Photomasks

Masks in Photolithographic Production

-

Description

-

A photomask serves as a template or stencil in the photolithographic production of integrated circuits by displaying their pattern. It is extensively used in the manufacturing of high-end electronic components, semiconductor devices, displays, and other similar applications. Despite the constant reduction in the size of transistors, photomask-based UV lithography remains the industry-standard technique for micro-fabrication.

Typically, a photomask comprises a soda-lime or quartz plate coated with metal and transparent openings. The metal absorbs light at various wavelengths, with chrome commonly used as the absorption material for i-, g-, and h-line. The transparent image on the photomask represents the master template, and the pattern is transferred to a photosensitive layer through photolithography using a mask aligner or stepper. To produce a complete device for semiconductor or display manufacturing, a set of photomasks is required. In semiconductor manufacturing, the photomask is protected by a foil (pellicle) to prevent contamination.

The pattern on the photomask is created by laser lithography or e-beam lithography, depending on the resolution requirements. As the master template for photolithographic manufacturing, the photomask must meet rigorous specifications, such as linewidth uniformity, pattern position accuracy, edge roughness, and minimum feature size. Additionally, the photomask specifications must be considerably tighter than the target application to enable a large process window for the final process.

In addition to its direct write capability, Heidelberg Instruments’ VPG+ systems are high-volume pattern generators that can produce high-precision photomasks with exceptional image quality.

The ULTRA is a certified laser mask writer for established semiconductor photomasks manufacturer and can create structures as small as 500 nm.

-

Requirements

-

Tight CD uniformity and low edge roughness, considerably better than required for the final application

Precise pattern positioning and plate-to-plate accuracy to enable accurate alignment of multilayer structures

Good Mura conditions to avoid disturbances in regular periodic patterns, especially for display applications

High repeatability to ensure stable photomask quality

-

Solutions

-

High resolution

enabled with meticulously designed optical paths and real-time autofocusTight CD Uniformity

achieved through the integration of electronically controlled pattern illuminationSmooth edge roughness

obtained through intelligent sub-pixelizationHigh placement accuracy and reduced Mura effects

achieved through live high-precision measurement of position and corrective adjustments of deviations

A photomask serves as a template or stencil in the photolithographic production of integrated circuits by displaying their pattern. It is extensively used in the manufacturing of high-end electronic components, semiconductor devices, displays, and other similar applications. Despite the constant reduction in the size of transistors, photomask-based UV lithography remains the industry-standard technique for micro-fabrication.

Typically, a photomask comprises a soda-lime or quartz plate coated with metal and transparent openings. The metal absorbs light at various wavelengths, with chrome commonly used as the absorption material for i-, g-, and h-line. The transparent image on the photomask represents the master template, and the pattern is transferred to a photosensitive layer through photolithography using a mask aligner or stepper. To produce a complete device for semiconductor or display manufacturing, a set of photomasks is required. In semiconductor manufacturing, the photomask is protected by a foil (pellicle) to prevent contamination.

The pattern on the photomask is created by laser lithography or e-beam lithography, depending on the resolution requirements. As the master template for photolithographic manufacturing, the photomask must meet rigorous specifications, such as linewidth uniformity, pattern position accuracy, edge roughness, and minimum feature size. Additionally, the photomask specifications must be considerably tighter than the target application to enable a large process window for the final process.

In addition to its direct write capability, Heidelberg Instruments’ VPG+ systems are high-volume pattern generators that can produce high-precision photomasks with exceptional image quality.

The ULTRA is a certified laser mask writer for established semiconductor photomasks manufacturer and can create structures as small as 500 nm.

Tight CD uniformity and low edge roughness, considerably better than required for the final application

Precise pattern positioning and plate-to-plate accuracy to enable accurate alignment of multilayer structures

Good Mura conditions to avoid disturbances in regular periodic patterns, especially for display applications

High repeatability to ensure stable photomask quality

High resolution

Tight CD Uniformity

Smooth edge roughness

High placement accuracy and reduced Mura effects

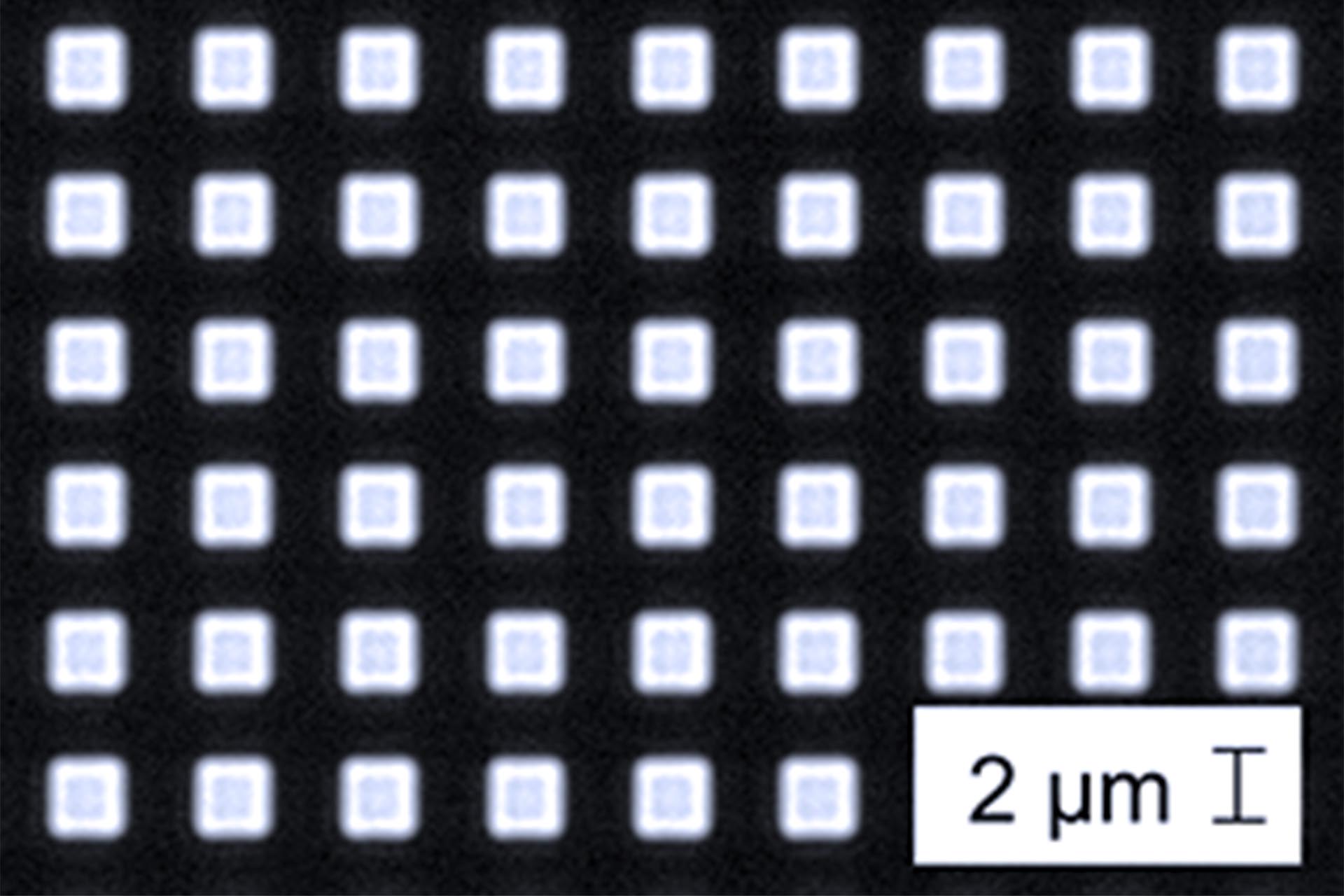

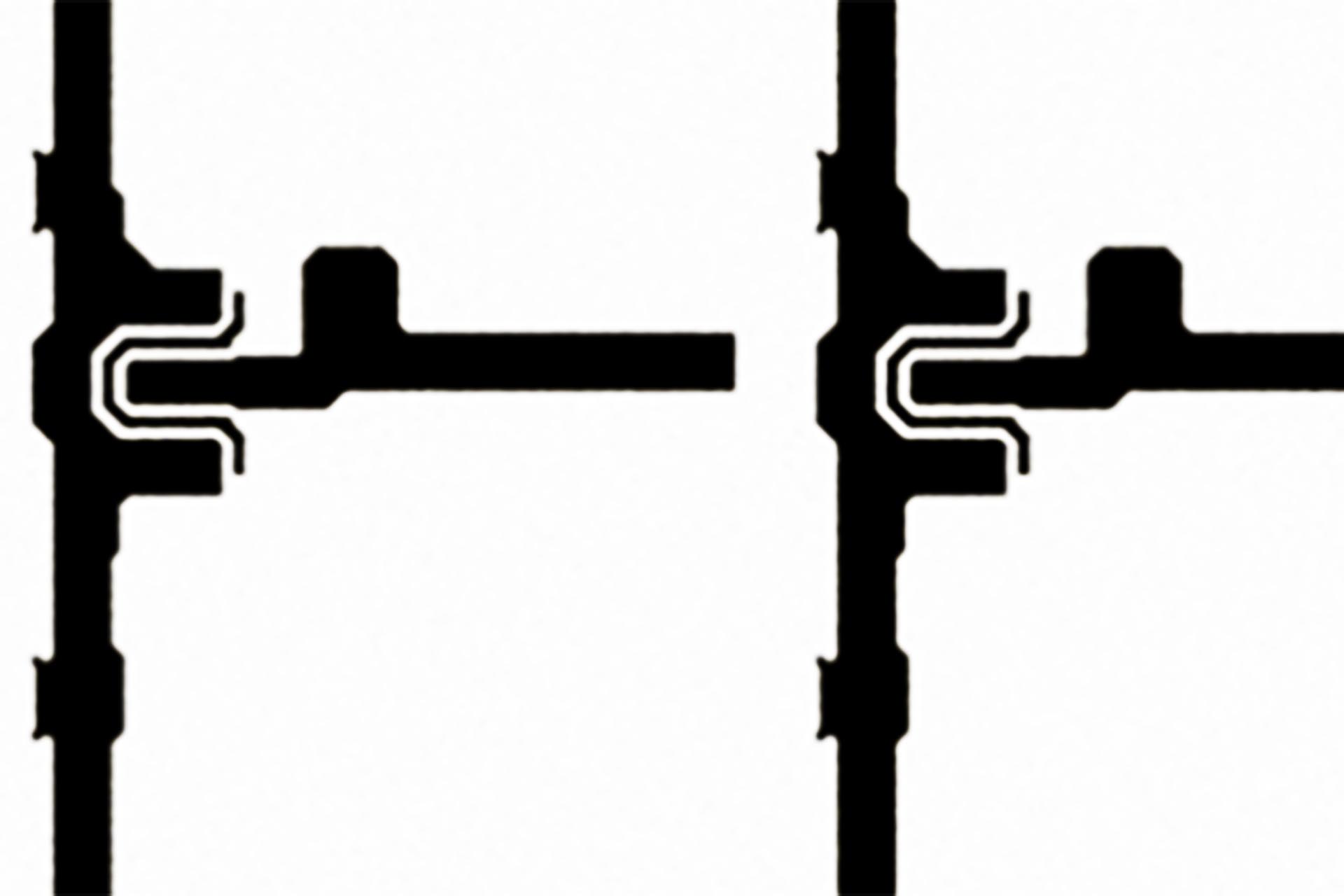

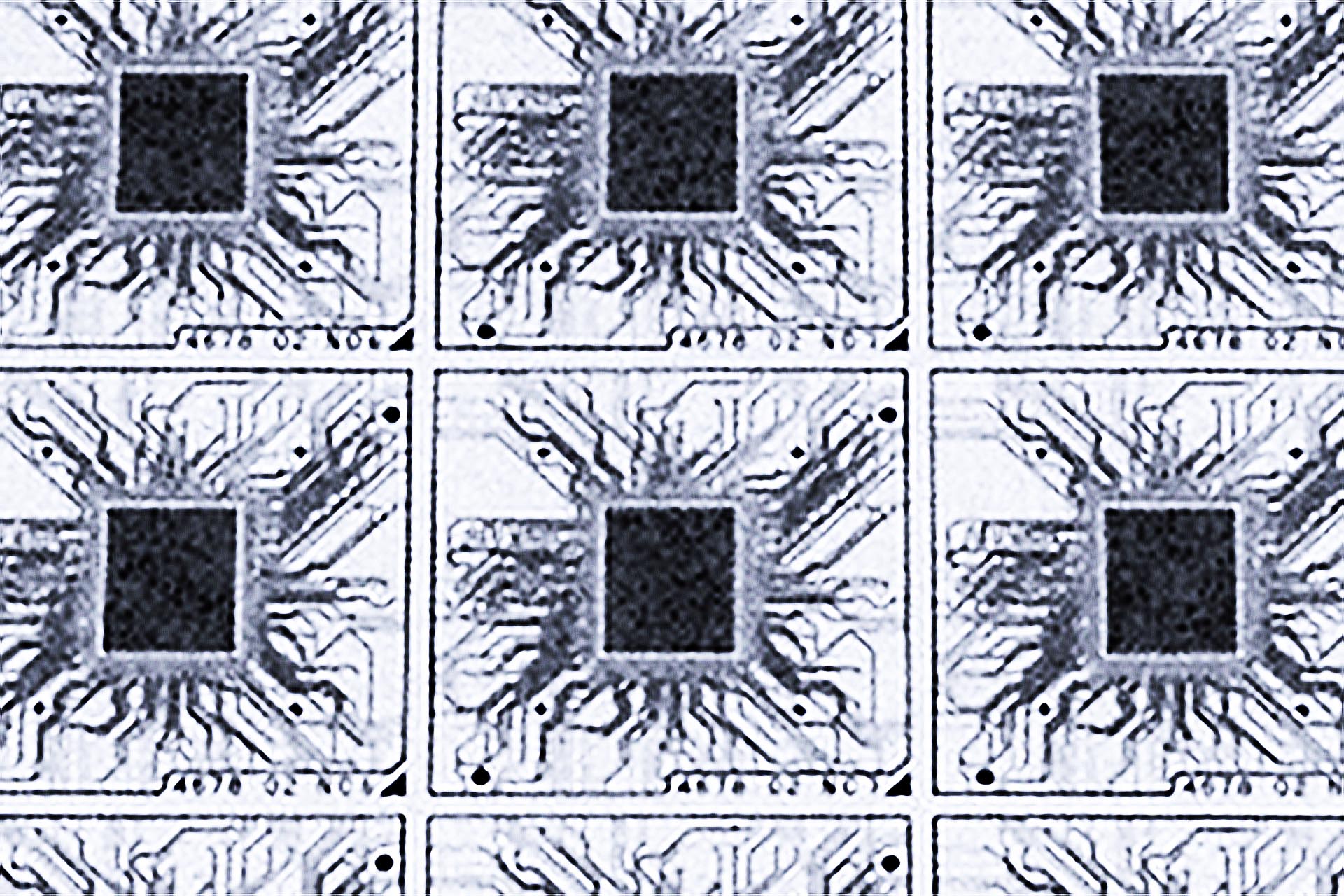

Application images

suitable Systems

ULTRA

- Laser Mask Writer

A tool specifically designed to produce mature semiconductor photomasks.

VPG+ 200 / VPG+ 400

- Volume Pattern Generator

A production tool for standard photomasks and microstructures in i-line resists.

VPG+ 800 / VPG+ 1400

- Volume Pattern Generator

Photomask production on large substrates, perfect for display applications.

VPG 300 DI

- Maskless Stepper

Maskless direct imager for high-accuracy and high-resolution microstructures.