Maskless Laser Lithography

Direct Writing on the Microscale

-

Description

-

Traditional photolithography requires the fabrication or purchase of a photomask and then the use of a stepper or mask aligner to transfer the CAD pattern onto a resist-covered wafer or plate. This process is the most established and feasible method for high-volume manufacturing of sub-micron sized design features. In fact, Heidelberg Instruments offers systems such as the VPG+ series or ULTRA that are specifically designed for the photomask market, from mature semiconductor photomasks, to electronics and FPD photomasks.

There is, however, another photolithography technique available which constitutes a perfect alternative for many other applications: Maskless Lithography. This state-of-the-art, high-precision, highly flexible technology is ideal for use in both R&D as well as environments where rapid-prototyping of feature sizes greater than 1 µm are required. The maskless lithography technique allows you to bypass the long process of ordering a photomask and enables you to transfer the design directly to the wafer without the need for a photomask.

In maskless lithography the pattern is exposed directly onto the substrate surface with the help of a spatial light modulator, or SLM, which serves as a “dynamic photomask”. Simply upload and convert the design file and the maskless aligner will take care of the rest. As your pattern evolves, simply reload the design and do as many exposures as is necessary over a much shorter period of time than what is possible with a traditional mask-based technique.

Discover our Maskless Aligners (MLA) and Direct Write Lithography (DWL) optical lithography systems.

Traditional photolithography requires the fabrication or purchase of a photomask and then the use of a stepper or mask aligner to transfer the CAD pattern onto a resist-covered wafer or plate. This process is the most established and feasible method for high-volume manufacturing of sub-micron sized design features. In fact, Heidelberg Instruments offers systems such as the VPG+ series or ULTRA that are specifically designed for the photomask market, from mature semiconductor photomasks, to electronics and FPD photomasks.

There is, however, another photolithography technique available which constitutes a perfect alternative for many other applications: Maskless Lithography. This state-of-the-art, high-precision, highly flexible technology is ideal for use in both R&D as well as environments where rapid-prototyping of feature sizes greater than 1 µm are required. The maskless lithography technique allows you to bypass the long process of ordering a photomask and enables you to transfer the design directly to the wafer without the need for a photomask.

In maskless lithography the pattern is exposed directly onto the substrate surface with the help of a spatial light modulator, or SLM, which serves as a “dynamic photomask”. Simply upload and convert the design file and the maskless aligner will take care of the rest. As your pattern evolves, simply reload the design and do as many exposures as is necessary over a much shorter period of time than what is possible with a traditional mask-based technique.

Discover our Maskless Aligners (MLA) and Direct Write Lithography (DWL) optical lithography systems.

Related images

Suitable Systems

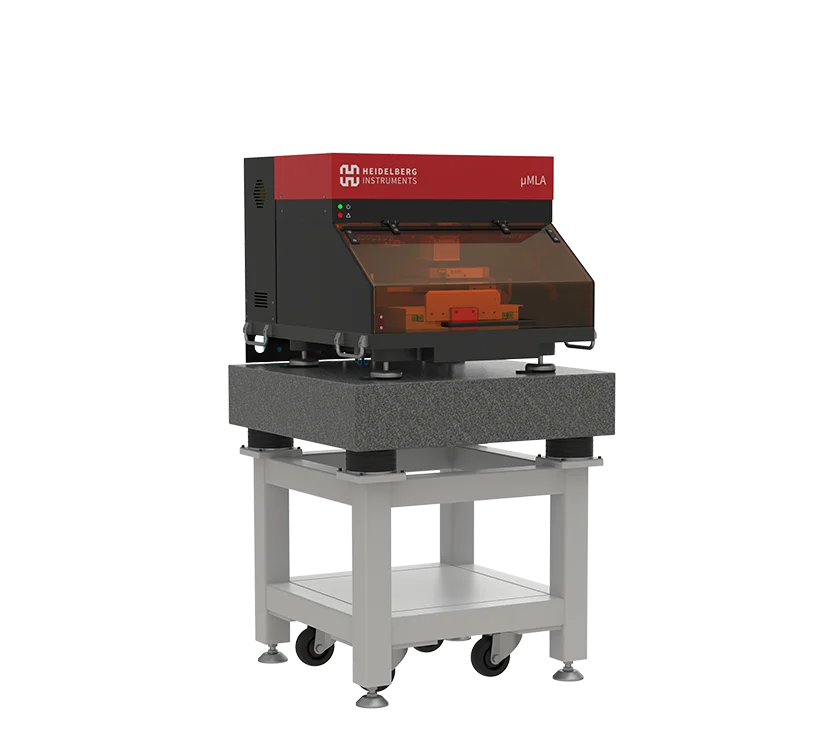

MLA 150

- Maskless Aligner

The fastest maskless tool for rapid prototyping, the alternative to the mask aligners. Perfect for standard binary lithography.

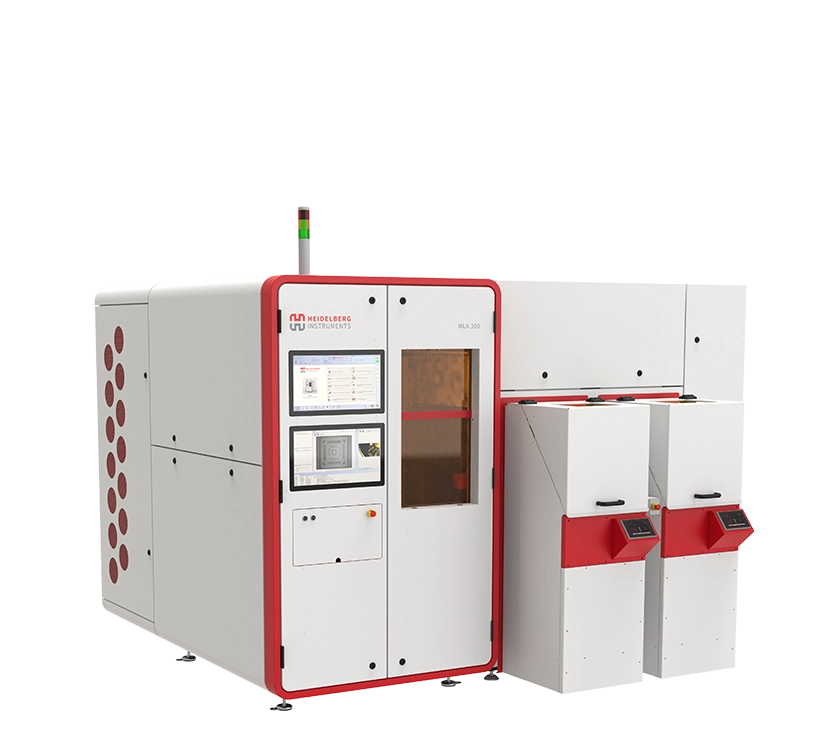

MLA 300

- Maskless Aligner

Optimized for industrial production with highest throughput and seamless integration into industrial production lines.

VPG+ 200 / VPG+ 400

- Volume Pattern Generator

A production tool for standard photomasks and microstructures in i-line resists.

DWL 66+

- Direct Write Laser Lithography System

Our most versatile system for research and prototyping with variable resolution and wide selection of options.

DWL 2000 GS / DWL 4000 GS

- Direct Write Laser Lithography System

The most advanced industrial grayscale lithography tool on the market.

VPG+ 800 / VPG+ 1400

- Volume Pattern Generator

Photomask production on large substrates, perfect for display applications.

ULTRA

- Laser Mask Writer

A tool specifically designed to produce mature semiconductor photomasks.