Achieve high throughput and resolution.

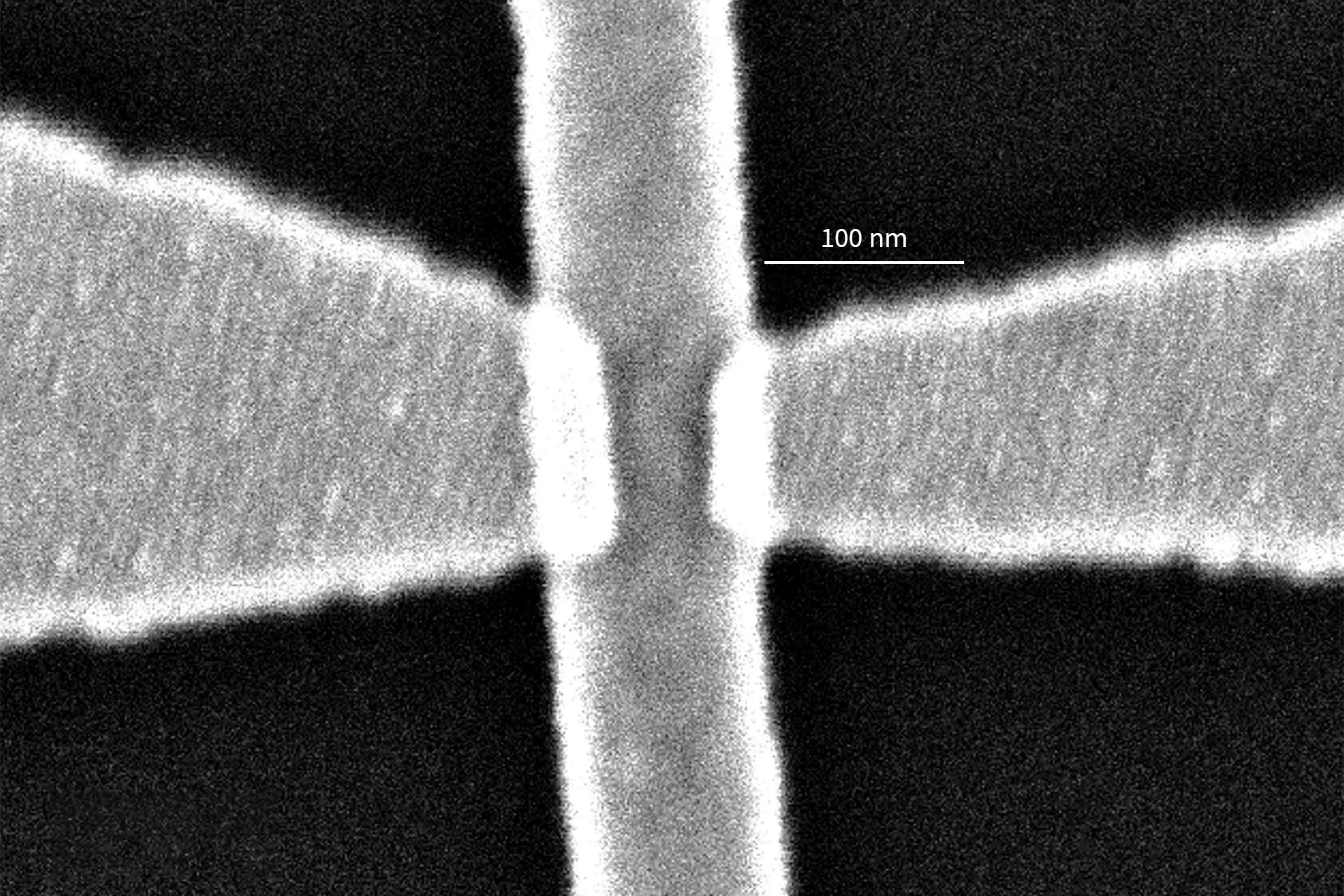

Despite its unique capacity for three-dimensional fabrication with minimal feature sizes below 100 nm, achieving high throughput with Two-Photon Polymerization (TPP) remains a challenge, when compared to established direct laser writing systems. To unlock the full potential of TPP, we propose a novel approach: the integration of standard lithography techniques with multiphoton lithography.

Combined exposures promise to improve efficiency in the fabrication of intricate structures and their surrounding areas, like frames or markers. This hybrid approach opens new possibilities for rapid prototyping and manufacturing in the micro- and nanoscale and may foster innovative applications in fields ranging from micro-optics to microelectromechanical systems (MEMS).

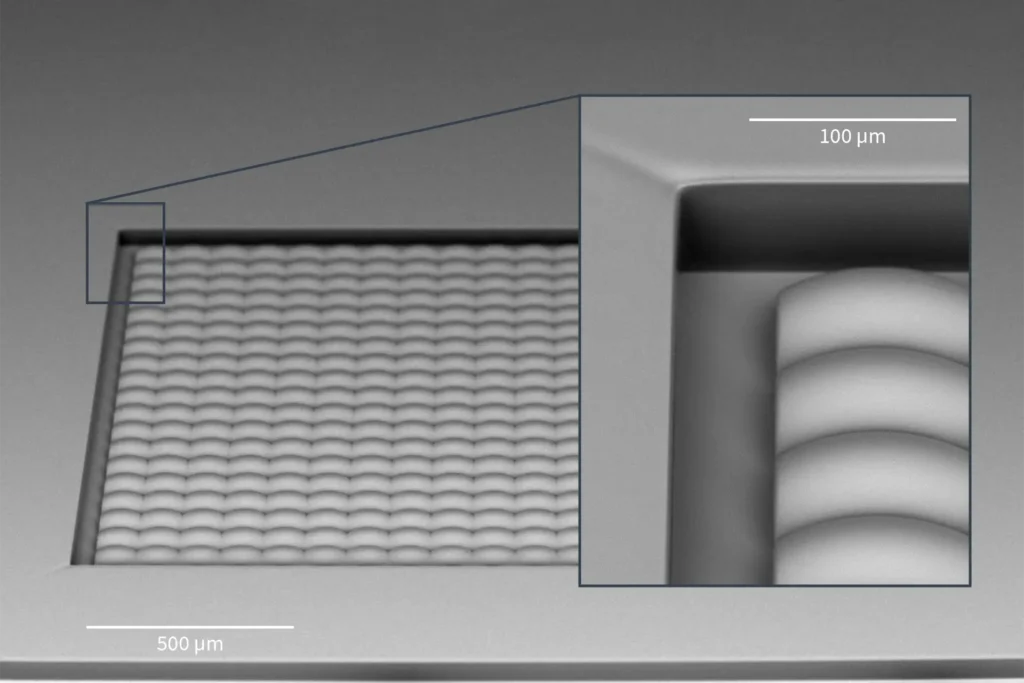

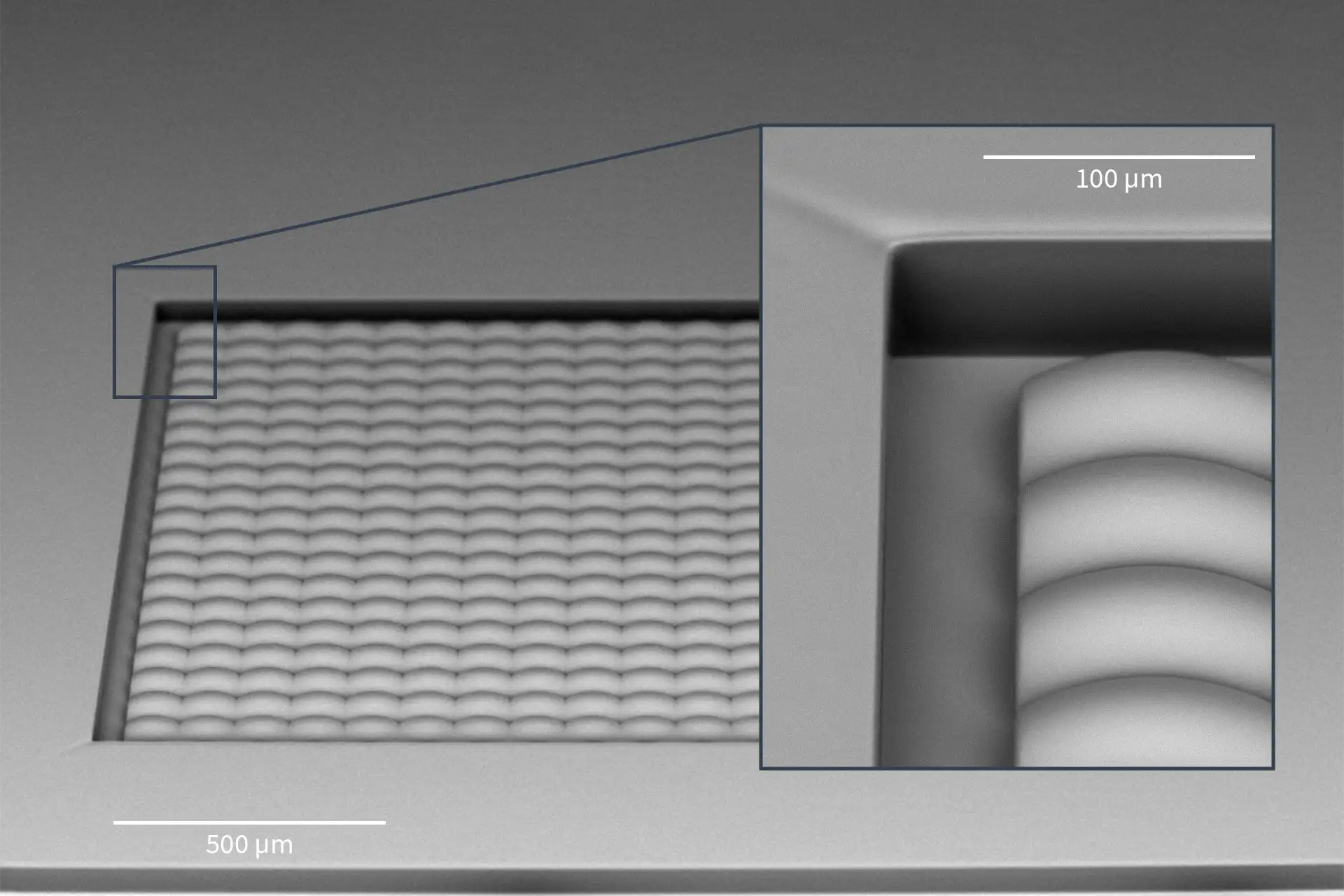

Pictured here are two microlens arrays. The 19×19 microlenses and 14×14 inverted microlenses were patterned with the MPO 100, our TPP-Multi-User Tool for 3D Lithography and 3D Microprinting. The frame around it was exposed using the MLA 150 Maskless Aligner.

Learn more about both tools on their respective product pages.

If you would like to know more, our team is on-hand to assist you with any questions you might have. Click the button below to contact us directly.

Stay updated and subscribe to our news: