Microfluidics and Nanofluidics

Precision Fluid Manipulation

-

Description

-

Microfluidics and nanofluidics are rapidly growing fields that involve manipulating small volumes of fluids in channels with micrometer and nanometer dimensions, respectively. These technologies find extensive applications in chemical and biological research, medical diagnostics, and industrial settings and enable the development of lab-on-a-chip devices, offering miniaturized platforms for chemical and biological reactions.

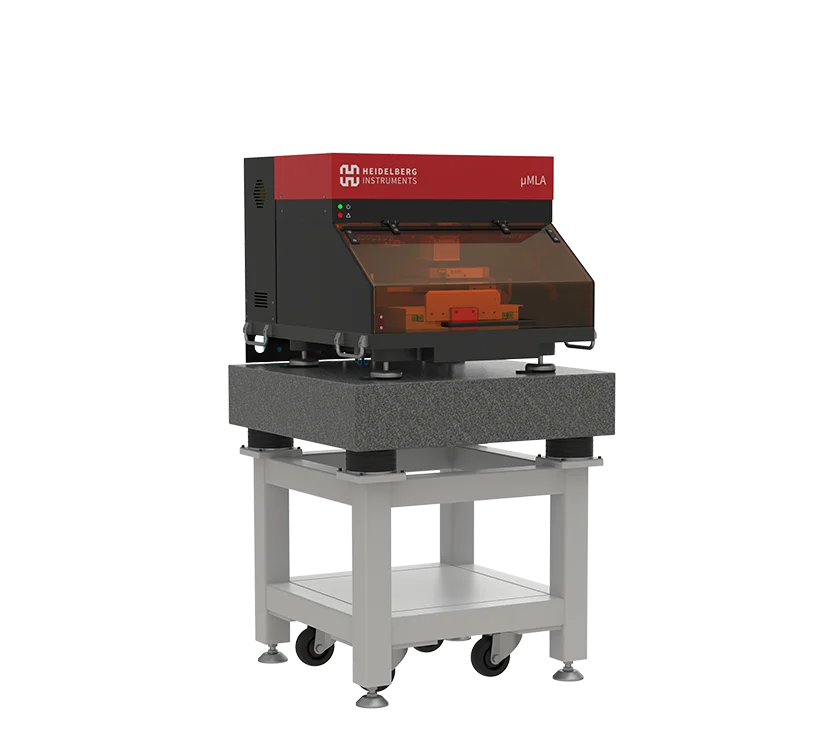

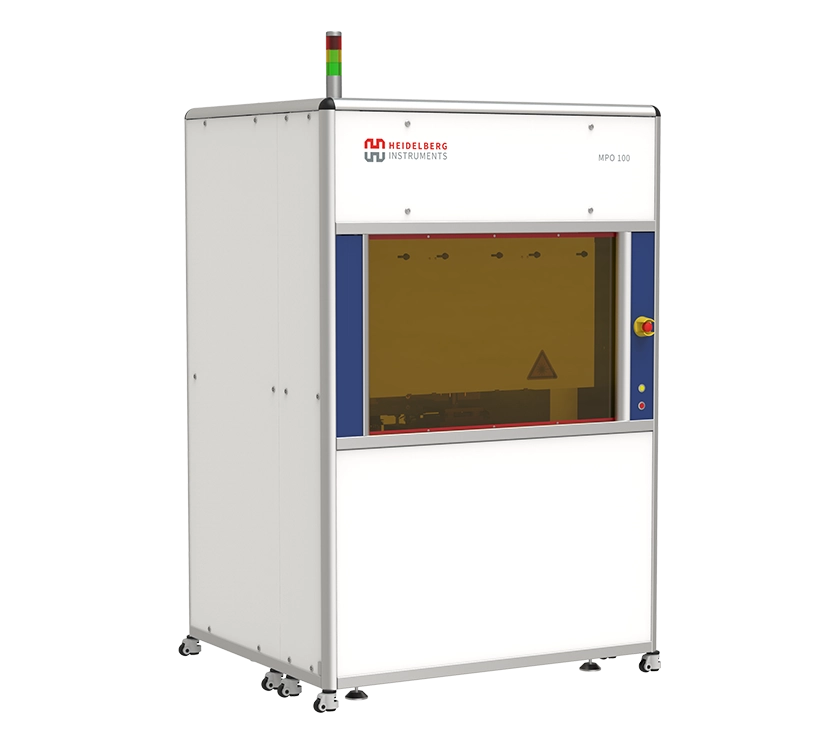

These devices provide advantages like reduced sample volumes, faster reaction times, and enhanced sensitivity, making them valuable in drug discovery, point-of-care diagnostics, and environmental monitoring. Microfluidic devices can feature various structures, and fabrication materials include SU-8 and mr-DWL resists, patterned using direct-write lithography tools like DWL and MLA series. For complex 3D structures, the MPO 100 utilizes two-photon polymerization.

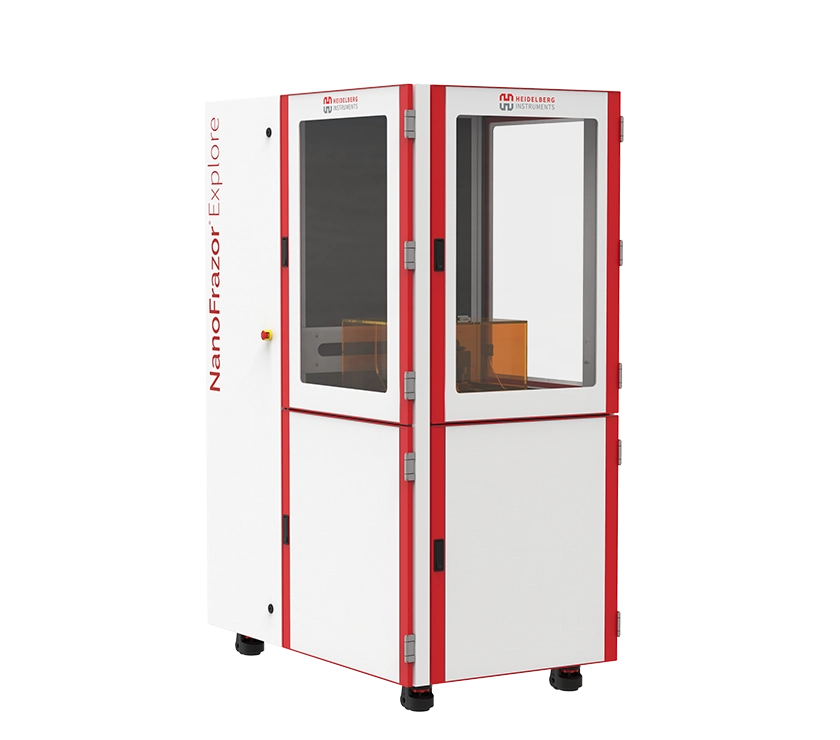

On the other hand, nanofluidics is crucial in nano- and biotechnology applications, where precise handling of tiny liquid volumes is necessary. It encompasses DNA sequencing, sorting, assembling, and manipulating nanoparticles, proteins, enzymes, and viruses. Nanofluidic structures demand excellent shape control, and various materials, including biocompatible polymers and epoxies, can be used. The NanoFrazor employs grayscale patterning capabilities, enabling efficient creation of nanofluidic systems. Its closed-loop lithography approach and integrated topography sensor ensure high accuracy and ultrahigh resolution, making it advantageous for nanofluidics applications. As technology advances, microfluidics and nanofluidics are set to play increasingly vital roles in various fields, from basic research to medical diagnostics.

-

Requirements

-

Smooth surface

High aspect ratio structures

Ultra-high-resolution holes and channels

Accurate grayscale lithography for channels (particles guiding)

-

Solutions

-

High resolution (DWL & MLA series) and ultra-high resolution (NanoFrazor)

Pattern small-diameter holes and narrow channelsGrayscale lithography (DWL series, µMLA & NanoFrazor)

Used to pattern either simple or complex 2.5D topographies (e.g., tapered channels)3D microstructures (MPO 100)

High aspect ratio

Tall channels with vertical side walls (MLA series)No undercut

The structure can be used for replicationNanoscale thermal conversion (NanoFrazor)

E.g., local binding of amine groups

Microfluidics and nanofluidics are rapidly growing fields that involve manipulating small volumes of fluids in channels with micrometer and nanometer dimensions, respectively. These technologies find extensive applications in chemical and biological research, medical diagnostics, and industrial settings and enable the development of lab-on-a-chip devices, offering miniaturized platforms for chemical and biological reactions.

These devices provide advantages like reduced sample volumes, faster reaction times, and enhanced sensitivity, making them valuable in drug discovery, point-of-care diagnostics, and environmental monitoring. Microfluidic devices can feature various structures, and fabrication materials include SU-8 and mr-DWL resists, patterned using direct-write lithography tools like DWL and MLA series. For complex 3D structures, the MPO 100 utilizes two-photon polymerization.

On the other hand, nanofluidics is crucial in nano- and biotechnology applications, where precise handling of tiny liquid volumes is necessary. It encompasses DNA sequencing, sorting, assembling, and manipulating nanoparticles, proteins, enzymes, and viruses. Nanofluidic structures demand excellent shape control, and various materials, including biocompatible polymers and epoxies, can be used. The NanoFrazor employs grayscale patterning capabilities, enabling efficient creation of nanofluidic systems. Its closed-loop lithography approach and integrated topography sensor ensure high accuracy and ultrahigh resolution, making it advantageous for nanofluidics applications. As technology advances, microfluidics and nanofluidics are set to play increasingly vital roles in various fields, from basic research to medical diagnostics.

Smooth surface

High aspect ratio structures

Ultra-high-resolution holes and channels

Accurate grayscale lithography for channels (particles guiding)

High resolution (DWL & MLA series) and ultra-high resolution (NanoFrazor)

Grayscale lithography (DWL series, µMLA & NanoFrazor)

3D microstructures (MPO 100)

High aspect ratio

No undercut

Nanoscale thermal conversion (NanoFrazor)

Application images

suitable Systems

MLA 150

- Maskless Aligner

The fastest maskless tool for rapid prototyping, the alternative to the mask aligners. Perfect for standard binary lithography.

DWL 66+

- Direct Write Laser Lithography System

Our most versatile system for research and prototyping with variable resolution and wide selection of options.

DWL 2000 GS / DWL 4000 GS

- Direct Write Laser Lithography System

The most advanced industrial grayscale lithography tool on the market.

MPO 100

- Two-Photon Polymerization Multi-User Tool

Multi-User Tool for 3D Lithography and 3D Microprinting of microstructures with applications in micro-optics, photonics, micro-mechanics and biomedical engineering.

NanoFrazor Explore

- Thermal Scanning Probe Lithography System

Thermal scanning probe lithography tool with direct laser sublimation and grayscale modules. Excellent alternative to e-beam lithography tools.

NanoFrazor Scholar

- Thermal Scanning Probe Lithography System

Table-top thermal scanning probe lithography system with in-situ AFM imaging. Compact and compatible with glovebox.