Quantum Devices

A Mega-Trend with High Demands on Lithography

-

Description

-

There is a remarkable and rapidly growing interest in research and development activities focused on quantum devices worldwide. The potential of these future quantum devices to revolutionize computing, sensing, and data communication is tremendous. The prototypes and concepts for quantum devices are incredibly diverse, relying on a wide range of particles and quasi-particles, each chosen for their unique properties and interactions.

To support the advancements in quantum research, Heidelberg Instruments offers a comprehensive portfolio of tools that can manufacture various structures crucial for different areas of quantum research. Our extensive toolset includes the NanoFrazor systems, renowned for their ultra-high resolution capabilities. These systems allow for precise fabrication, minimizing damage and providing a bridge to future production. Additionally, our DWL series enables the creation of 2.5D topographies, while the VPG+ produces high-precision masks suitable for mass manufacturing. The MPO 100 tool is designed for manufacturing 3D micro-structures, and our Maskless Aligners (MLA) are ideal for multi-layer device fabrication.

In particular, the direct write lithography capabilities combined with high resolution offered by Heidelberg Instruments’ tools facilitate the development and production of quantum devices. Notably, the NanoFrazor stands out with its markerless overlay feature, leveraging the integrated reader for accurate alignment of multiple active regions on top of each other.

With Heidelberg Instruments’ portfolio of tools, researchers and engineers in the quantum field have access to advanced fabrication capabilities that enable them to push the boundaries of quantum device development. These tools support the realization of diverse quantum device concepts, paving the way for future breakthroughs in quantum computing, sensing, and data communication.

-

Requirements

-

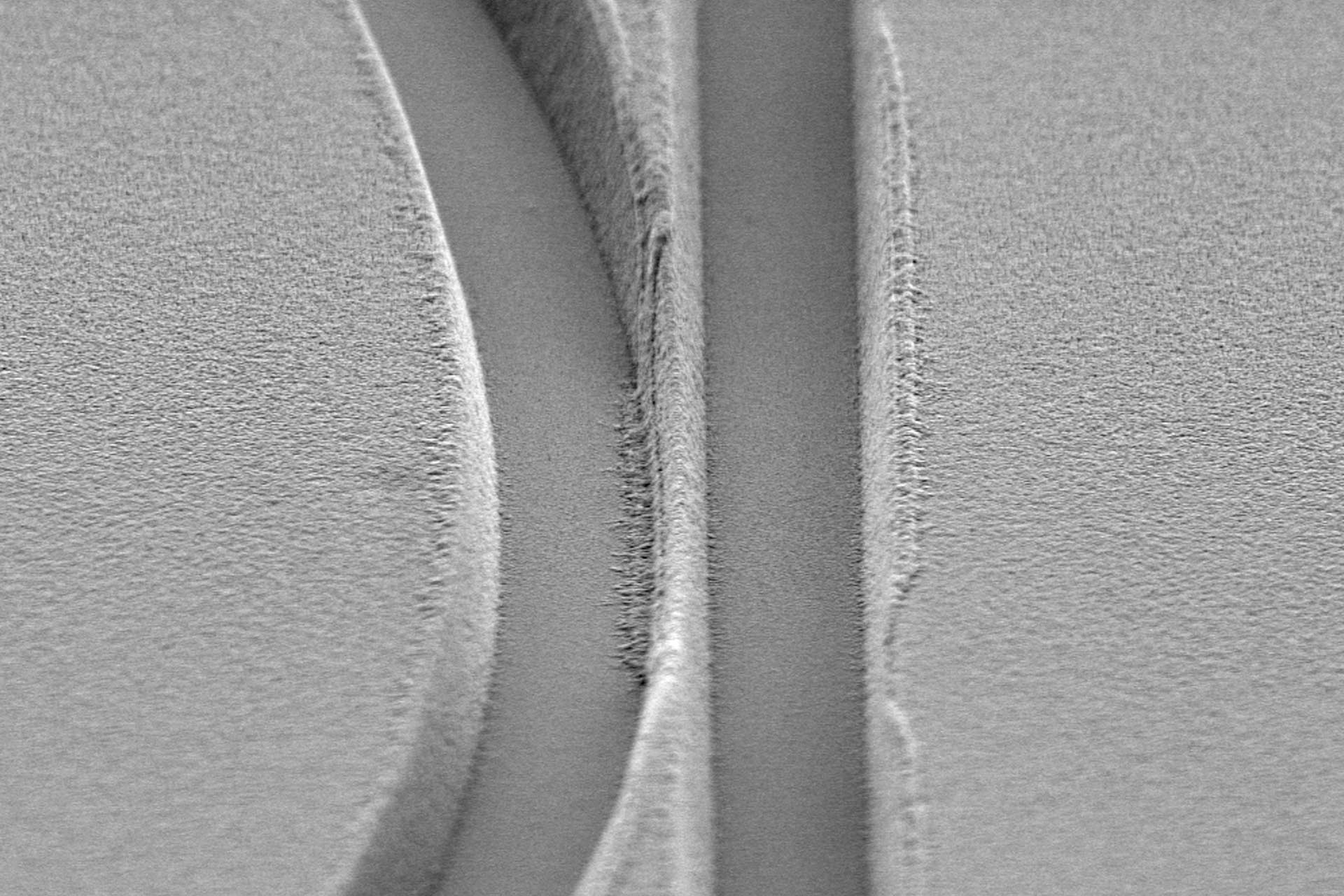

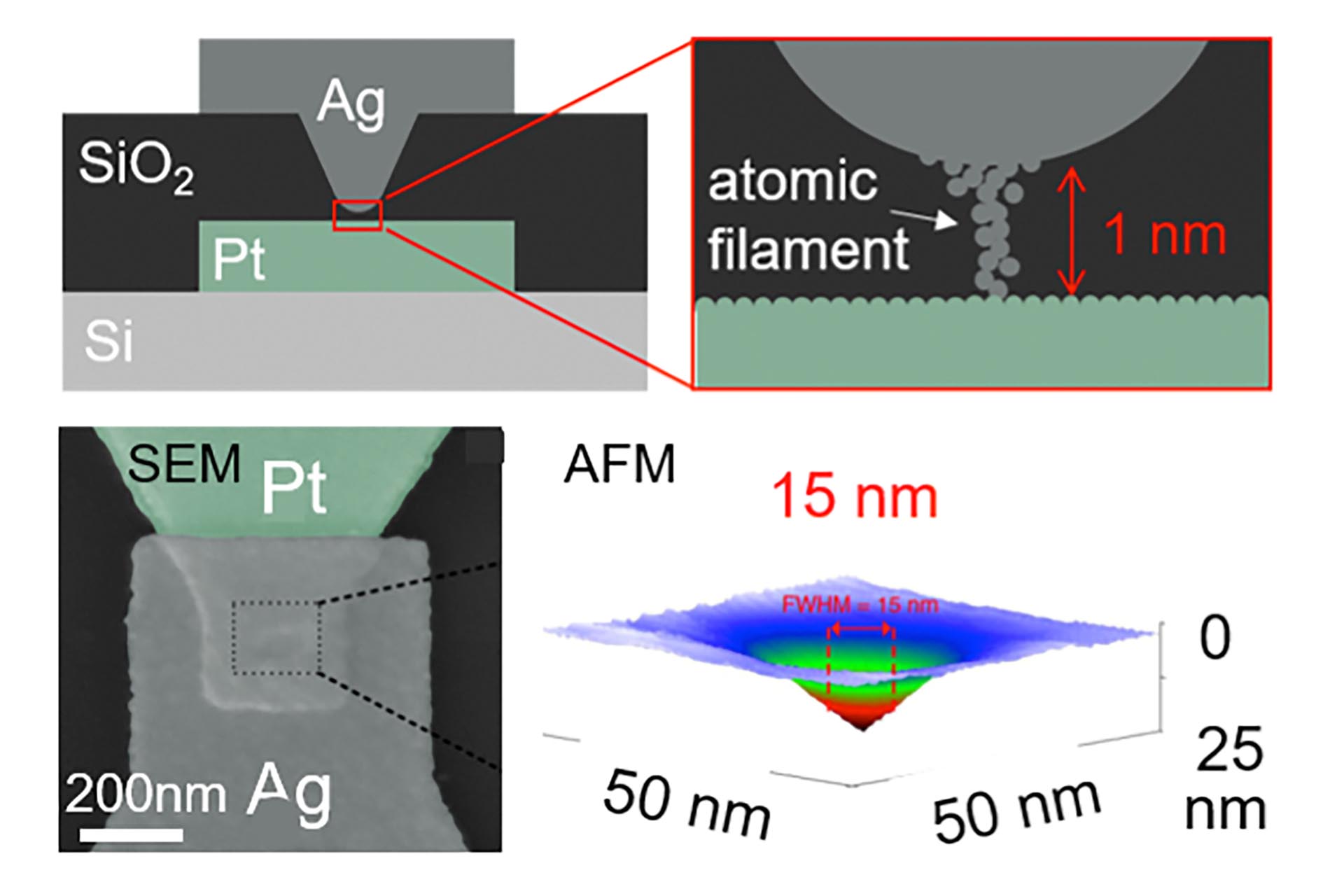

Ultra-high resolution patterning for well-defined structures (e.g., for tunneling gaps or plasmonic cavities)

Damage-free lithography, without deleterious effects on quantum materials (e.g., topological insulators)

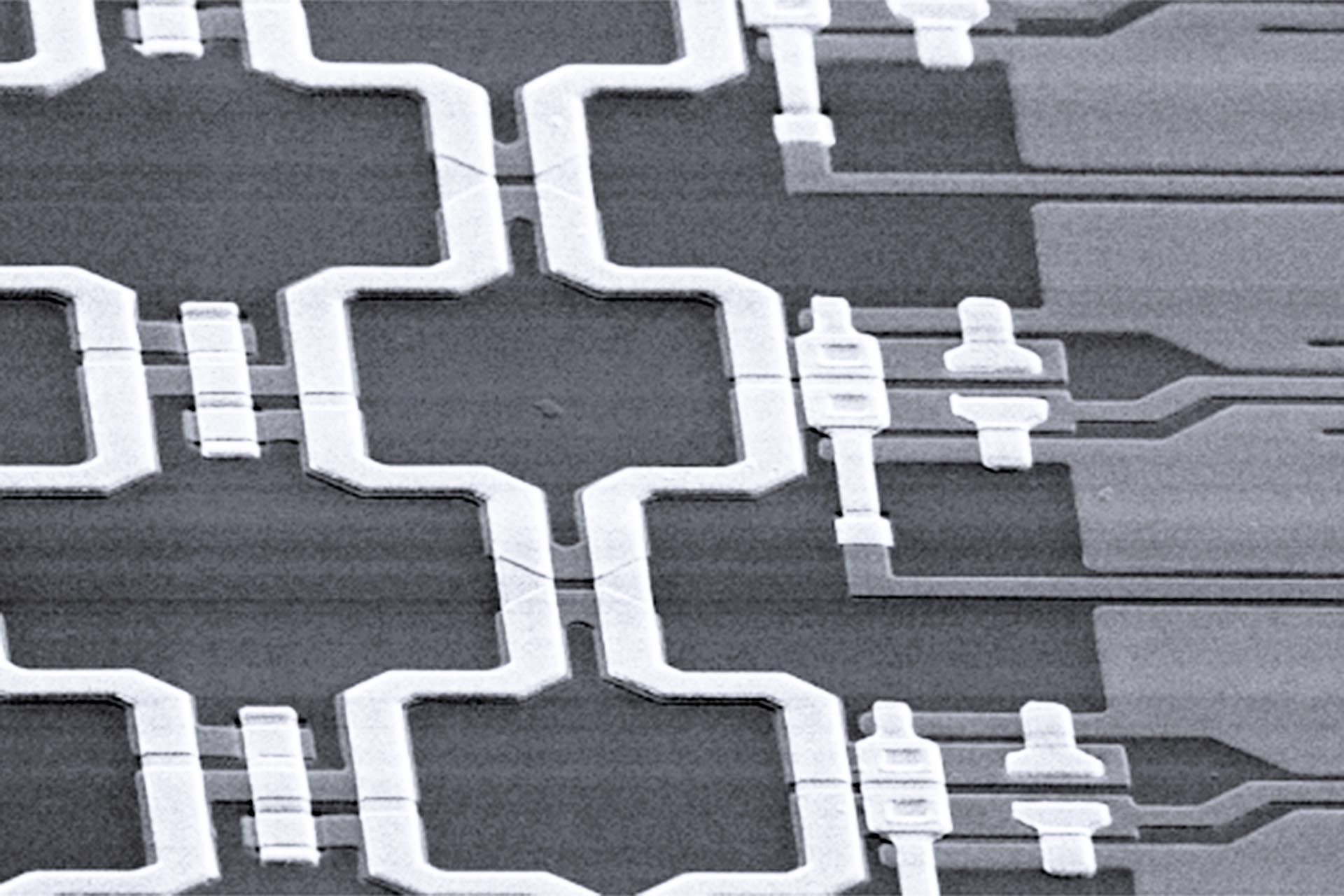

Fast and accurate placement of electrodes on low-dimensional materials with unknown positions (2D material flakes, dispersed nanowires, etc.)

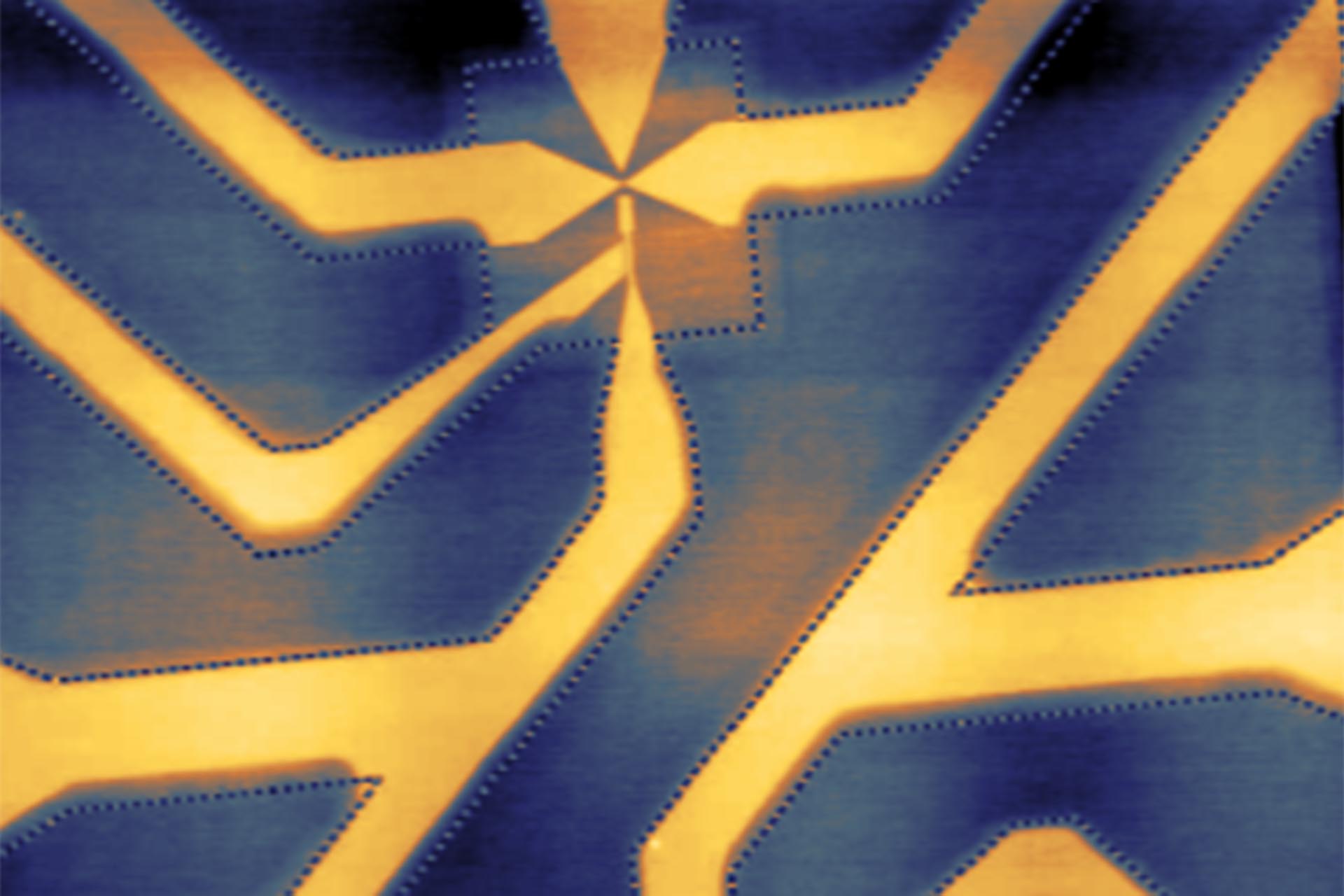

The grayscale environment and topography can be crucial for fine-tuning photon interactions in quantum devices

Rapid prototyping is a significant advantage in a dynamic research field.

-

Solutions

-

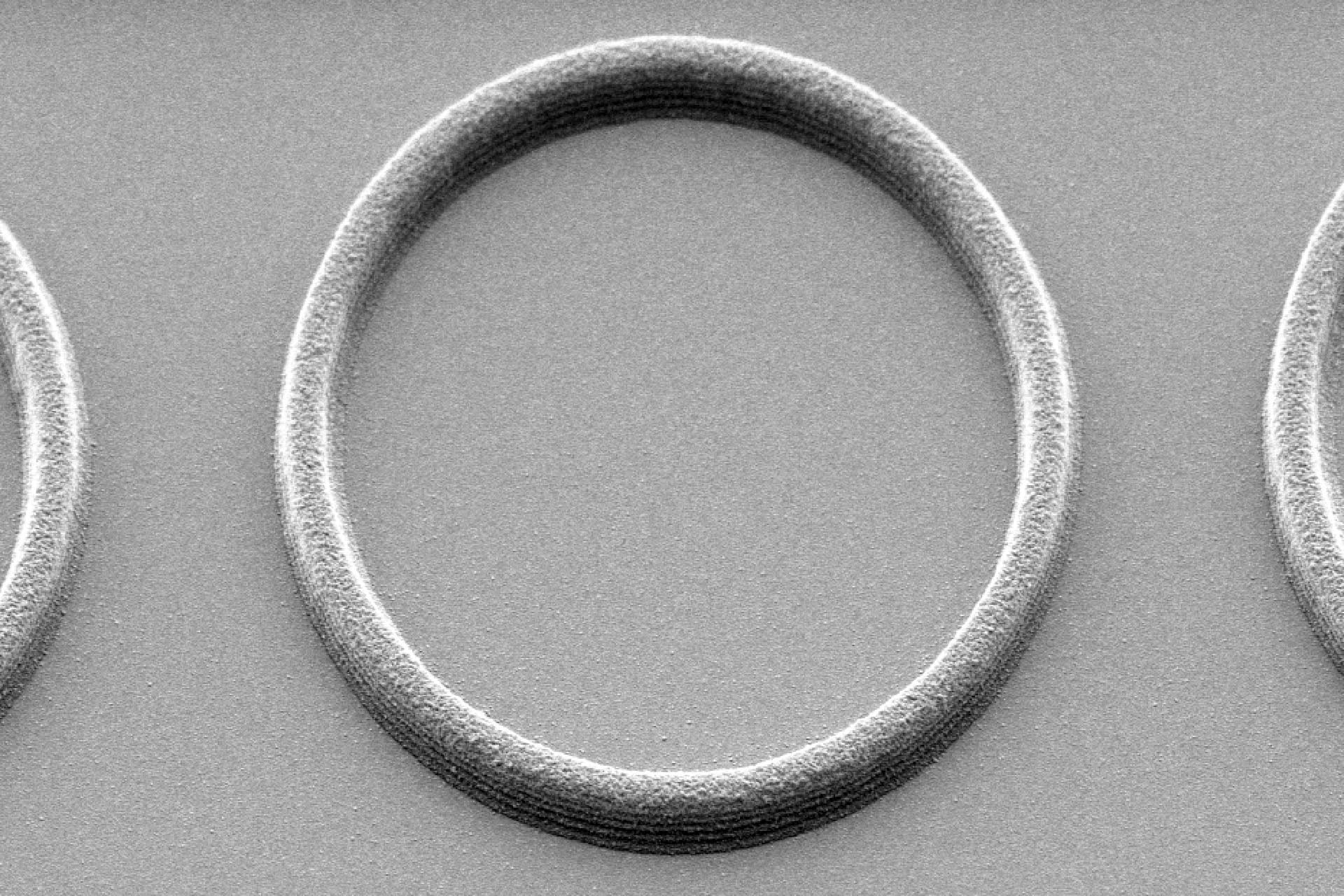

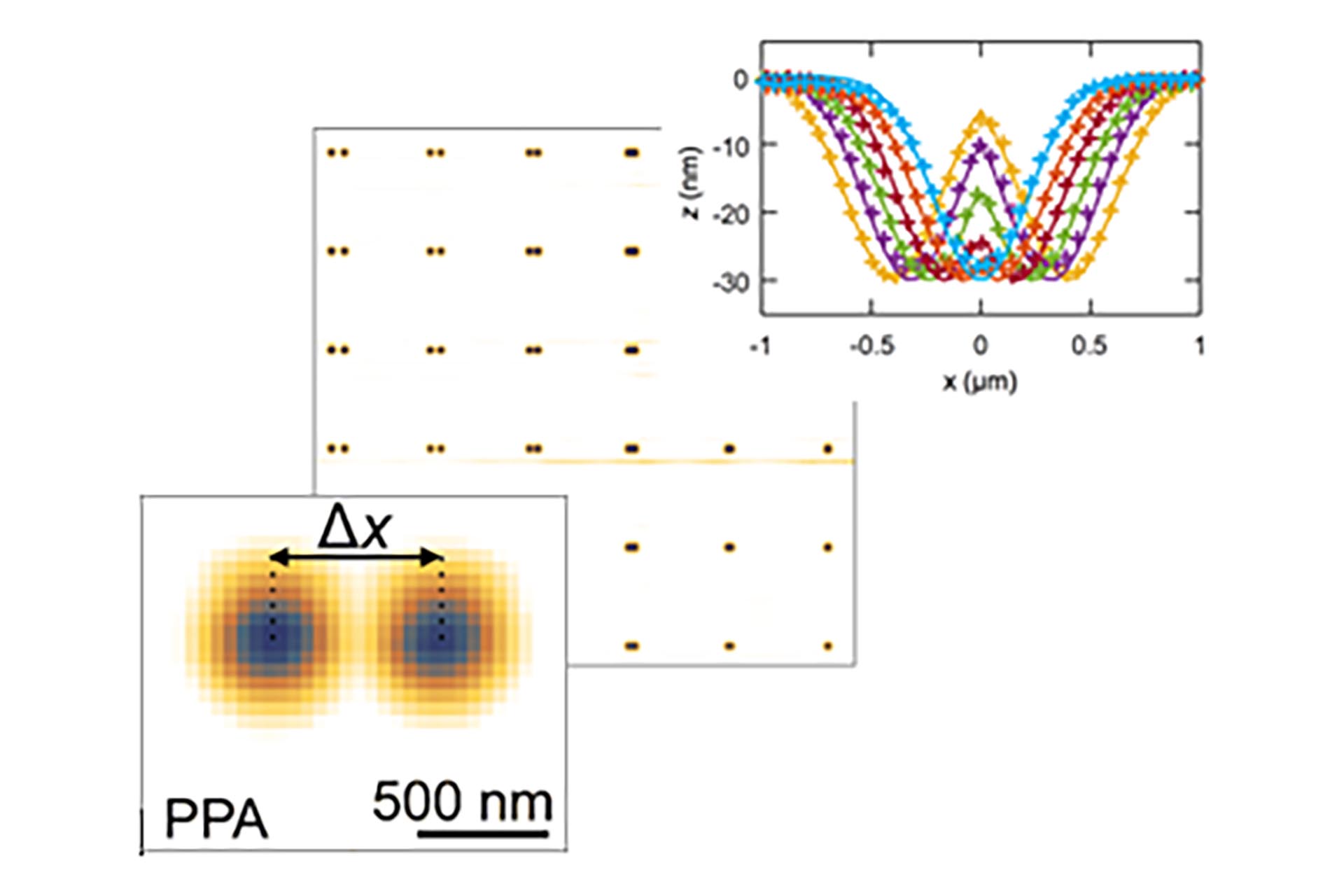

Ultra-high resolution

Required for well-defined features and gaps with low edge roughnessDamage-free nanolithography (NanoFrazor)

Non-destructive technique without using high-energy charged beams allows working with sensitive materialsAccurate overlay

Possible by simply drawing the electrodes onto the topography or optical image (NanoFrazor & MLA series)Accurate grayscale lithography

Used for control of grayscale topographies down to the single nanometer3D micro printing of optical interconnects

Used for high bandwidth data transmission and low power consumption (MPO 100)

There is a remarkable and rapidly growing interest in research and development activities focused on quantum devices worldwide. The potential of these future quantum devices to revolutionize computing, sensing, and data communication is tremendous. The prototypes and concepts for quantum devices are incredibly diverse, relying on a wide range of particles and quasi-particles, each chosen for their unique properties and interactions.

To support the advancements in quantum research, Heidelberg Instruments offers a comprehensive portfolio of tools that can manufacture various structures crucial for different areas of quantum research. Our extensive toolset includes the NanoFrazor systems, renowned for their ultra-high resolution capabilities. These systems allow for precise fabrication, minimizing damage and providing a bridge to future production. Additionally, our DWL series enables the creation of 2.5D topographies, while the VPG+ produces high-precision masks suitable for mass manufacturing. The MPO 100 tool is designed for manufacturing 3D micro-structures, and our Maskless Aligners (MLA) are ideal for multi-layer device fabrication.

In particular, the direct write lithography capabilities combined with high resolution offered by Heidelberg Instruments’ tools facilitate the development and production of quantum devices. Notably, the NanoFrazor stands out with its markerless overlay feature, leveraging the integrated reader for accurate alignment of multiple active regions on top of each other.

With Heidelberg Instruments’ portfolio of tools, researchers and engineers in the quantum field have access to advanced fabrication capabilities that enable them to push the boundaries of quantum device development. These tools support the realization of diverse quantum device concepts, paving the way for future breakthroughs in quantum computing, sensing, and data communication.

Ultra-high resolution patterning for well-defined structures (e.g., for tunneling gaps or plasmonic cavities)

Damage-free lithography, without deleterious effects on quantum materials (e.g., topological insulators)

Fast and accurate placement of electrodes on low-dimensional materials with unknown positions (2D material flakes, dispersed nanowires, etc.)

The grayscale environment and topography can be crucial for fine-tuning photon interactions in quantum devices

Rapid prototyping is a significant advantage in a dynamic research field.

Ultra-high resolution

Damage-free nanolithography (NanoFrazor)

Accurate overlay

Accurate grayscale lithography

3D micro printing of optical interconnects

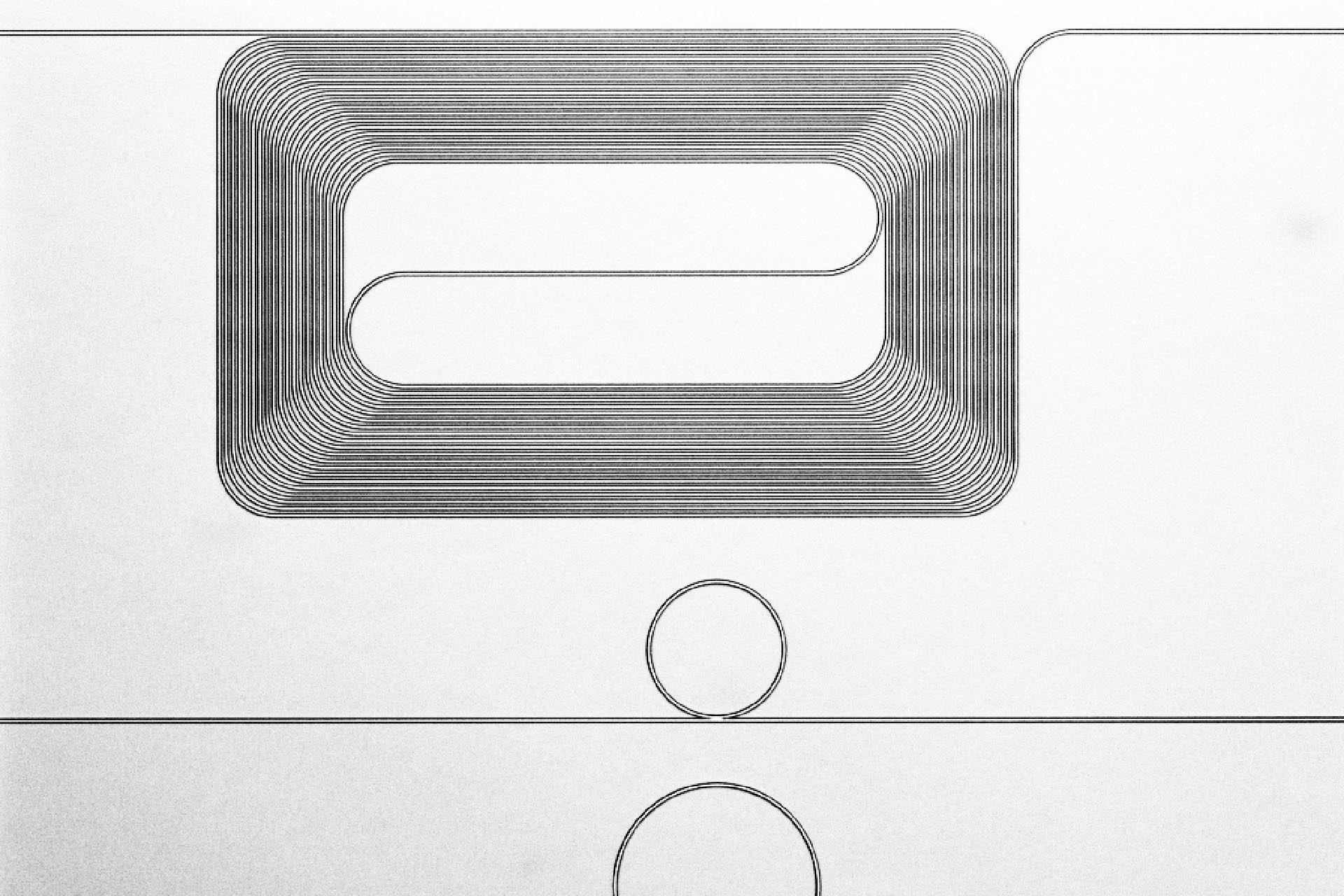

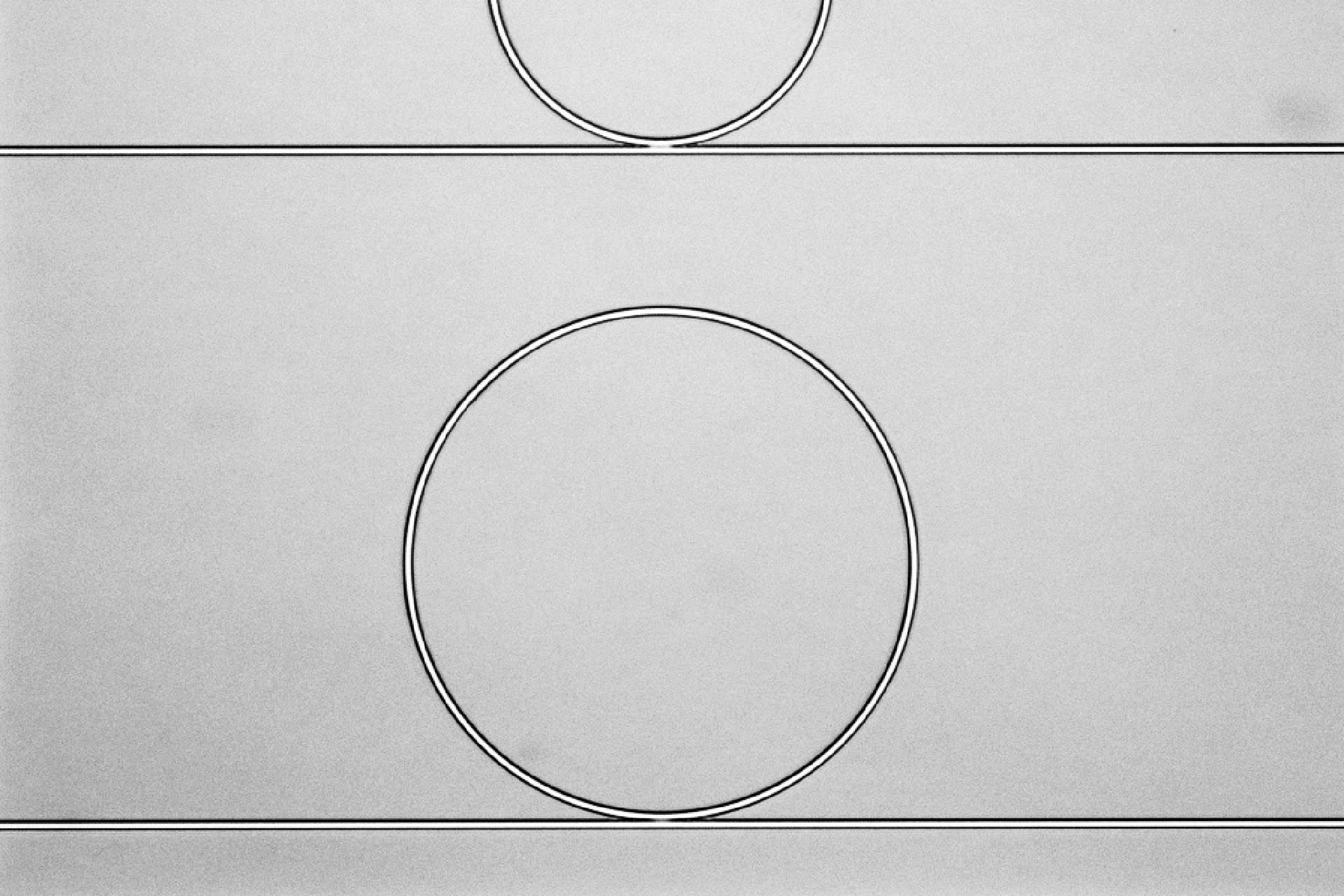

Application images

suitable Systems

DWL 66+

- Direct Write Laser Lithography System

Our most versatile system for research and prototyping with variable resolution and wide selection of options.

DWL 2000 GS / DWL 4000 GS

- Direct Write Laser Lithography System

The most advanced industrial grayscale lithography tool on the market.

MLA 150

- Maskless Aligner

The fastest maskless tool for rapid prototyping, the alternative to the mask aligners. Perfect for standard binary lithography.

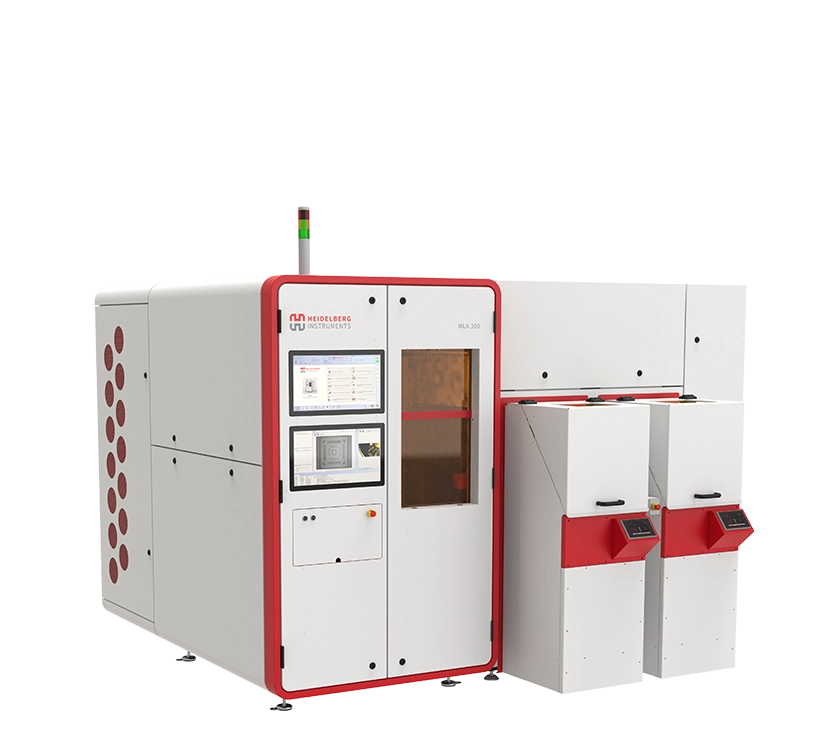

MLA 300

- Maskless Aligner

Optimized for industrial production with highest throughput and seamless integration into industrial production lines.

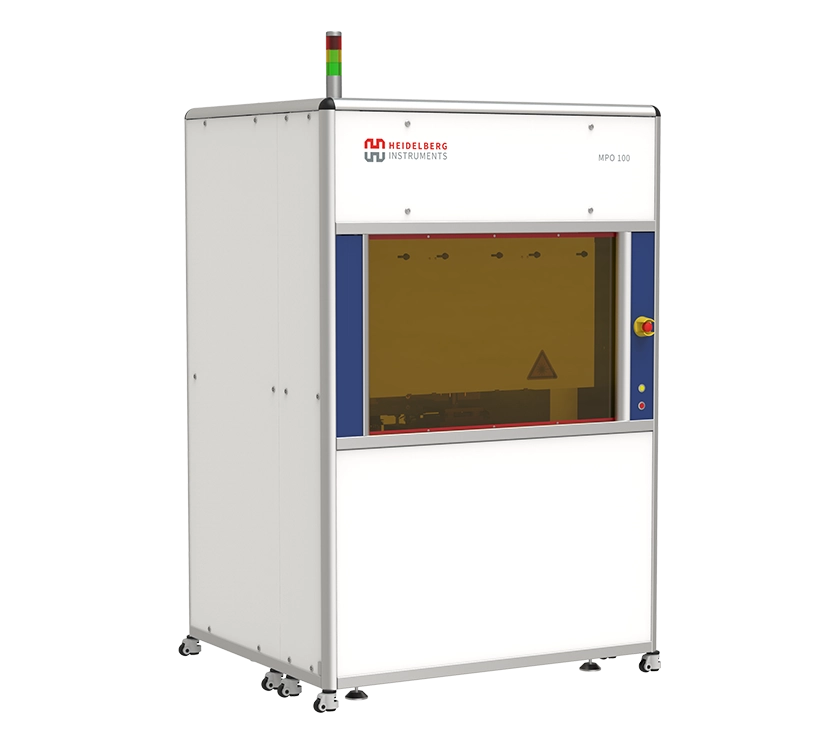

MPO 100

- Two-Photon Polymerization Multi-User Tool

Multi-User Tool for 3D Lithography and 3D Microprinting of microstructures with applications in micro-optics, photonics, micro-mechanics and biomedical engineering.

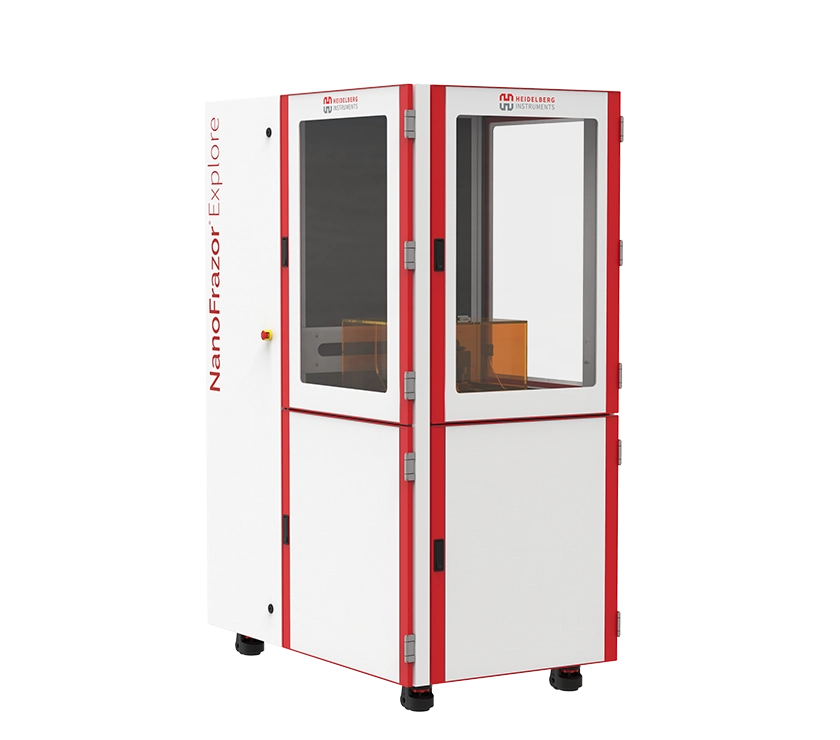

NanoFrazor Explore

- Thermal Scanning Probe Lithography System

Thermal scanning probe lithography tool with direct laser sublimation and grayscale modules. Excellent alternative to e-beam lithography tools.

NanoFrazor Scholar

- Thermal Scanning Probe Lithography System

Table-top thermal scanning probe lithography system with in-situ AFM imaging. Compact and compatible with glovebox.

ULTRA

- Laser Mask Writer

A tool specifically designed to produce mature semiconductor photomasks.

VPG+ 200 / VPG+ 400

- Volume Pattern Generator

A production tool for standard photomasks and microstructures in i-line resists.