The oldest light in the Universe is called Cosmic Microwave Background (CMB), or relic radiation. It began travelling through space when the universe became transparent enough for the electromagnetic radiation. CMB has “seen it all” and since its discovery about 50 years ago, gives us a unique glimpse into the events and physics of the early universe.

A few projects at the South Pole Telescope are geared to look at what CMB has to tell about how galaxies appeared and began forming clusters. Comparing the oldest galaxy clusters with younger ones, gives clues to what dark energy must be doing.

Clarence Chang, who is a professor at the U.S. Department of Energy’s Argonne National Laboratory, studies the early universe. His scope of work is unique: while aiming at understanding the formation of galaxy clusters, Prof. Chang leads the team that develops detectors for the South Pole Telescope.

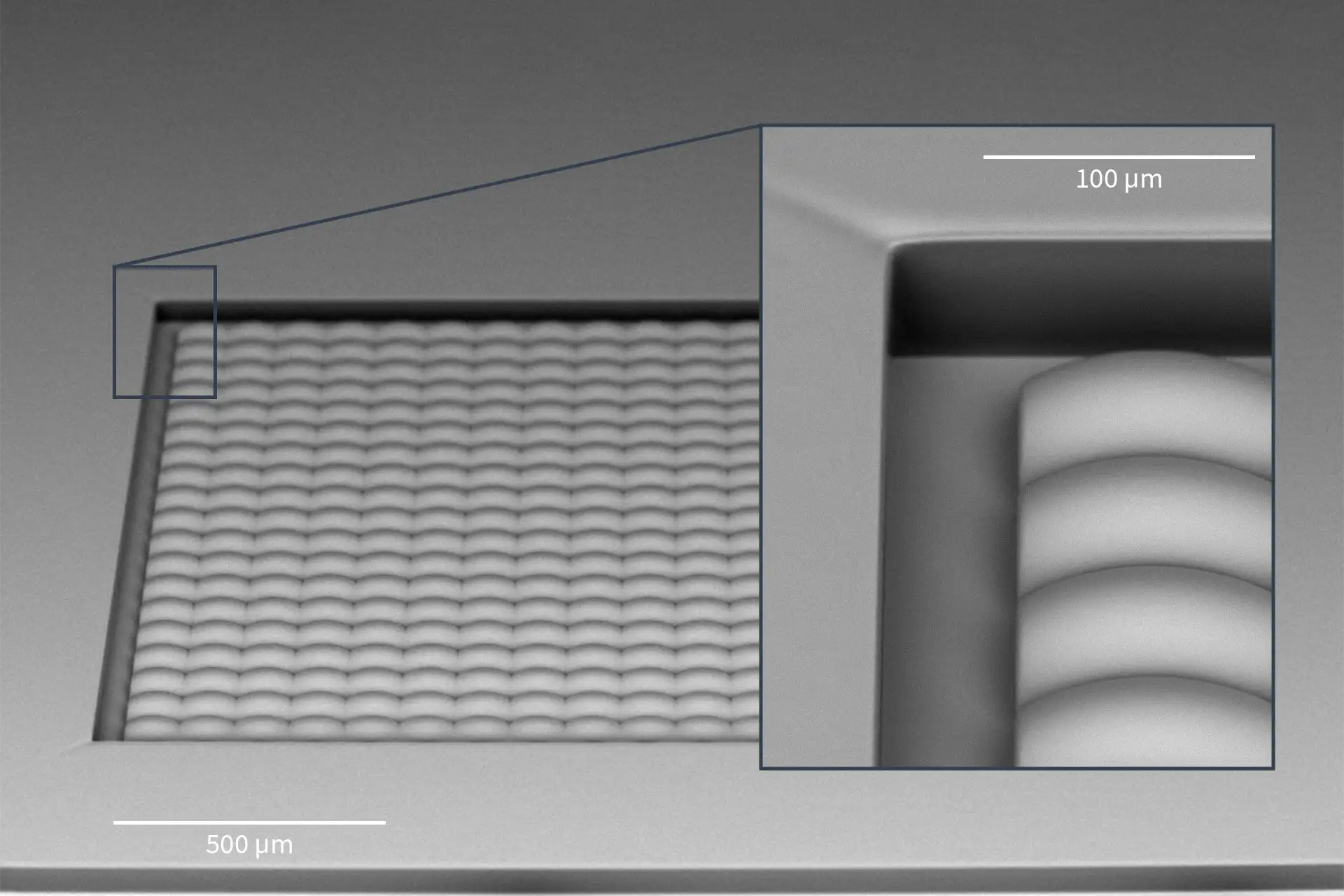

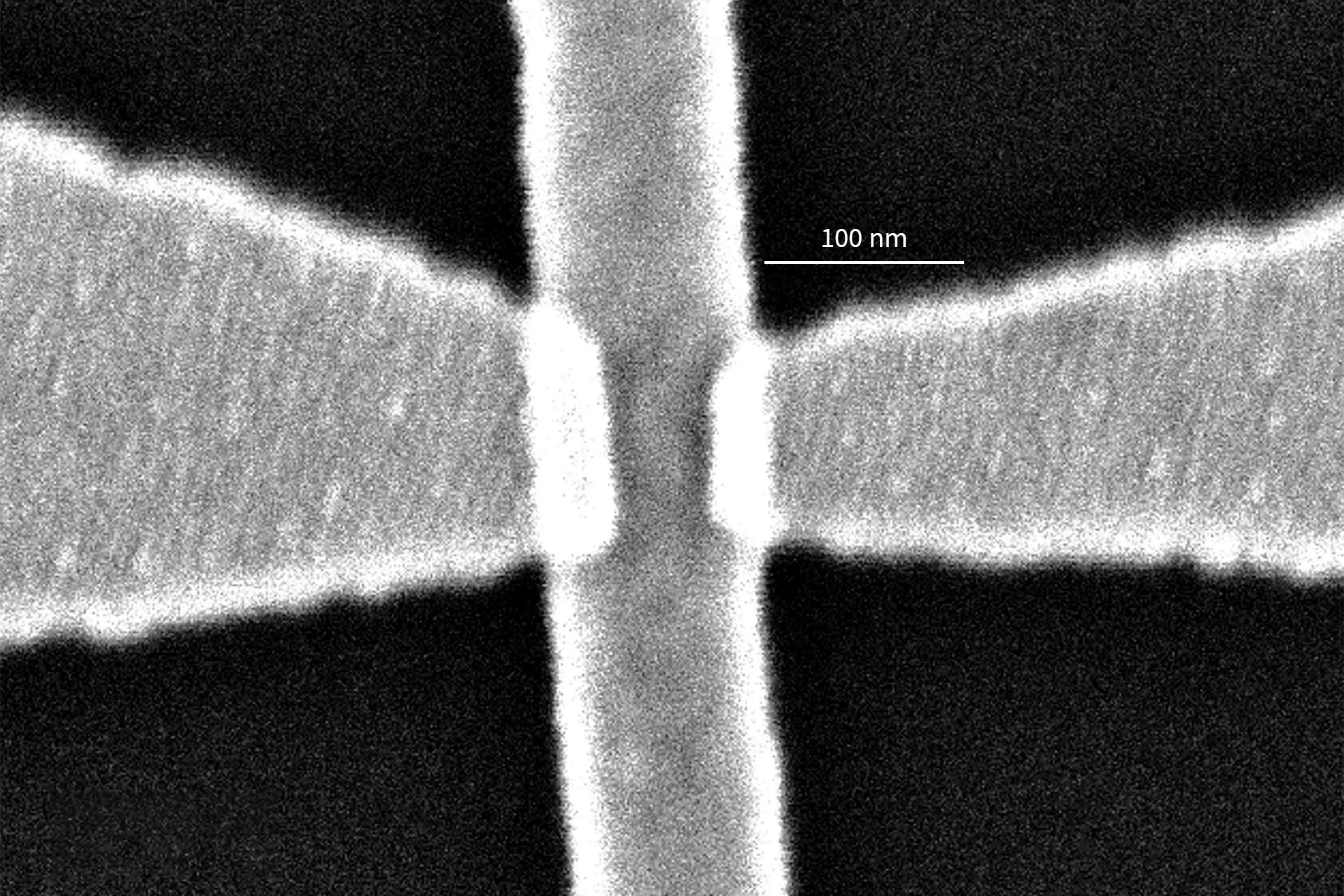

These detectors are based on superconducting transition-edge sensors and operate at cryogenic temperatures. Fabrication of these sensors takes about 20 process steps, some of which is done using MLA150 by Heidelberg Instruments. “Though Heidelberg Instruments did not realize they were making something perfect for us when developing MLA150 and MLA300 technology, they were.” – says Prof. Chang. – “We don’t need exceptional resolution, but we do want contact-free printing, very quickly. We’re basically trying to do for our detectors, what manufacturers do for cell phone cameras: we just want our stuff to go through the standardized process and roll out from the other side.” The result is robust wafer-scale detectors, installed at SPT and producing new physics for years.

In his interview to The Lithographer, Clarence Chang talks about the early universe and tells how intricate the nanofabrication of these detectors is. Spoiler alert: there is a beautiful view of the South Pole Telescope in the light of Aurora australis. Read the full interview with Prof. Chang in the Quantum issue of The Lithographer, p.8.

Read this edition in our libray:

Select “The Lithographer” in the Category filter.