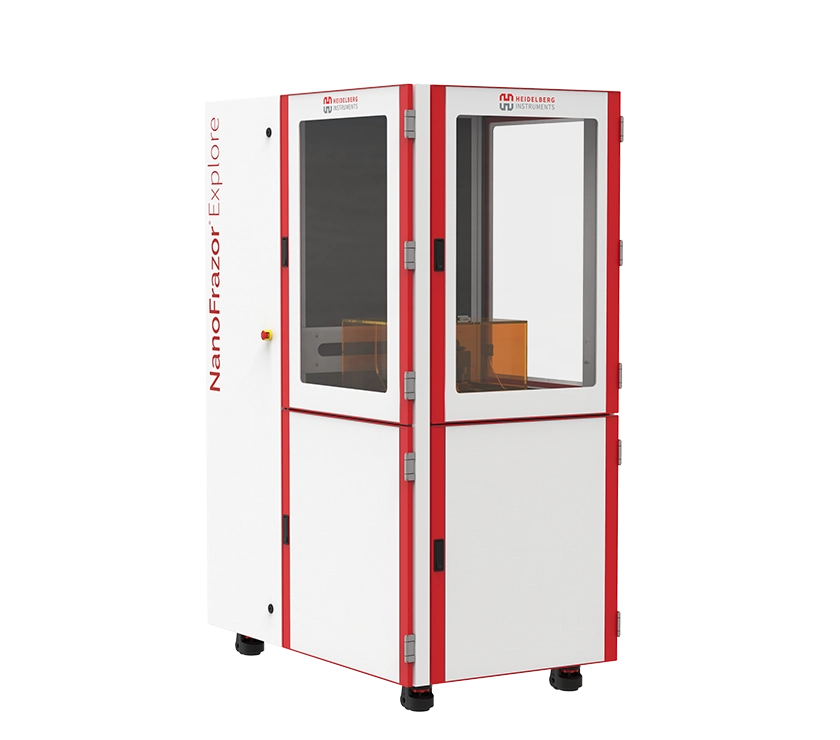

NanoFrazor Explore

- Thermal Scanning Probe Lithography System

Thermal scanning probe lithography tool with direct laser sublimation and grayscale modules. Excellent alternative to e-beam lithography tools.