Sensors

Heidelberg Instruments' Direct Writers Revolutionize Sensor Design with Unmatched Flexibility and Precision

-

Description

-

Heidelberg Instruments direct writers enable high precision, making them suitable for sensors with fine details and complex geometries (VPG & DWL series). They can work with a variety of materials, including polymers, metals, and ceramics. This flexibility is advantageous for creating sensors with diverse functional layers and optimizing the material properties for specific sensing applications.

Maskless lithography systems are valuable tools for rapid prototyping of sensor designs. Researchers and engineers can quickly iterate and test different sensor configurations without the need for time-consuming mask changes or complex lithography setups (VPG 300 DI, MLA series).

Two-Photon Polymerization allows for the fabrication of three-dimensional structures, which can be beneficial for sensors with complex architectures or those requiring specific spatial arrangements of sensing elements (MPO 100).

Thermal Scanning Probe Lithography with resolution capabilities as fine as 20 nm has the potential to elevate the sensitivity of the manufactured sensor. It opens up new possibilities for the development of sophisticated sensors and other nanoscale technologies.

-

Requirements

-

Resolution

Flexibility

Precise overlay of several layers

Patterning of various materials

-

Solutions

-

Accurate overlay

using alignment marks or none. The functional structured layer can be used as reference (NanoFrazor®, µMLA, MLA 150)Ultra-high resolution (15 nm) without the need for proximity effect corrections

(NanoFrazor®)High resolution

Minimum feature size 300 nm (DWL 66+) 500 nm (VPG 300 DI)Multiple wavelengths available

between 355 nm and 405 nm (Direct writers), 522 nm for 3D through Two-Photon Polymerization (TPP) (MPO 100)

Heidelberg Instruments direct writers enable high precision, making them suitable for sensors with fine details and complex geometries (VPG & DWL series). They can work with a variety of materials, including polymers, metals, and ceramics. This flexibility is advantageous for creating sensors with diverse functional layers and optimizing the material properties for specific sensing applications.

Maskless lithography systems are valuable tools for rapid prototyping of sensor designs. Researchers and engineers can quickly iterate and test different sensor configurations without the need for time-consuming mask changes or complex lithography setups (VPG 300 DI, MLA series).

Two-Photon Polymerization allows for the fabrication of three-dimensional structures, which can be beneficial for sensors with complex architectures or those requiring specific spatial arrangements of sensing elements (MPO 100).

Thermal Scanning Probe Lithography with resolution capabilities as fine as 20 nm has the potential to elevate the sensitivity of the manufactured sensor. It opens up new possibilities for the development of sophisticated sensors and other nanoscale technologies.

Resolution

Flexibility

Precise overlay of several layers

Patterning of various materials

Accurate overlay

Ultra-high resolution (15 nm) without the need for proximity effect corrections

High resolution

Multiple wavelengths available

Application images

suitable Systems

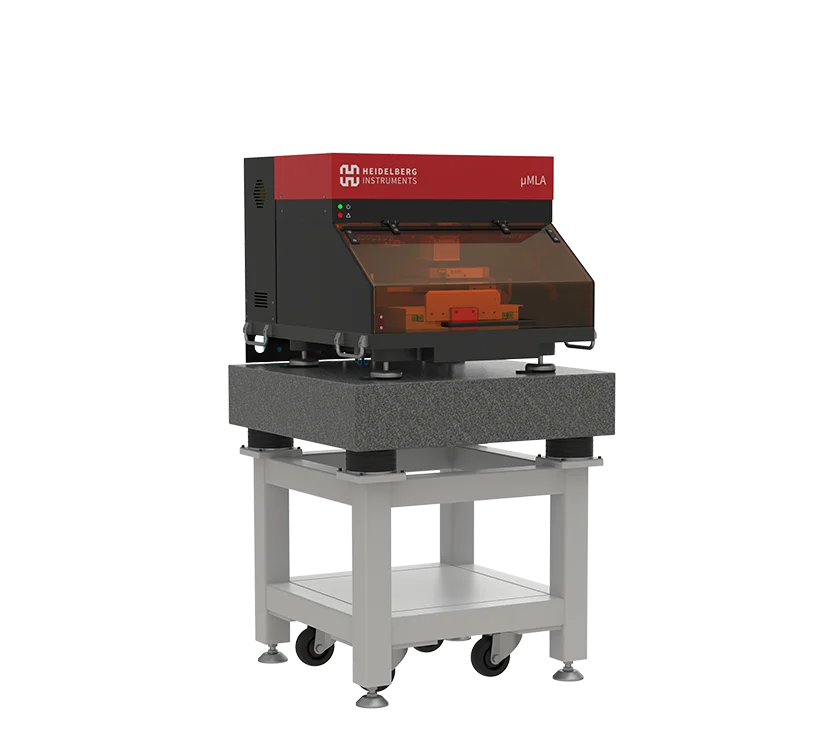

µMLA

- Maskless Aligner

Configurable and compact tabletop maskless aligner with raster scan and vector exposure modules.

DWL 66+

- Direct Write Laser Lithography System

Our most versatile system for research and prototyping with variable resolution and wide selection of options.

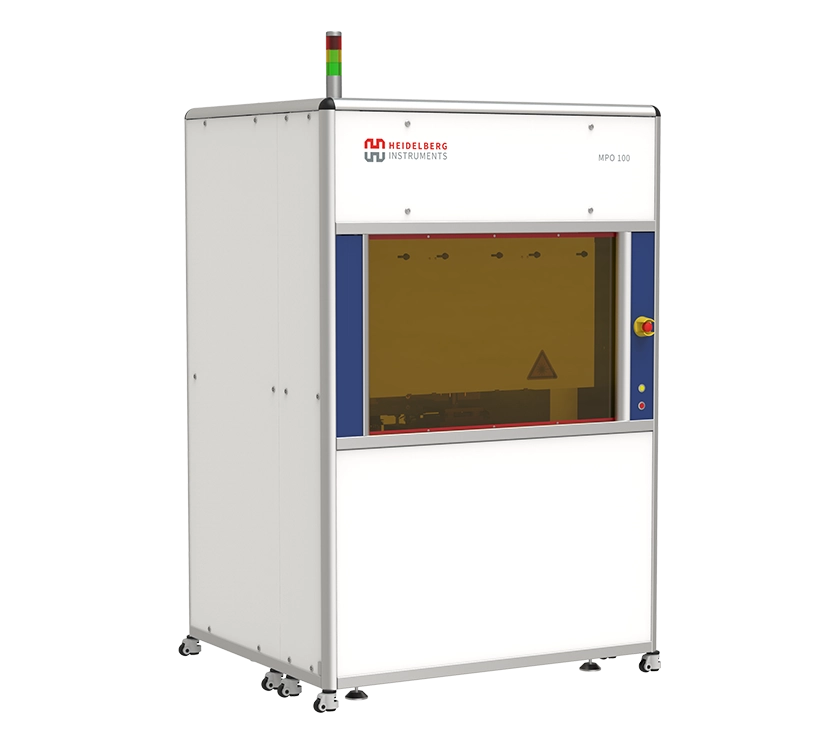

MPO 100

- Two-Photon Polymerization Multi-User Tool

Multi-User Tool for 3D Lithography and 3D Microprinting of microstructures with applications in micro-optics, photonics, micro-mechanics and biomedical engineering.

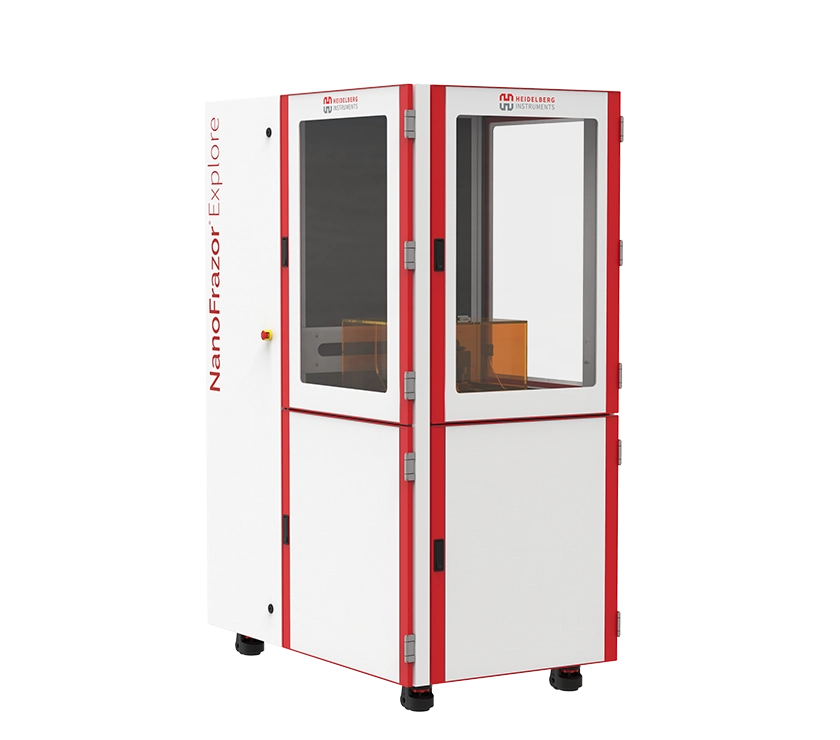

NanoFrazor Explore

- Thermal Scanning Probe Lithography System

Thermal scanning probe lithography tool with direct laser sublimation and grayscale modules. Excellent alternative to e-beam lithography tools.

NanoFrazor Scholar

- Thermal Scanning Probe Lithography System

Table-top thermal scanning probe lithography system with in-situ AFM imaging. Compact and compatible with glovebox.

VPG+ 200 / VPG+ 400

- Volume Pattern Generator

A production tool for standard photomasks and microstructures in i-line resists.

VPG+ 800 / VPG+ 1400

- Volume Pattern Generator

Photomask production on large substrates, perfect for display applications.

VPG 300 DI

- Maskless Stepper

Maskless direct imager for high-accuracy and high-resolution microstructures.

ULTRA

- Laser Mask Writer

A tool specifically designed to produce mature semiconductor photomasks.