The commercialization of the NanoFrazor started in 2012.

This article looks back at where the NanoFrazor came from, how it evolved over the last 10 years, and where it is heading now.

The origins of Thermal Scanning Probe Lithography

Already in the early 1990s, John Mamin and Dan Rugar from IBM Research Almaden, California showed that the sharp tips of atomic force microscopes can be heated and used as a tool to “drill” nanoscale holes. Triggered by these results, Peter Vettiger and Nobel laureate Gerd Binnig launched the Millipede project at IBM Research Zurich.

After a research period of more than 10 years, the Millipede project proved that thousands of heatable tips can be used to write, read, and delete data with high speed and record data storage density. The whole Millipede device was designed to fit inside an SD card and serve as a memory device, e.g., for future mobile phones. However, in the meantime FLASH memory showed improved performance and became very cheap to produce. Hence, the plans for commercialization of the Millipede device were stopped around 2007.

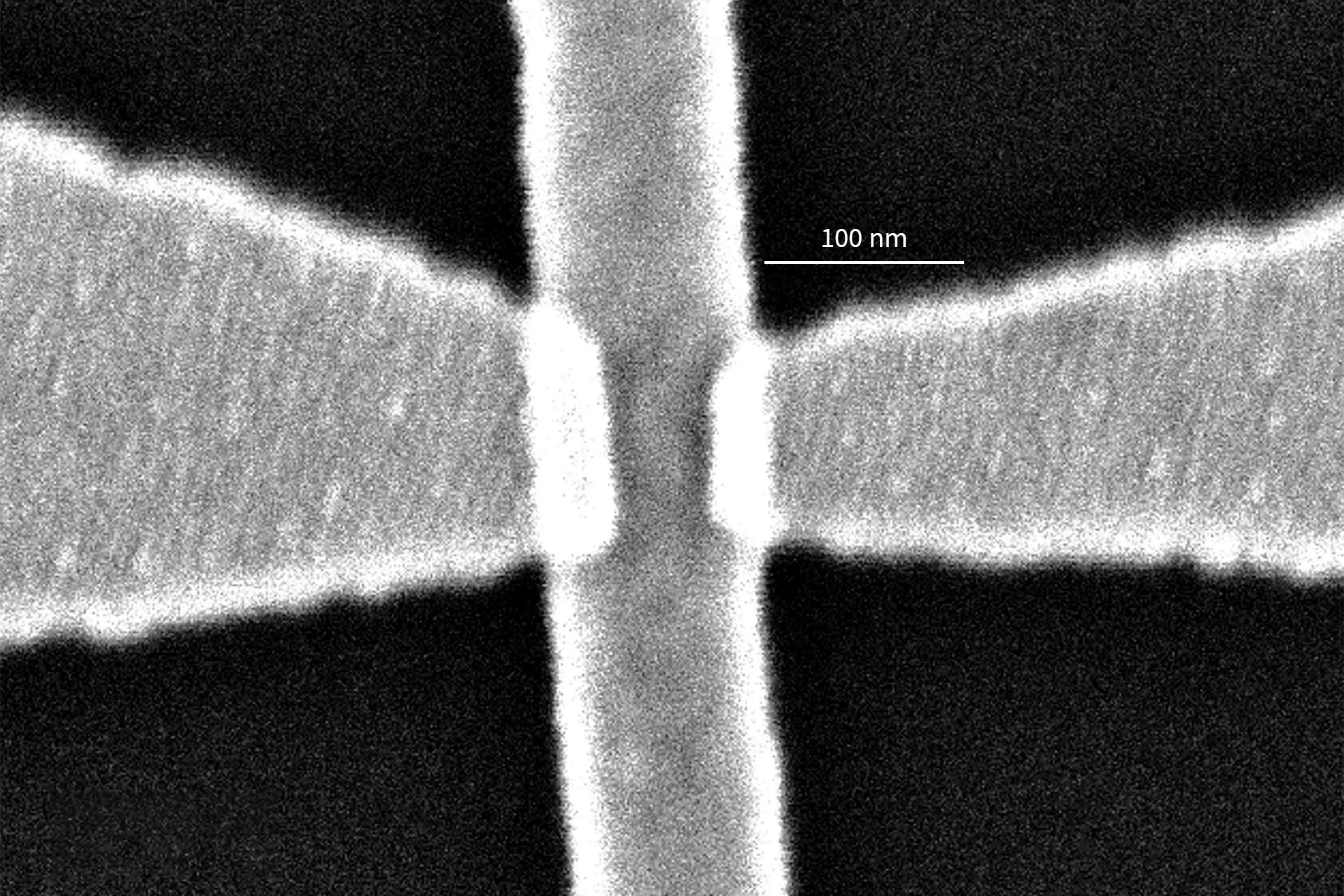

The team including Armin Knoll, Bernd Gotsmann, Urs Dürig, Ute Drechsler and Michel Despont at IBM Research continued to use the heatable tips developed during the Millipede project for various other applications. They discovered that it was possible to write arbitrary nanostructures by using special materials that evaporate rather than form mechanical indentations as used for the Millipede memory concept. This new method was called Thermal Scanning Probe Lithography.

In 2009 and 2010, Felix Holzner and Philip Paul joined the team at IBM to explore how this new concept with evaporating resist materials could be used for actual nanolithography applications. Aside from testing different material variations, they looked at the absolute limits of the patterning speed. Their research also investigated the advantages that originate from the unique in-situ imaging capability of the method for accurate 3D nanopatterning and stitching of patterning fields. The results were very encouraging, as some clear advantages over the most established nanolithography methods like electron beam lithography could be demonstrated.

In 2011, Felix Holzner explored various ideas of commercialization of the technology in a startup course at ETH Zurich. He participated in the business idea competition “venturekick” and won 10,000 CHF to start the realization of the business idea of selling nanolithography equipment for Thermal Scanning Probe Lithography.

Start of SwissLitho and the first NanoFrazor

In 2012, Felix Holzner and Philip Paul incorporated SwissLitho AG as CEO and CTO while still being employed at IBM Research. During that year, the business model was refined, different sources for funding evaluated, first potential customers approached, and a patent license agreement negotiated with IBM.

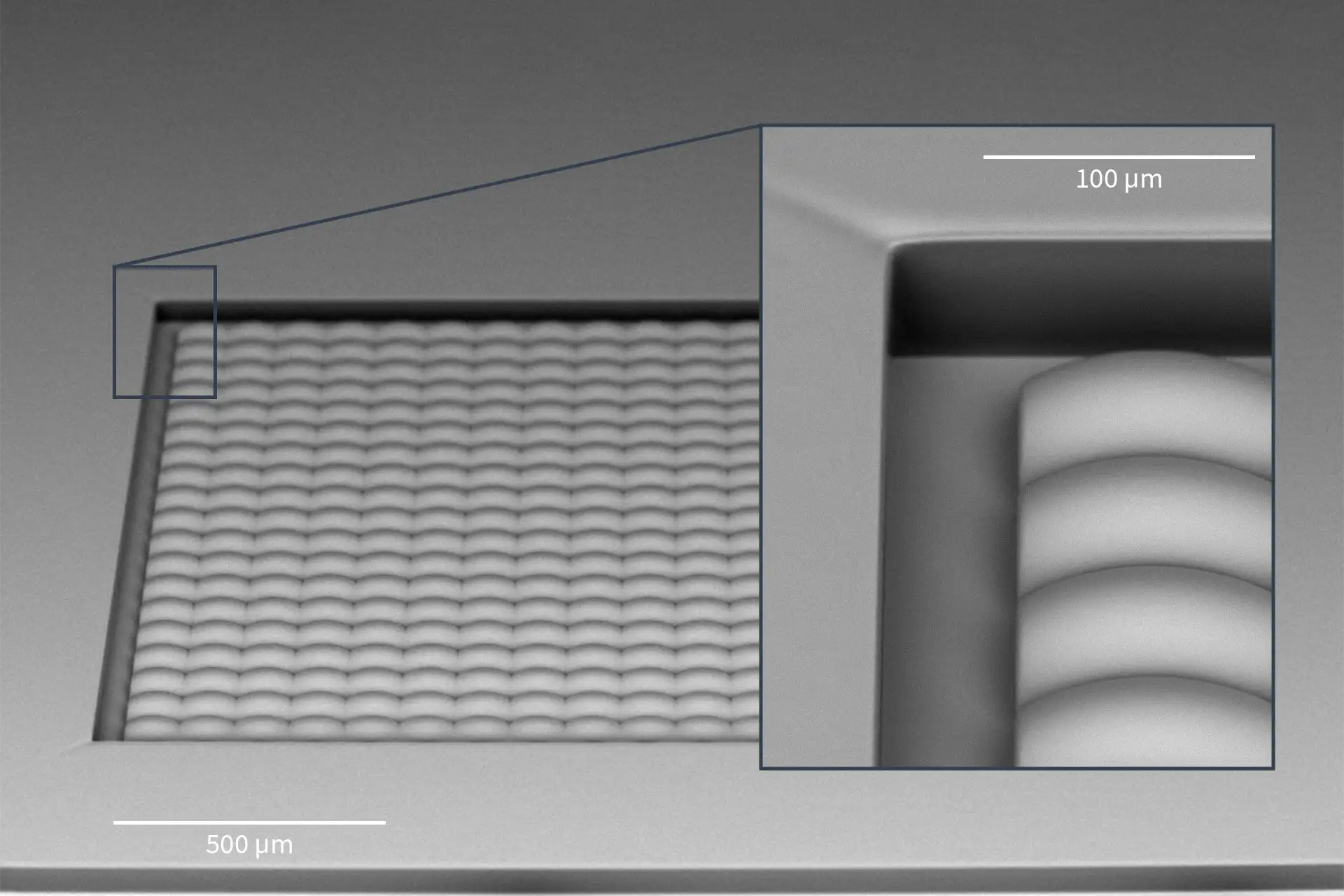

The technical term Thermal Scanning Probe Lithography was replaced by the commercial product name “NanoFrazor”. In this case, “Frazor” originates from the German word “Fräse” (milling machine) and the English word “razor” resembling the core of the technology: removing material with a very sharp tool.

In early 2013, Felix Holzner finished his PhD thesis about the NanoFrazor technology at ETH Zurich and the two founders left IBM to start operations of SwissLitho in a small office in Technopark Zurich. Kartik Buddha and Simon Bonanni joined them right from the start in Technopark, both absolute key members of the NanoFrazor team until today. The industrial designer Felix Fabian from Germany (who is now full-time at Heidelberg Instruments) helped them to move forward quickly with building the first commercial prototype of the NanoFrazor so that the young team managed to bring the 600 kg machine to the MNE conference in London in September 2013. They generated a lot of attention and interest at this important conference, even though this prototype was not able to write anything yet.

Funding for SwissLitho at that early time came from various startup awards and scholarships as well as federal and EU research grants. In 2014, SwissLitho generated its first revenue. The McGill University in Montréal, Canada and the EPFL in Lausanne, Switzerland received government grants to purchase the first systems. The very first NanoFrazor was named after the mountain “Titlis”. Its basic functions were working just in time before it was shipped to Montréal and successfully installed at McGill in June 2014.

More NanoFrazors spread over the world

From here on out, the company and the number of sold NanoFrazors continued to grow steadily. A global sales network was established by the NanoFrazor sales manager ZhengMing Wu. By the end of 2017, there were more than ten NanoFrazor systems installed in China, USA, Canada, Germany, Switzerland, Korea, Australia, and China. More than 15 scientists and engineers from more than ten countries worked for SwissLitho.

With the customers increasing, the audience of the annual “Thermal Probe Workshop” also grew, with nanotechnologists from all over world gathering to discuss the progress as well as the diverse opportunities and challenges of the novel technology. A clear highlight was the 2016 “Young Researcher Idea Contest” with close to 100 submissions of creative ideas how the NanoFrazor could be used (or misused). A jury of former professors selected three winners, who then had the chance to try to realize their ideas with support from SwissLitho. Two of the three unconventional ideas worked out well and led to great scientific publications.

At the end of 2017, SwissLitho introduced also a smaller and cheaper version of the NanoFrazor, the NanoFrazor Scholar, to make the basic capabilities of the technology also available for smaller research institutions with less funding available. The application range of the NanoFrazor greatly increased over time, ranging now from diverse applications in biology to novel kinds of magnetic, optical, electronic and quantum devices. The functionalities and capabilities of NanoFrazor systems were continuously improved and extended by software updates for all customers, usually at least twice a year, to cope with the extension of applications and customer demands.

Next to these direct improvements of the NanoFrazor, a strong focus of SwissLitho has always been on material and process development to support existing customers and convince new customers with various new applications. For this purpose and ever since its incorporation, SwissLitho has maintained a strong partnership with IBM Research and some key customers to develop new processes for the NanoFrazor. This effort paid off, as several customers achieved breakthrough scientific results that have only been enabled by the unique capabilities of the NanoFrazor and hence led to high impact publications in journals like Science or Nature. Researchers clearly benefit most from the NanoFrazor for rapid prototyping of nanodevices often with novel functionalities. But also interest from industry increased and a first NanoFrazor was shipped to a large semiconductor company in Asia in 2019.

Becoming a part of Heidelberg Instruments and Lab14

In December 2017, Heidelberg Instruments Mikrotechnik GmbH offered to acquire the majority of SwissLitho. The offer was not only very attractive from a monetary point of view, but the two companies also identified obvious synergies for market exploration and their respective technologies. Another consideration was that Heidelberg Instruments is itself owned by the German RAG foundation. Aside from promoting projects in education and culture, they focus on funding technologies of the future to finance perpetual obligations that the hard coal mining industry has left behind. This structure guarantees sustainable long-term conditions for their companies, which are beneficial for the employees as well as the customers. For these good reasons, the share purchase agreement was signed by the 25 shareholders of SwissLitho in March 2018.

Already by the end of the first year after the acquisition, a first prototype of an integrated laser writer for the NanoFrazor was jointly developed by SwissLitho and Heidelberg Instruments and shipped to customers in 2019. The production of the NanoFrazor systems was gradually integrated into the large and professional production facility in Heidelberg.

In 2021, SwissLitho changed its name to Heidelberg Instruments Nano and moved to a larger and brand-new office and laboratory in Zurich. The focus of the team in Zurich is now mainly on various research and development projects to further improve the NanoFrazor systems and processes, as well as providing customer benchmarks and demonstrations and advanced customer support.

These activities are managed now by Emine Cagin as CTO and Matthias Bürke as CFO of Heidelberg Instruments Nano. Philip Paul has moved to Heidelberg to have an eye on the NanoFrazor production, but mainly to manage the development and commercialization of the MLA 300, a new strategic high-throughput mask-less lithography system for industrial applications. Felix Holzner stepped back as CEO of Heidelberg Instruments Nano and took the opportunity to join the recently formed company group Lab14 as Head of Technology and Innovation. In this position, he remains located in the offices at Heidelberg Instruments Nano in Zurich, but now works for all the companies of Lab14. Within Lab14, he intends to make use of the technological synergies among the various newly acquired and soon to be acquired companies of Lab14, who are all actively pursuing complementary innovative products and solutions required for nano- and microfabrication. Also, the next generations of NanoFrazo systems will benefit from such synergies within Lab14 and in addition the NanoFrazor is also likely to become a crucial ingredient for the long-term strategy of the whole Lab14 group.

NanoFrazor today and tomorrow

The first installed commercial NanoFrazor machine from 2014 – the “Titlis” – is still running at McGill university. Just at the end of May 2022, McGill received an upgrade of their NanoFrazor Explore system with the integration of the laser writer unit.

Today, more than 50 NanoFrazor systems have been installed all over the world and new customers are already lined up for new systems.

The demand to use the principal capabilities of the NanoFrazor also over larger areas is enormous for various different applications. However, the biggest limitation of the current NanoFrazor systems remains the limited throughput, which at the moment prevents a deeper market penetration in several directions. The development team in Zurich is therefore working on different promising solutions on the instrument as well as on the materials to overcome the origins for these limitations in throughput.

From this perspective of the still manifold open opportunities for the NanoFrazor technology, the NanoFrazor technology can still be considered to be in its infancy even 10 years after the start of its commercialization. We are all excited to see how the NanoFrazor will look like in 10 years from now, when it certainly has reached maturity.